Aluminum Coil Anodizing Positive Aluminium Coil T3-T6 & Aluminum Voice Coil Streamwood IL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

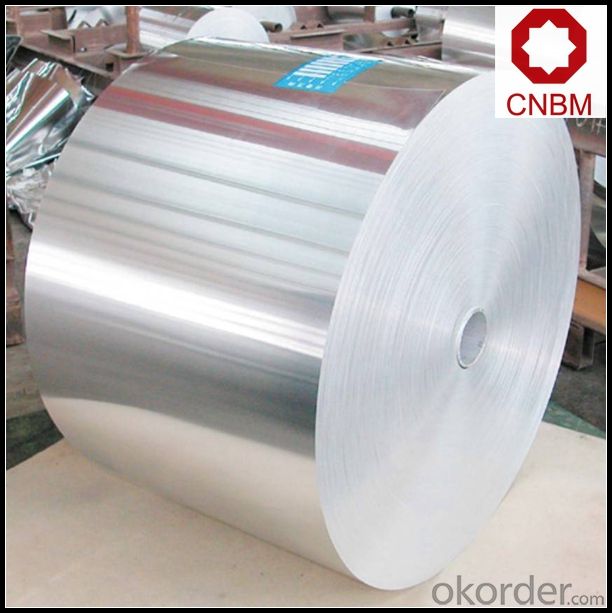

1. Specification of Positive Aluminium Coil T3-T6& Aluminum Voice Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Positive Aluminium Coil T3-T6& Aluminum Voice Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Positive Aluminium Coil T3-T6& Aluminum Voice Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

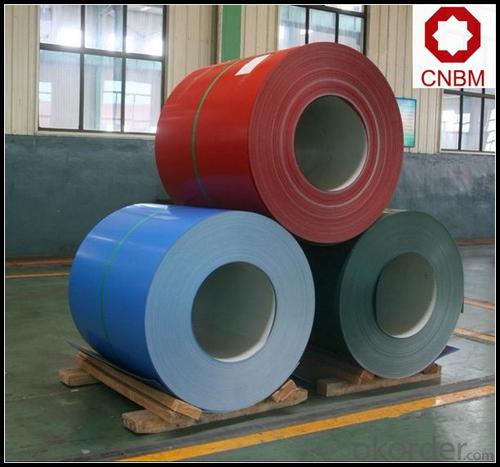

5. Image of Positive Aluminium Coil T3-T6& Aluminum Voice Coil

6. Package and shipping of Positive Aluminium Coil T3-T6& Aluminum Voice Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any health or safety concerns related to aluminum coils?

- Aluminum coils can pose some health and safety concerns, especially in certain circumstances. One potential concern is the release of aluminum particles or fumes into the air, particularly during the manufacturing or processing of aluminum coils. Inhalation of these particles or fumes can potentially lead to respiratory issues or lung damage. Additionally, aluminum coils that are damaged or corroded may release aluminum ions into food or beverages, which can be harmful if ingested in excessive amounts. However, it is important to note that the risks associated with aluminum coils are generally minimal and can be mitigated through proper handling and maintenance. For instance, manufacturers typically employ various safety measures to prevent the release of aluminum particles or fumes during production. Furthermore, aluminum coils used in heating, ventilation, and air conditioning systems are typically coated or treated to prevent corrosion and the subsequent leaching of aluminum ions. To minimize any potential health risks, it is recommended to follow safety guidelines provided by manufacturers, such as wearing appropriate protective gear during handling, and ensuring proper ventilation in areas where aluminum coils are processed or installed. Additionally, regular inspection, cleaning, and maintenance of aluminum coils can help identify and address any potential issues before they become a health or safety concern. In conclusion, while there are some health and safety concerns related to aluminum coils, these risks can be managed through proper handling, maintenance, and adherence to safety guidelines. It is always advisable to consult with professionals or manufacturers for specific instructions and recommendations related to the utilization and maintenance of aluminum coils in order to ensure maximum safety.

- Q: Would an SS scribe scratch an aluminum plate? What is the hardness value of both metals?

- SS and aluminium are available in very many shape and sizes SS is very much harder than aluminium aluminium has a hardness of 28 SS 90 to 100 Guru

- Q: Can aluminum coils be used in corrosive gas environments?

- Yes, aluminum coils can be used in corrosive gas environments. Aluminum is known for its excellent corrosion resistance, especially in atmospheric conditions. It forms a protective oxide layer on the surface that protects the metal from further corrosion. However, it is important to note that aluminum can be susceptible to certain corrosive gases, such as chloride and sulfur compounds. In such cases, additional protective measures, such as surface treatment or coating, may be necessary to ensure the longevity and performance of the aluminum coils in corrosive gas environments.

- Q: Can aluminum coils be used in the production of chemical storage tanks?

- Yes, aluminum coils can be used in the production of chemical storage tanks. Aluminum is a versatile and durable material that offers several advantages for chemical storage applications. It is corrosion-resistant, which makes it suitable for storing a wide range of chemicals. Additionally, aluminum is lightweight, which makes it easier to transport and install compared to other materials like steel. It is also non-magnetic, which can be beneficial in certain applications. However, it is important to consider the specific requirements of the chemicals being stored and consult with experts or manufacturers to ensure that aluminum is the appropriate choice for the intended use.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- wouldnt advise,it might bend Aluminium is a soft, lightweight metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nontoxic, nonmagnetic, and nonsparking. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[1] Aluminium has about one-third the density and stiffness of steel. It is ductile, and easily machined, cast, and extruded.

- Q: Is it safe to use steel wires for making jewelry or decorative items, and are there any potential health hazards associated with it?

- <p>Using steel wires for jewelry or decorations generally poses minimal health risks when used properly. However, there are a few considerations: allergic reactions can occur in individuals sensitive to nickel, which is often found in stainless steel. Additionally, improper use or sharp edges can lead to cuts or injuries. It's important to ensure that the steel is of high quality and that any jewelry made is smooth and free of sharp points to minimize the risk of injury. Regular cleaning and maintenance are also recommended to prevent any potential health risks associated with bacteria buildup or skin irritation.</p>

- Q: Aluminum roll, which companies are used?

- Too many things that you can see every day, with all the things that are made of aluminum, and the companies that make these aluminum products are useful, so it's unclear!

- Q: A bit of a question for the 1911 experts roaming around here. Per-say someone, who knew their way around a 1911 built one on an aluminum frame. To top it all off, if the finished gun were to be chambered in .38 super... how long would this combination last? I've heard horror stories about aluminum frames, and then I've heard some wonderful things... this question was to see if anyone had ever thought about/done this sort of thing before. Something tells me that Aluminum + .38 super wouldn't last too long... Most informative answer gets the ten point prize as usual.

- I have two concerns about using an aluminum frame for that caliber. First, and like everyone else who answered, I don't think it will stand up to the .38 Super +P for very long (and I wouldn't want to be around when it fails). Second, the reason I believe the frame will not last nearly as long as a steel or stainless (my personal suggestion) frame is that the grooves the slide fits and rides in will wear and enlarge MUCH faster than a steel or stainless frame will. This will, in my opinion, also quickly have an adverse affect on accuracy. Aluminum has it's place, but I don't think it's anywhere near this kind of firearm. On a side note, one of the other people who answered said that the aluminum will offer some corrosion resistance. This may generally be true, but salt water (like sweat) attacks aluminum significantly faster than it does steel, and stainless steel is almost non-reactive to it. If he wants a lighter gun for carry, Try an XD45. If I remember right they are rated for .45 +P, but call Springfield Armory to make sure. With the polymer frame they are much lighter than a 1911, and I have been very satisfied with the accuracy and the reliability of mine. Personally, I don't think the weight savings of the alloy frame is worth the extra care to keep from sweating on it or the much shorter lifespan the gun will likely have. If he isn't planning on carrying it, what is the point of lightening the gun? He'll feel a lot more recoil, especially if he does shoot the +P ammo.

- Q: What specific features or properties define aluminum coil?

- <p>Aluminum coil is characterized by its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. It is non-magnetic, has good thermal and electrical conductivity, and is highly malleable and ductile, making it easy to form into various shapes. Aluminum coil also has a shiny, reflective surface and is recyclable. It is commonly used in construction, automotive, packaging, and electrical applications due to these properties.</p>

- Q: i want to save some money on my electricity bill, and i heard that aluminum foil rejects the heat that goes through the windows, also does it work with the cold?

- If this is a house then it is your determination, if this is an condominium then you will greater advantageous verify with the administrative. maximum construction do no longer decide for aluminum foil on the residing house windows because it degrades the appearance of the residing house/condominium.

Send your message to us

Aluminum Coil Anodizing Positive Aluminium Coil T3-T6 & Aluminum Voice Coil Streamwood IL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords