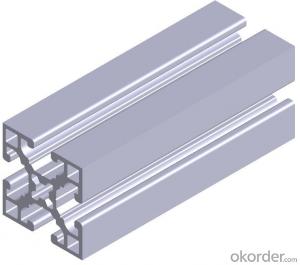

Aluminum T Slot Profiles Curtain Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can definitely be used for modular storage systems. Aluminum is a lightweight yet sturdy material that is commonly used in various industries for its durability and versatility. It is particularly well-suited for modular storage systems due to its ability to be easily cut, shaped, and joined together. Aluminum profiles provide a great solution for creating customized storage units that can be easily adjusted or expanded as needed. They can be used to build shelving systems, cabinets, drawers, and other storage components. The modular design allows for easy assembly and disassembly, making it convenient to rearrange or reconfigure the storage system whenever required. Furthermore, aluminum profiles offer excellent corrosion resistance, ensuring that the storage system will remain in good condition even in harsh environments. They are also available in a variety of finishes, allowing for customization to match the desired aesthetic or design requirements. Overall, aluminum profiles provide a cost-effective and durable solution for modular storage systems, offering flexibility, ease of use, and long-lasting performance.

- Q: This question asks about the effects of utilizing aluminum profiles in the construction industry on the environment.

- <p>The environmental impacts of using aluminum profiles in construction are multifaceted. On the positive side, aluminum is lightweight and strong, reducing the amount of material needed and potentially decreasing energy consumption in transportation. It is also recyclable, which can reduce waste and the need for raw material extraction. However, the production of aluminum requires significant energy, often from non-renewable sources, contributing to carbon emissions. Additionally, while recycling reduces environmental impact, it still consumes energy and can generate waste. The longevity and durability of aluminum can lead to less frequent replacement, reducing construction waste, but improper disposal can lead to pollution. Overall, the environmental impact depends on the balance between these factors and the specific practices of aluminum production and use in construction.</p>

- Q: Can aluminum profiles be used for window frames?

- Yes, aluminum profiles can be used for window frames. Aluminum is a popular material choice for window frames due to its durability, strength, and resistance to corrosion. It is lightweight, easy to shape, and can withstand various weather conditions, making it a suitable option for window frames. Additionally, aluminum profiles can be customized to fit different window sizes and designs, making them a versatile choice.

- Q: This question asks for methods to prevent rust formation on aluminum profiles during the periods of storage and transportation.

- <p>To prevent rust on aluminum profiles during storage and transportation, follow these guidelines: 1. Keep aluminum profiles dry and clean, avoiding contact with moisture or corrosive substances. 2. Store profiles in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging materials to shield profiles from physical damage and moisture. 4. Apply a protective coating or sealant to the aluminum surface if it's exposed to harsh environments. 5. Regularly inspect stored profiles for signs of corrosion and address any issues promptly. By adhering to these practices, you can minimize the risk of rust formation on aluminum profiles during storage and transportation.</p>

- Q: Can aluminum profiles be recycled indefinitely?

- Yes, aluminum profiles can be recycled indefinitely. Unlike other materials, aluminum does not degrade during the recycling process. It can be melted down and reshaped into new profiles without losing its inherent properties. This essentially means that aluminum profiles have a never-ending life cycle. Recycling aluminum requires significantly less energy and resources compared to producing new aluminum, making it an environmentally sustainable option. Moreover, the recycling process can be repeated countless times without any loss in quality, making aluminum one of the most recycled materials in the world.

- Q: Can aluminum profiles be used for creating lighting fixtures?

- Indeed, lighting fixtures can be fashioned using aluminum profiles. The lightweight quality, durability, and resistance to corrosion render aluminum a favored material for such fixtures. Moreover, its malleability and feasibility for machining make it appropriate for crafting diverse designs and styles of lighting fixtures. Further, aluminum profiles can undergo powder coating or anodization to enrich their visual allure and furnish supplementary safeguard against deterioration. The adaptability and aesthetic charm of aluminum designate it as an optimal selection for producing lighting fixtures across an extensive array of environments, encompassing residential, commercial, and industrial settings.

- Q: This question seeks to understand the methods used to prevent rust and corrosion on aluminum profiles.

- <p>To prevent aluminum profiles from rusting and corroding, several methods can be employed: 1) Anodizing: This process creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion. 2) Powder Coating: Applying a durable powder coating can protect the aluminum from moisture and other corrosive elements. 3) Regular Cleaning: Regularly cleaning the aluminum profiles can remove dirt and debris that may lead to corrosion. 4) Protective Films: Applying protective films or tapes can shield the aluminum from environmental factors that cause corrosion. 5) Proper Storage: Storing aluminum profiles in a dry, well-ventilated area can prevent moisture accumulation, which is a leading cause of rust. 6) Use of Corrosion Inhibitors: Applying corrosion inhibitors can slow down or prevent the chemical reactions that lead to corrosion. By implementing these measures, the lifespan and integrity of aluminum profiles can be significantly improved.</p>

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- There seems to be an aluminum profile market over the West Bridge

- Q: This question asks for guidance on selecting suitable aluminum profiles for a construction project.

- <p>To choose the right aluminum profiles for your building project, consider the following: 1. Load-bearing capacity: Select profiles that can withstand the weight and stress of your structure. 2. Application: Choose profiles suitable for the specific application, such as window frames, curtain walls, or support beams. 3. Aesthetics: Opt for profiles that match your project's design and architectural style. 4. Durability: Look for high-quality aluminum with good corrosion resistance and weather resistance. 5. Cost: Compare prices and choose profiles that offer the best value for money. 6. Supplier reputation: Work with reputable suppliers known for quality products and reliable service. Consult with engineers or architects to ensure you select the most appropriate profiles for your project's needs.</p>

- Q: What are the different surface embossing options for aluminum profiles?

- Some of the different surface embossing options for aluminum profiles include brushed, mirrored, textured, patterned, and perforated finishes.

Send your message to us

Aluminum T Slot Profiles Curtain Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords