Powder Coated Mill Finish Aluminum Sheets for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

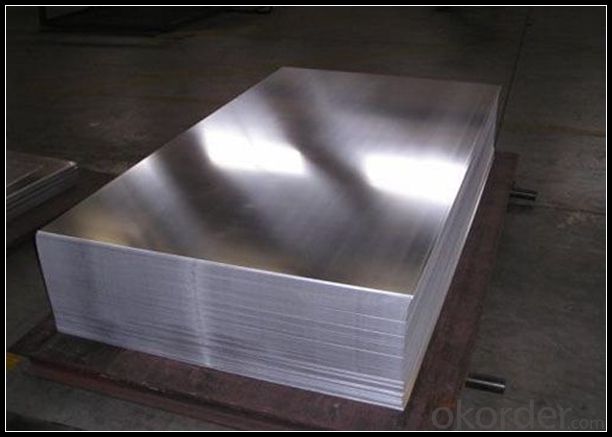

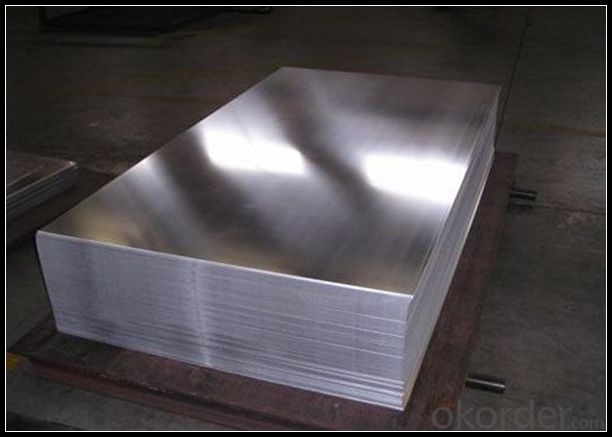

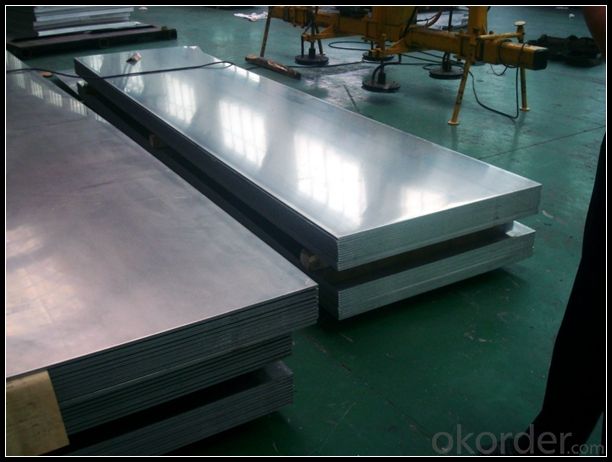

5. Image of Mill Finish Aluminium Sheet for Curtain Wall

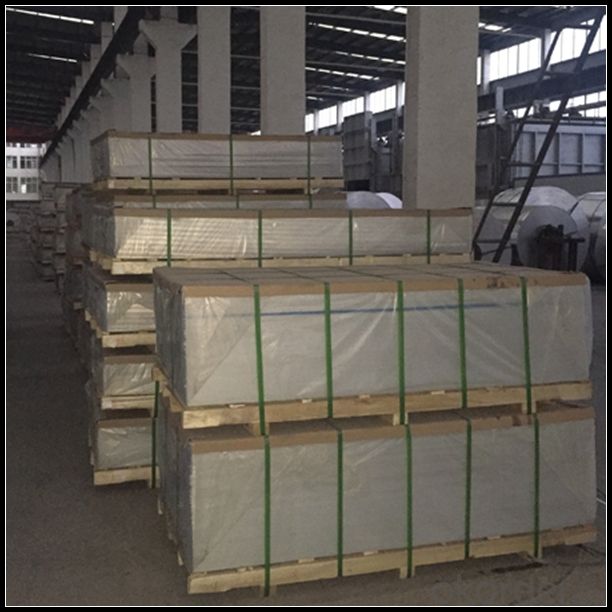

6. Package and shipping of Mill Finish Aluminium Sheet for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I want to use one aluminum bottle, rather than several plastic ones. And this may sound stupid, but will an aluminum water bottle be safe to put in the fridge?

- Yes, aluminum can go in the fridge. However, it has been linked to several brain disorders, to include Alzheimers. I recommend a stainless, or glass bottle for reuse. I have purchase drinks in a glass container, then reused the empty bottle for my water. Glass is a safe alternative to aluminum, and easy to keep clean! Continue to stay away from plastic, even if it is marked BPA free. Bisphenol-A (BPA) are common in plastics and continued studies declare BPA a health risk. My vote is for glass - it has stood the test of time!

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The surface roughness of an aluminum sheet affects its friction properties by increasing the surface area in contact with another object, leading to higher frictional forces. A rougher surface will have more irregularities and asperities, creating more points of contact and interlocking with the opposing surface. This increased contact area enhances the adhesion between the surfaces, resulting in higher friction. Conversely, a smoother surface with fewer irregularities will have reduced contact area and less adhesion, leading to lower friction.

- Q: Are aluminum sheets suitable for beverage cans?

- Indeed, beverage cans can be made from aluminum sheets. The beverage industry heavily relies on aluminum due to its exceptional qualities. This material is renowned for being lightweight and resistant to corrosion. Moreover, it acts as an effective shield against light, oxygen, and moisture, thereby ensuring the beverage's quality and freshness are preserved. In addition, aluminum is highly malleable, enabling the creation of cans with diverse shapes and sizes. Furthermore, it is worth noting that aluminum is recyclable, making it an environmentally conscious option. In summary, aluminum sheets perfectly fulfill the functional and sustainability criteria, rendering them the perfect choice for beverage cans.

- Q: What is the price range of aluminum sheets?

- The price range of aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range in price from $1 to $5 per square foot.

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The price of 101 aluminum sheets can vary depending on various factors such as market conditions, demand, and supply. However, generally speaking, 101 aluminum alloy is considered to be one of the most affordable options among aluminum alloys. It is often chosen for its relatively low cost and good overall performance. Compared to other aluminum alloys, especially high-strength alloys such as 7075 or 6061, the price of 101 aluminum sheets tends to be lower. This is because 101 aluminum is a relatively simple alloy with a lower composition of alloying elements, making it less expensive to produce. However, it is important to note that the price differentiation between aluminum alloys can vary depending on current market conditions and specific requirements. Factors such as the thickness, size, and quantity of sheets required can also impact the final price. Therefore, it is always recommended to check with suppliers or manufacturers to get the most accurate and up-to-date pricing information for 101 aluminum sheets compared to other aluminum alloys.

- Q: Hello, I dont really know anything about using a drill or cutting through metal or wood. the thing is I have a project in which I have to drill some holes in 0.04in aluminum. but I really dont know if can use regular drill bits used for drilling wood to drill the holes in my aluminum chassis. do I need to buy other drill bits for cutting metal or can I use the same ones Ive seen used for cutting wood? can I even use the same kind of drills, or do I NEED a huge bench drill with stepper bits?thanks

- Aluminum is softer than steel, so you could just use the ordinary bits that you use for wood, with a hand drill. For cleaner holes, you might want to put wood behind the aluminum as a backing. Also, if you squirt a drop of oil onto the drill area, that will help. If you're trying to drill a really large hole, it might be better to drill small ones, and enlarge with a round file.

- Q: What is the typical torsional strength of aluminum sheets?

- The typical torsional strength of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, and manufacturing process. However, in general, aluminum sheets have a good torsional strength compared to other materials. Aluminum alloys commonly used in sheet form, such as 6061-T6 and 5052-H32, have torsional strengths ranging from approximately 22,000 to 40,000 pounds per square inch (psi). These values represent the maximum amount of torque that can be applied to the aluminum sheet before it permanently deforms or fractures. It is important to note that torsional strength is just one aspect of the overall mechanical properties of aluminum sheets. Other factors like tensile strength, yield strength, and elongation also play significant roles in determining the suitability of aluminum sheets for specific applications. Therefore, when selecting aluminum sheets for a particular torsional application, it is essential to consider the specific requirements and consult with material suppliers or engineers to ensure the chosen aluminum sheet meets the desired torsional strength requirements.

- Q: what is the behaviour of Al2O3= aluminium oxide and SiO2= silicon dioxide when heated from room temperature to 1000 degree celcius?

- Aluminium oxide is a metal oxide and here shows it's basic properties. Silicon dioxide is a non metal oxide, so acidic Acid + base ---- salt so aluminium silicate is formed

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is a widely used material in the electronics industry due to its excellent conductivity, low weight, and high durability. It is commonly used for various applications such as housing for electronic components, heat sinks, and electrical connectors. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of electronic devices. Additionally, aluminum is a cost-effective material, making it an attractive choice for manufacturers in the electronics industry.

Send your message to us

Powder Coated Mill Finish Aluminum Sheets for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords