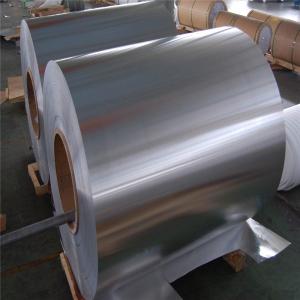

1050/1100/1070 1060 Aluminum Coil with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Coil 1060/1050/1100/1070

Chemical Composition:

| COMPOSITION % Percent | |||||||||

Si | Fe | Cu | Mn | Mg | Zn | Ti | Other elements | Al | ||

Each | Total | |||||||||

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | 0.040 | 0.030 | 0.03 | — | 99.70 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030 | 0.050 | 0.030 | 0.03 | — | 99.60 |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | 0.050 | 0.030 | 0.03 | — | 99.50 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | — | 0.100 | — | 0.05 | 0.15 | 99.00 | |

Applications:

High electro conductibility, and heat conductibility, good formability, bending and extending, commonly used for Chemical and food storage, electric conductor, soft pipe for brewing industry, heat exchanger, decoration etc.

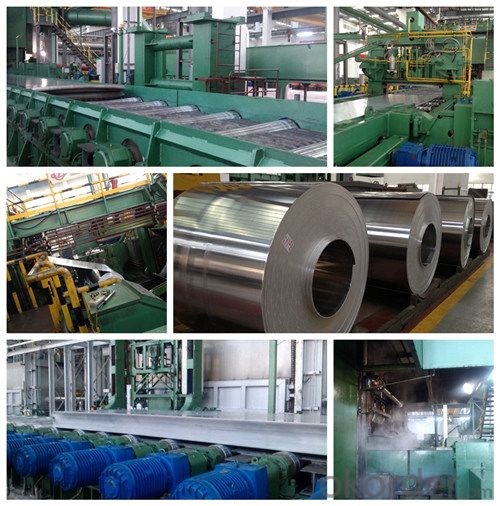

Production line:

- Q:wood aluminium windows?

- Wooden windows provide insulation, Aluminium windows failed the EU standards for insulation.

- Q:How are aluminum coils processed for specific mechanical properties?

- Aluminum coils are processed for specific mechanical properties through various methods such as heat treatment, cold working, and alloying. Heat treatment involves heating the coils to specific temperatures and then cooling them rapidly or slowly to enhance their strength, hardness, or ductility. Cold working, which includes processes like rolling or drawing, applies pressure to the coils to increase their strength and improve their mechanical properties. Alloying the aluminum coils with other elements can also modify their mechanical properties by enhancing their strength, corrosion resistance, or other desired characteristics. Overall, a combination of these processes is employed to achieve the desired mechanical properties in aluminum coils.

- Q:Can aluminum coils be customized to specific thicknesses and widths?

- Yes, aluminum coils can be customized to specific thicknesses and widths. Aluminum coils are often used in various industries such as construction, automotive, and aerospace, where specific dimensions are required for different applications. The customization process involves adjusting the thickness and width of the aluminum coils according to the customer's specifications. This can be done through a variety of methods, including rolling, slitting, or cutting the coils to the desired dimensions. Additionally, the customization process can also include other modifications such as surface treatments or coatings, depending on the application requirements.

- Q:How is Aluminum formed??Thanks!!

- I don't think any significant quantity of aluminum is produced by reduction with carbon - aluminum is too reactive for this to give a good yield. Instead, the metal is produced by electrolysis in the Hall-Heroult process. First, aluminum ore is processed to aluminum oxide in the Bayer process. This ore, bauxite, consists of aluminum oxides and hydroxides with some impurities, mostly iron oxides. The aluminum oxide/hydroxides are dissolved with concentrated sodium hydroxide in water. Iron oxides and hydroxides do not dissolve, and are filtered out. AlOOH (insoluble in water) + NaOH + H2O ----- NaAl(OH)4 (soluble in water) Neutralizing or cooling this solution will cause aluminum hydroxide to precipitate out. This is then heated strongly to drive off water and produce aluminum oxide. 2Al(OH)3 ----- Al2O3 + 3H2O This aluminum oxide can be melted and then electrolyzed to make the metal and oxygen gas. However, the melting point of aluminum oxide is very high, so it is dissolved in molten cryolite (Na3AlF6), which has a lower melting point. This is then electrolyzed, and molten aluminum collects at the bottom of the cell (cathode), where it can be drawn off. Because the oxygen that would be formed will attack most metal electrodes, a sacrificial carbon electrode is used for the anode and is oxidized to CO2. Very small amounts of aluminum metal occur in nature - it is usually found in association with fossil fuel deposits (which provide the reduced carbon necessary to reduce aluminum minerals).

- Q:Other than alloys. I'm trying to think of a way I can make an aluminum knife that will hold an edge. One group of researches say they used 60 metric tons of force to realign the molecular structure and give the metal strength equal to steel. I don't have a 60 ton press aha. Would heat treatment plus 10 tons of pressure repeated have a similar affect?

- Aluminum bronze is used commercially to make non-sparking knives. Why try to reinvent the wheel? I'm trying to think of a way I can make an aluminum knife that will hold an edge. You can strengthen aluminum by either cold working or heat treating a suitable alloy, but it will never be anything close to a good steel knife. Would heat treatment plus 10 tons of pressure repeated have a similar affect? No. Assuming that you are talking about the article linked to below: - you would have to duplicate the alloy process, even then you could only make a small thin sheet. They used a heat treatable alloy. The process involves torsional strain under 60 metric tons per square centimeter compression. How big a press do you think you would need for a knife size blank? And remember, you have to apply torsional cold work while compressing it. -Their results ( 1 gPA YS 5% elongation in a very thin sheet) don't look that great compared to a good knife steel. Or a good titanium knife.

- Q:Are there any limitations on the embossing of aluminum coils?

- Yes, there are limitations on the embossing of aluminum coils. The main limitations include the thickness and temper of the aluminum, as well as the complexity and depth of the desired embossing pattern. Additionally, the embossing process may affect the overall flatness and surface quality of the aluminum coil.

- Q:when ferrous sulfate is poured into an aluminium can, holes appear in the can. Why?

- aluminum reacts via a redox reaction with iron(II): 3 Fe2+(aq) + 2 Al(s) --- 3 Fe(s) + 2 Al3+(aq)

- Q:Can aluminum coils be used in the production of aluminum sandwich panels?

- Yes, aluminum coils can be used in the production of aluminum sandwich panels. Aluminum coils are typically used as the outer skins or facings of the sandwich panels. These coils are first processed and coated to enhance their durability, corrosion resistance, and aesthetic appeal. They are then bonded with a core material, such as polyethylene or mineral wool, to create a lightweight and rigid sandwich panel structure. The aluminum coils provide the panels with excellent mechanical properties, such as high strength-to-weight ratio, good flexibility, and thermal conductivity. Additionally, the use of aluminum coils in the production of sandwich panels allows for easy customization, as they can be formed, shaped, and painted according to the desired design and specifications.

- Q:what language did Aluminum and Uranium originate from ? Who or what were they named for ?

- The ancient Greeks and Romans used alumen (alum, potassium aluminium sulfate, K2Al6(OH)12(SO4)4) in medicine as an astringent, and as a mordant in dyeing. Alum was exported from ancient Greece and Italy. In 1761 the French chemist Louis-Bernard Guyton de Morveau (1737-1816) proposed the name alumine for the base in alum. Guyton de Morveau was instrumental in setting up a standardised system for chemical nomenclature and often collaborated with Antoine Lavoisier, who in 1787, suggested that alumine was the oxide of a previously undiscovered metal. In 1808, Sir Humphry Davy (1778-1829) did experiments for the decomposition of alumine, silex, zircone, and glucine. He failed to isolate the metals in these, as he reported in his paper for the Royal Society of London on 30 June 1808, but he suggested names for the metals (note) Cf. Silicium, Zirconium, and Beryllium (Glucium) Thus he proposed the name alumium for this still undiscovered metal and later agreed to change it to aluminum. Shortly thereafter the name aluminium was adopted to conform with the -ium ending of most elements. Uranium was named by its discoverer German chemist Martin Klaproth, after the last planet to have been discovered Uranus.

- Q:What are the advantages of using aluminum coils over other materials?

- There are several advantages of using aluminum coils over other materials. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This lightweight nature also makes it more cost-effective as it requires less energy to manufacture and install. Secondly, aluminum has a high level of corrosion resistance. It does not rust, even when exposed to harsh environmental conditions, making it suitable for outdoor applications. This durability ensures a longer lifespan and reduces maintenance costs in the long run. Additionally, aluminum coils provide excellent heat transfer properties. They have a high thermal conductivity, allowing for efficient heat exchange. This makes them ideal for applications such as heating, ventilation, and air conditioning systems, where effective heat transfer is crucial. Moreover, aluminum is a highly recyclable material. It can be recycled repeatedly without losing its quality or performance. This not only reduces waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer versatility in terms of design and customization. They can be easily formed, shaped, and coated to meet specific requirements. This flexibility allows for a wide range of applications in various industries, from automotive and construction to electronics and aerospace. Overall, the advantages of using aluminum coils, including its lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, make it a preferred choice over other materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1050/1100/1070 1060 Aluminum Coil with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords