Aluminium Curtain Wall

Aluminium Curtain Wall Related Searches

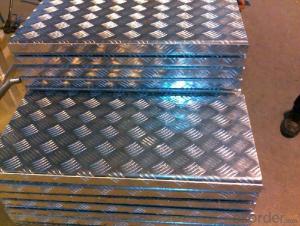

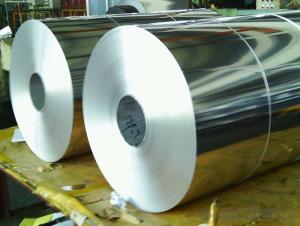

Seamless Curtain Wall Aluminum Wall Plate Curtain Wall Bedroom Partition Curtain Wall Pressure Plate Curtain Wall Aluminum Wall Panels Curtain Wall Backpan Curtan Wall Aluminium Circle Aluminum Exterior Wall Panels Aluminium Coating Aluminum Foil For Walls Aluminum Plate Wall Panels Aluminum Wall Panels Exterior Aluminium Tape Aluminum Sheet Circle Soundproof Curtains Curtain Panels Aluminum Awning Windows Aluminum Awnings Kitchen Wall Aluminum Foil Aluminum Gates Aluminium Checkered Plate Structural Silicone Glazed Curtain Wall Aluminum Fence Panels Aluminum Plate Acoustic Barrier Aluminum Plate Wallet Tape Aluminium Hydraulic Climbing Wall Cooking Aluminium CircleAluminium Curtain Wall Supplier & Manufacturer from China

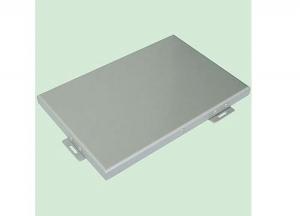

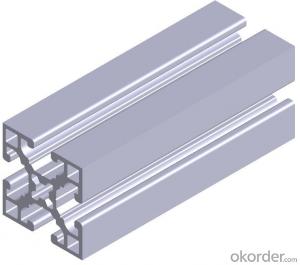

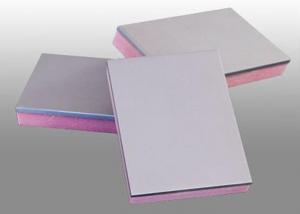

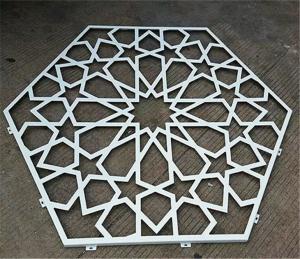

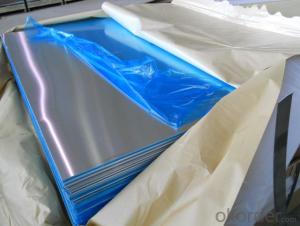

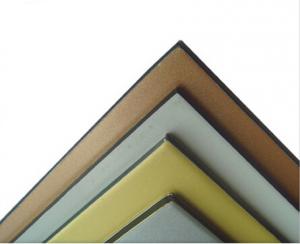

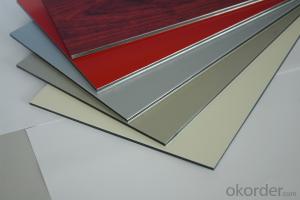

Aluminium Curtain Wall is a versatile and modern building product that consists of various components such as aluminum frames, glass, and other materials, designed to provide both aesthetic appeal and functional benefits to the structure. This product is widely recognized for its durability, energy efficiency, and low maintenance requirements, making it an ideal choice for a range of architectural applications. The Aluminium Curtain Wall can be found in numerous usage scenarios, including commercial buildings, residential high-rises, and public structures, where it serves to enhance the visual appeal and provide thermal insulation, thereby contributing to energy savings and a comfortable indoor environment.Okorder.com is a leading wholesale supplier of Aluminium Curtain Wall products, boasting a large inventory that caters to the diverse needs of clients across different industries. The company is committed to offering high-quality products at competitive prices, ensuring that customers receive the best value for their investment. With a comprehensive selection of Aluminium Curtain Wall options, Okorder.com is well-positioned to meet the specific requirements of each project, whether it's a small-scale renovation or a large-scale construction endeavor.

Hot Products