All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the considerations when using hollow steel tubes in earthquake-resistant bridges?

When using hollow steel tubes in earthquake-resistant bridges, there are several important considerations to take into account.

Firstly, the design of the bridge should consider the seismic forces that the structure will be subjected to. Hollow steel tubes can provide flexibility and ductility, allowing them to absorb and dissipate energy during an earthquake. Therefore, the dimensions, wall thickness, and material properties of the tubes should be carefully selected to ensure they can withstand the anticipated seismic forces.

Secondly, the connections between the hollow steel tubes and other structural elements should be carefully designed and detailed. These connections need to be strong enough to resist the forces generated during an earthquake, while also allowing for some flexibility and movement of the tubes. Proper connection design is crucial to ensure the overall stability and safety of the bridge.

Thirdly, the construction and quality control processes should be closely monitored. Fabrication and welding of hollow steel tubes require strict adherence to industry standards and codes to ensure their integrity. Regular inspections and testing should be conducted to verify the quality of the tubes and their connections.

Lastly, ongoing maintenance and inspection of the bridge are essential to ensure its long-term durability and safety. Routine inspections should be performed to identify any potential issues or damage to the hollow steel tubes, and appropriate repairs or reinforcement should be carried out promptly.

Overall, the considerations when using hollow steel tubes in earthquake-resistant bridges revolve around the design, connections, construction, and maintenance of the structure. By addressing these factors, engineers can enhance the seismic performance and resilience of the bridge, ensuring its safe operation during and after an earthquake.

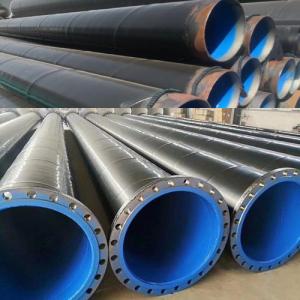

Are hollow steel tubes available in different shapes?

Yes, hollow steel tubes are available in various shapes such as round, square, rectangular, and oval, among others.

Can hollow steel tubes be used for water transportation?

Yes, hollow steel tubes can be used for water transportation. They are commonly used in the construction of pipelines and water supply systems due to their durability, ability to withstand high pressure, and resistance to corrosion.

Can hollow steel tubes be used for modular construction?

Yes, hollow steel tubes can be used for modular construction. They are commonly used as structural elements in modular construction due to their strength, durability, and versatility. The hollow design allows for easy integration of electrical and plumbing systems, making them ideal for various types of modular building projects.

How do hollow steel tubes perform in extreme temperature variations?

Hollow steel tubes have good performance in extreme temperature variations due to their high thermal conductivity and low thermal expansion coefficient. These properties allow the tubes to efficiently transfer heat and minimize any potential deformation or structural damage caused by temperature changes.

Wholesale Hollow Steel Tubes from supplier in Cuba

Our team of experts is dedicated to understanding your specific requirements and providing tailored solutions to meet your needs. Whether you are looking for Hollow Steel Tubes for construction, infrastructure, or any other industry, we have the knowledge and resources to assist you.

In addition to offering sales and quotes, we also provide technical support to ensure that you have the necessary information and guidance to make informed decisions. Our technical team is well-versed in the properties and applications of Hollow Steel Tubes and can help you select the right product for your project.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, ensuring that we can offer a wide range of Hollow Steel Tubes products. We work closely with trusted suppliers to ensure the quality and reliability of our products.

Furthermore, our experience in operating in Cuba gives us a deep understanding of the local market dynamics, regulations, and challenges. We can provide valuable insights and expertise to help you navigate the procurement process and optimize your projects.

At our company, we prioritize customer satisfaction and strive to provide exceptional service. We are committed to delivering high-quality products, competitive prices, and reliable support to our customers in Cuba.

Contact us today to discuss your Hollow Steel Tubes requirements and let us assist you in achieving your project goals.

In addition to offering sales and quotes, we also provide technical support to ensure that you have the necessary information and guidance to make informed decisions. Our technical team is well-versed in the properties and applications of Hollow Steel Tubes and can help you select the right product for your project.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, ensuring that we can offer a wide range of Hollow Steel Tubes products. We work closely with trusted suppliers to ensure the quality and reliability of our products.

Furthermore, our experience in operating in Cuba gives us a deep understanding of the local market dynamics, regulations, and challenges. We can provide valuable insights and expertise to help you navigate the procurement process and optimize your projects.

At our company, we prioritize customer satisfaction and strive to provide exceptional service. We are committed to delivering high-quality products, competitive prices, and reliable support to our customers in Cuba.

Contact us today to discuss your Hollow Steel Tubes requirements and let us assist you in achieving your project goals.