China Made Extruded Aluminum Profiles for Door Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Extruded Profile Aluminium Profile To Make Doors Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Extruded Profile Aluminium Profile To Make Doors :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

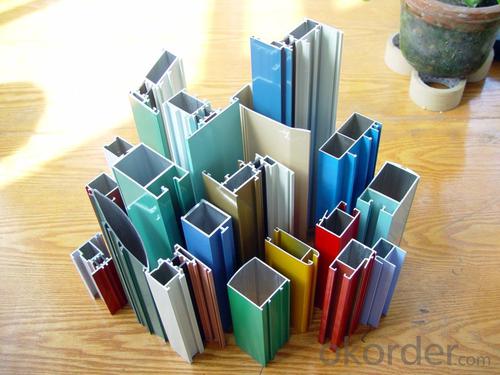

3.Extruded Profile Aluminium Profile To Make Doors Images:

4.Extruded Profile Aluminium Profile To Make DoorsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do aluminum profiles contribute to sustainable transportation solutions?

- Aluminum profiles play a significant role in promoting sustainable transportation solutions in several ways. Firstly, aluminum is a lightweight material, which means it can significantly reduce the weight of vehicles such as cars, buses, trains, and airplanes. This reduction in weight leads to improved fuel efficiency and lower greenhouse gas emissions. By using aluminum profiles in the manufacturing process, vehicles consume less energy and produce fewer pollutants, making them more environmentally friendly. Secondly, aluminum is a highly recyclable material. It can be easily recycled and reprocessed, allowing for the creation of new aluminum profiles without compromising their quality or performance. This recyclability aspect promotes a circular economy, reducing the need for extracting and refining raw materials continually. It also decreases the amount of waste generated and minimizes the environmental impact associated with the production and disposal of aluminum profiles. Furthermore, aluminum profiles are durable and corrosion-resistant, which extends the lifespan of vehicles. The increased durability reduces the frequency of maintenance and replacements, leading to lower resource consumption and waste generation. Consequently, it contributes to a more sustainable transportation system by reducing the overall environmental impact associated with vehicle manufacturing and operation. Additionally, aluminum profiles can be designed to enhance aerodynamics and improve the overall performance of vehicles. By reducing drag and optimizing airflow, aluminum profiles contribute to increased fuel efficiency and reduced energy consumption. This improved performance not only benefits the environment but also reduces operational costs for transportation companies and individuals. Overall, the use of aluminum profiles in transportation solutions has a positive impact on sustainability. It reduces vehicle weight, promotes recycling, extends lifespan, and enhances performance, all of which contribute to a more eco-friendly and efficient transportation system. By embracing aluminum profiles, the transportation industry can take significant strides towards achieving a more sustainable and greener future.

- Q: Can aluminum profiles be used in curtain wall systems?

- Yes, aluminum profiles can be commonly used in curtain wall systems. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for constructing curtain walls. Its versatility allows for various design options and structural support, making it a popular choice in the construction industry.

- Q: Are aluminum profiles suitable for use as interior finishing materials, specifically for flooring and wall panels?

- <p>Yes, aluminum profiles can be used for interior finishing materials such as flooring and wall panels. They are known for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be used in various designs and styles, making them a popular choice for modern interior design. They also offer the advantage of being recyclable and environmentally friendly.</p>

- Q: What are the different sealing options for aluminum profiles?

- There are several sealing options available for aluminum profiles, including anodizing, powder coating, liquid paint coating, and mechanical sealing. Anodizing is a popular choice, providing a durable and corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum. Powder coating involves applying a dry powder to the profile, which is then cured under heat to form a hard, smooth coating. Liquid paint coating can also be used, offering various colors and finishes, but may require more maintenance. Mechanical sealing involves using gaskets, tapes, or other sealing materials to create a tight seal between aluminum profiles. The choice of sealing option depends on the specific requirements of the application, such as desired aesthetics, durability, and environmental factors.

- Q: Can aluminum profiles be used in structural applications?

- Aluminum profiles, indeed, find utility in structural applications. The lightweight and resilient nature of aluminum, coupled with its commendable strength-to-weight ratio, renders it apt for a myriad of structural purposes. The construction industry frequently employs aluminum profiles for the construction of frames, beams, columns, and trusses in buildings and infrastructure. Additionally, these profiles witness usage in the creation of automotive components, aerospace structures, and marine applications. The benefits conferred by aluminum profiles, including corrosion resistance, ease of fabrication, and recyclability, further solidify their standing as a favored option for structural applications.

- Q: This question asks whether aluminum profiles can be utilized for creating interior partitions and seeks reasons for their suitability.

- <p>Yes, aluminum profiles can be used for interior partitions. They are favored for several reasons: they are lightweight yet strong, offering durability and stability. Aluminum profiles are also resistant to corrosion, which makes them suitable for various environments. Their ease of installation and low maintenance requirements make them cost-effective. Additionally, they can be easily customized to fit various design needs, and their recyclability makes them an environmentally friendly choice.</p>

- Q: Explain the positive environmental impacts of utilizing recycled aluminum in the construction industry.

- <p>Using recycled aluminum in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining new bauxite, the primary source of aluminum. This reduction in mining decreases habitat destruction, water pollution, and soil erosion. Additionally, recycling aluminum saves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to lower greenhouse gas emissions and air pollution. Moreover, the use of recycled aluminum reduces landfill waste, as less material ends up in landfills. Overall, it promotes a more sustainable and eco-friendly construction process.</p>

- Q: What are the load-bearing capacities of different aluminum profile shapes?

- The load-bearing capacities of different aluminum profile shapes vary depending on various factors such as the specific alloy of aluminum used, the size and dimensions of the profile, and the specific application or use case. Aluminum profiles, also known as extrusions, come in a wide range of shapes including I-beams, T-beams, square tubes, rectangular tubes, angles, and channels. Each profile shape has its own unique load-bearing capacity due to its structural design and cross-sectional properties. For example, I-beams are known for their high load-bearing capacity due to their shape, which allows for efficient weight distribution along the flanges. They are commonly used in structural applications where heavy loads need to be supported. T-beams, on the other hand, have a load-bearing capacity similar to I-beams but with a different cross-sectional shape. They are often used in applications where a flat surface is required on one side, such as in construction or automotive industries. Square and rectangular tubes are versatile profiles that are often used in building structures, frames, and support systems. Their load-bearing capacity depends on the wall thickness and size of the tube. Angles and channels, which have a L-shaped and U-shaped cross-section respectively, are commonly used in construction and manufacturing industries. Their load-bearing capacity depends on the size and dimensions of the profile. It is important to note that the load-bearing capacities of aluminum profiles are typically provided by the manufacturer and should be consulted for specific applications. Additionally, engineering calculations and considerations such as deflection, bending moments, and safety factors should be taken into account when determining the appropriate aluminum profile shape and size for a given load-bearing requirement.

- Q: This question asks for guidance on ensuring a safe and efficient installation process for aluminum profiles.

- <p>To ensure a safe and efficient installation process for aluminum profiles, follow these steps: Use appropriate safety gear such as gloves and goggles. Ensure the profiles are of high quality and fit for purpose. Plan the installation carefully, marking out the positions accurately. Use the correct tools for cutting and drilling, and ensure they are sharp and well-maintained. Install the profiles in a clean, dry environment to prevent damage. Follow the manufacturer's guidelines for assembly and use the correct fasteners. Regularly inspect the installation for any signs of wear or damage. By adhering to these practices, you can ensure a safe and efficient installation process.</p>

- Q: Can recycled aluminum be utilized in construction projects as an alternative to new, raw materials?

- <p>Yes, recycled aluminum can be used in building projects as an alternative to new raw materials. It is not only cost-effective but also environmentally friendly, reducing the energy required for production and the amount of waste sent to landfills. Recycled aluminum maintains the same strength and durability as new aluminum, making it suitable for various construction applications. However, it's important to ensure that the recycled aluminum meets the necessary quality standards and specifications for your project to avoid any structural or safety issues.</p>

Send your message to us

China Made Extruded Aluminum Profiles for Door Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords