All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Aluminum StripsView More

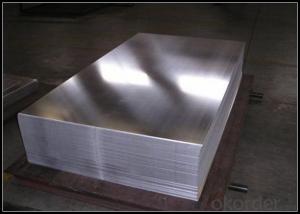

Aluminum SheetsView More

Aluminum CoilsView More

Aluminum FoilsView More

Aluminum ProfilesView More

Q & A

How is aluminum used in the automotive industry to improve fuel efficiency?

Aluminum is used in the automotive industry to improve fuel efficiency primarily due to its lightweight nature. By replacing heavier components, such as engine blocks and body panels, with aluminum alternatives, vehicles become lighter, resulting in reduced fuel consumption. Additionally, aluminum's excellent heat dissipation properties allow for the production of more efficient engines and exhaust systems, further enhancing fuel efficiency.

What is the difference between system window aluminum materials?

The difference between system window aluminum materials lies in their composition, thickness, strength, and design. Various alloys and grades of aluminum can be used, each offering different levels of durability, corrosion resistance, and thermal performance. Additionally, the thickness of the aluminum frames can vary, affecting the overall strength and rigidity of the window system. Furthermore, the design and extrusion profile of the aluminum frames can vary, allowing for different aesthetic options and functionality features. Ultimately, the choice of system window aluminum material depends on factors such as budget, desired performance, and aesthetic preferences.

What considerations are there for selecting the thickness of aluminum materials?

When selecting the thickness of aluminum materials, several considerations come into play. Firstly, the intended application and structural requirements are crucial. Thicker aluminum materials provide greater strength and durability, making them suitable for heavy-duty applications. Secondly, the weight and cost factors need to be evaluated. Thinner aluminum materials are lighter and more cost-effective, making them preferable for applications where weight reduction and lower expenses are desired. Additionally, the manufacturing process and available equipment should be considered, as some fabrication methods may have limitations on the thickness of aluminum that can be effectively used. Finally, environmental factors, such as exposure to corrosion or extreme temperatures, might require specific thicknesses to ensure proper performance and longevity. Overall, the selection of aluminum thickness should be based on a careful evaluation of these factors to meet the specific requirements of the application.

Wholesale Aluminum from supplier in Cuba

Whether you require aluminum sheets, coils, profiles, or other customized products, we can fulfill your specific requirements. Our team of experienced professionals is dedicated to delivering high-quality products that meet international standards.

In addition to our wide range of aluminum products, we also provide value-added services such as cutting, bending, and surface treatment. Our technical support team is always ready to assist you with any inquiries or challenges you may encounter during the procurement process.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring that we can source the highest quality materials at competitive prices. Our strong relationships with local partners in Cuba enable us to provide efficient logistics and timely delivery to your project site.

We understand the unique challenges and regulations associated with doing business in Cuba. Our years of experience in the Cuban market have allowed us to navigate these complexities and build strong relationships with local authorities and stakeholders. This knowledge and insight are invaluable in ensuring a smooth and successful procurement experience for our customers.

At our company, customer satisfaction is our top priority. We are committed to providing personalized service and support to ensure that your aluminum procurement needs are met efficiently and effectively. Contact us today to discuss your requirements and let us be your trusted partner for aluminum products in Cuba.

In addition to our wide range of aluminum products, we also provide value-added services such as cutting, bending, and surface treatment. Our technical support team is always ready to assist you with any inquiries or challenges you may encounter during the procurement process.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring that we can source the highest quality materials at competitive prices. Our strong relationships with local partners in Cuba enable us to provide efficient logistics and timely delivery to your project site.

We understand the unique challenges and regulations associated with doing business in Cuba. Our years of experience in the Cuban market have allowed us to navigate these complexities and build strong relationships with local authorities and stakeholders. This knowledge and insight are invaluable in ensuring a smooth and successful procurement experience for our customers.

At our company, customer satisfaction is our top priority. We are committed to providing personalized service and support to ensure that your aluminum procurement needs are met efficiently and effectively. Contact us today to discuss your requirements and let us be your trusted partner for aluminum products in Cuba.