Streamwood IL Aluminum Coil Anodizing - PE Coated Aluminium Coil for Curtain Wall AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

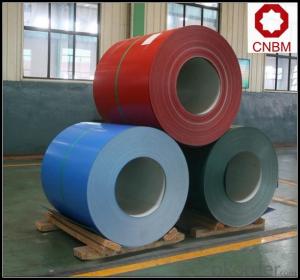

PE Coated aluminium coils are widly used in decoration field.Now we mainly exported to Asian countries and European countries.For the paint, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

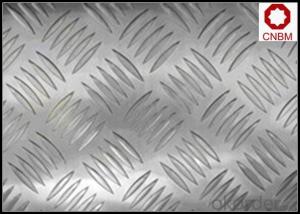

3.Image

4. Product Specification

| Alloy | Temper | Coating Thickness | Coil ID | Coil Weight |

| AA3003 | H14 | 22-25 MICRON | 505MM | 2.5 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 5 tons.

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: Can aluminum coils be used in packaging industries?

- Yes, aluminum coils can be used in packaging industries. Aluminum is lightweight, flexible, and has excellent barrier properties that protect the packaged products from moisture, oxygen, and light. It is commonly used for packaging food, beverages, pharmaceuticals, and other consumer goods due to its durability and ability to preserve product quality.

- Q: I am looking for a good comparison between carbon fiber and aluminum, we presently use aluminum in a lot of our manufacturing and may want to use cf. Does anyone have a simple breakdown of rough cost difference, weight savings, sheet thickness for a certain strength, that kind of thing, kind of struck-out looking on google unless I wanted a bike...Thanks in advance.

- If you google carbon fibre sheet you'll get more relevant hit. I found one which might help you with strength / mass comparison with the aluminium you currently using. Some more aspect you need to take into consideration: thermal resistance: carbon fibre does degrade quicker as temperature gets hotter. Water absorption: unless it's a really top quality carbon with good sealant resin, CF will absorb water and degrade in performance. Contamination by chemicals: see below. Oxidation: carbon fibre oxidise and looses strength as it oxidise. The oxidation level is quite low at room temperature but increases with temperature and also chemical contaminant Durability. as seen above CF will not have durability in time as you have with Aluminium. So be mindful as your product will not be as good in 10 years with CF as it is in Aluminium. Also failure mode with CF is much more difficult to predict, analyse and failure are not a controlled as Aluminium. CF will shatter when crack initiate from a minimal defect or chip.

- Q: What is the corrosion resistance of aluminum coils?

- Aluminum coils exhibit excellent corrosion resistance due to the formation of a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing further corrosion and providing long-term durability. The corrosion resistance of aluminum coils is further enhanced through various surface treatments and coatings, such as anodizing or painting, which provide an additional layer of protection. This makes aluminum coils a reliable choice for a wide range of applications in industries such as construction, automotive, and aerospace, where resistance to corrosion is essential.

- Q: What precautions should be taken when operating a welding torch on aluminum coils to ensure safety?

- <p>When using a welding torch with aluminum coils, it's crucial to follow safety measures to prevent accidents and ensure a safe working environment. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves, safety glasses, and a welding helmet. Ensure the work area is well-ventilated to avoid inhaling fumes. Use a backdraft hood or fume extraction system to capture and remove welding fumes. Keep the work area clean and free of flammable materials. Regularly inspect the torch for any damage or wear. Use the correct type of welding rod for aluminum and ensure the gas supply is compatible with aluminum welding. Never leave a lit torch unattended and always follow the manufacturer's guidelines for safe operation.</p>

- Q: Are aluminum coils suitable for automotive applications?

- Yes, aluminum coils are suitable for automotive applications. Aluminum coils offer several advantages such as lightweight, high corrosion resistance, and excellent heat conductivity, making them an ideal choice for various automotive components like radiators, condensers, and evaporators. The use of aluminum coils helps improve fuel efficiency, reduce emissions, and enhance overall vehicle performance.

- Q: My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- Aluminium is bad for you and too much aluminium can cause Alzheimer's disease and other problems. External deodorants are displaced by your perspiration and don't last long. Liquid chlorophyll is an internal deodorant that deodorises your body odours and perspiration odours before they come out of your pores. A table spoon of high strength liquid chlorophyll every day is all you need. Liquid chlorophyll also has a cooling effect so you perspire a bit less. You can find further information in a search for liquid chlorophyll + deodorant.

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

- Q: This question asks for the cost of a set of aluminum coils.

- <p>The cost of a set of aluminum coils can vary significantly based on factors such as the current market price of aluminum, the size and thickness of the coils, and the quantity being purchased. As of my last update, the price of aluminum fluctuates with the global commodities market, and it's best to check with suppliers or on metal exchange platforms for the most accurate and up-to-date pricing. For specific projects, you might need to contact aluminum suppliers directly to get a quote tailored to your requirements.</p>

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

Send your message to us

Streamwood IL Aluminum Coil Anodizing - PE Coated Aluminium Coil for Curtain Wall AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords