Aluminium Profile Curtain Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

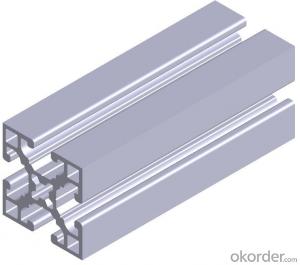

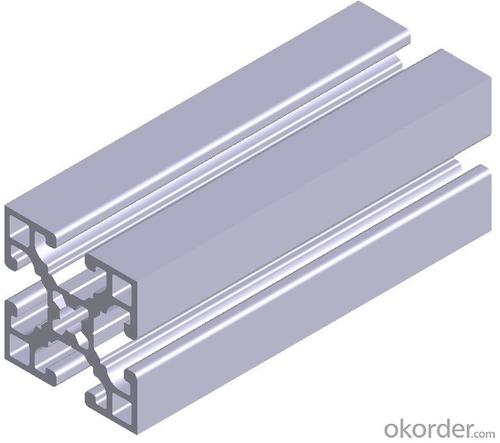

Structure of Aluminium Profile Curtain Wall Application Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Curtain Wall Application:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

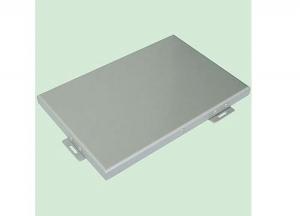

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminium Profile Curtain Wall Application:

Aluminium Profile Curtain Wall Application Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q: Are there any limitations on the length of aluminum profiles?

- The length of aluminum profiles is subject to limitations. These limitations arise from factors such as the manufacturing process, transportation constraints, and practicality. When it comes to manufacturing, aluminum profiles are typically either extruded or rolled. The length of these profiles is determined by the equipment and capabilities of the manufacturer. The extrusion presses and rolling mills have specific size limitations, which dictate the maximum length of aluminum profiles that can be produced. Transportation constraints also come into play when considering the length of aluminum profiles. Longer profiles may pose logistical challenges during transportation, primarily due to the size of trucks or shipping containers. Moreover, the risk of damage or deformation increases as the length of the profiles increases. Practicality is yet another factor that sets restrictions on the length of aluminum profiles. Longer profiles tend to be less rigid, making them more susceptible to sagging or bending under their own weight. As a result, they may not be suitable for certain applications. Additionally, handling and installing longer profiles may require specialized equipment and techniques. Despite these limitations, manufacturers can often produce aluminum profiles in various lengths to meet specific project requirements. However, it is crucial to consider these limitations and consult with the manufacturer to determine the feasibility of producing longer profiles if necessary.

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: Is it possible to recycle aluminum profiles repeatedly without a substantial loss in their quality or functionality?

- <p>Yes, aluminum profiles can be recycled multiple times without significant degradation in performance. Aluminum is highly recyclable, and the recycling process does not compromise its properties. In fact, recycled aluminum maintains the same strength, durability, and malleability as new aluminum. This makes it an environmentally friendly material, as it reduces the need for mining new aluminum and conserves resources.</p>

- Q: Is it possible to utilize aluminum profiles as part of the exterior cladding systems for commercial buildings?

- <p>Yes, aluminum profiles are commonly used for exterior cladding systems in commercial buildings. They offer several advantages such as durability, resistance to weather and corrosion, low maintenance, and a modern aesthetic. Aluminum's lightweight nature and strength make it an ideal material for cladding, and it can be easily shaped and joined to create a variety of designs. Additionally, aluminum profiles can be coated or anodized to provide color and further protection against the elements.</p>

- Q: Are aluminum profiles suitable for earthquake-resistant structures?

- Aluminum profiles can indeed be appropriate for structures that can withstand earthquakes. The lightweight and high-strength properties of aluminum offer numerous benefits when it comes to earthquake resistance. Firstly, the high strength-to-weight ratio makes it possible to construct lighter and more flexible buildings, which can better endure seismic forces. This is particularly important because it reduces the overall mass of the structure and lessens the inertia forces during an earthquake. Additionally, aluminum profiles possess outstanding corrosion resistance, ensuring the long-term durability and structural integrity of earthquake-resistant constructions. This is critical as corrosion can gradually weaken the structure, making it more susceptible to seismic events. Moreover, the malleability of aluminum allows for the creation of intricate and customized profiles, enabling architects and engineers to design structures that can effectively absorb and dissipate seismic energy. This flexibility is crucial in earthquake-resistant design because it allows the structure to deform and absorb the energy generated during an earthquake, thus minimizing the impact on the building and its occupants. Furthermore, aluminum is an environmentally friendly material as it is highly recyclable and requires significantly less energy to produce compared to other metals. Consequently, it is an eco-conscious choice for earthquake-resistant structures. Nevertheless, it is important to note that the suitability of aluminum profiles for earthquake-resistant structures depends on various factors, including specific design requirements, local seismic conditions, and the expertise of the engineers and architects involved. As a result, a thorough analysis and evaluation of the particular project requirements and conditions should be carried out before determining the appropriateness of aluminum profiles for earthquake-resistant structures.

- Q: This question asks whether aluminum profiles can be utilized for creating interior partitions and seeks reasons for their suitability.

- <p>Yes, aluminum profiles can be used for interior partitions. They are favored for several reasons: they are lightweight yet strong, offering durability and stability. Aluminum profiles are also resistant to corrosion, which makes them suitable for various environments. Their ease of installation and low maintenance requirements make them cost-effective. Additionally, they can be easily customized to fit various design needs, and their recyclability makes them an environmentally friendly choice.</p>

- Q: How are aluminum shapes made?

- 3, color (mainly about the oxidation process here first oxidation): extrusion Aluminum Alloy profiles well, its corrosion resistance is not strong, should be to increase the aluminum corrosion resistance, wear resistance and surface by anodic oxidation surface treatment of the appearance of the. The main process is as follows: (1) surface pretreatment: chemical or physical methods are used to clean the surface of the profile and expose the pure matrix to obtain a complete and compact artificial oxide film. The mirror or non light (Ya Guang) surface can also be obtained by mechanical means. (2) anodizing: the surface of the pre processed profiles, in a certain process conditions, the substrate surface anodic oxidation, resulting in a dense, porous, strong adsorption of AL203 film. (3) sealing: the pore space of the porous oxide film produced by anodic oxidation is closed, so that the oxidation film is anti pollution, and the corrosion resistance and wear resistance are enhanced. The film is colorless and transparent, with strong adsorption before sealing film, adsorption and deposition of metal salts in some membrane hole, can make the profile appearance character (silver) show many colors, except such as: black, bronze, golden color and stainless steel etc..

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

- Q: Are aluminum profiles suitable for balcony railings?

- Yes, aluminum profiles are suitable for balcony railings. Aluminum is a popular material choice for balcony railings due to its durability, strength, and low maintenance requirements. It is resistant to rust and corrosion, making it highly suitable for outdoor use. Additionally, aluminum profiles can be easily customized and shaped to fit any design preference or architectural style. They are lightweight, yet sturdy enough to provide the necessary support and safety for balcony railings. Aluminum railings are also available in a variety of finishes and colors, allowing for endless design possibilities. Overall, aluminum profiles are a reliable and stylish option for balcony railings.

Send your message to us

Aluminium Profile Curtain Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords