All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

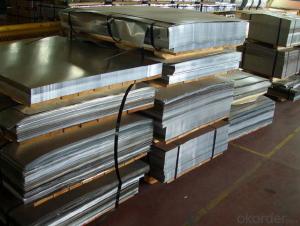

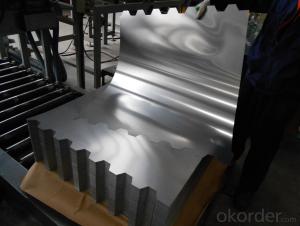

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the main international standards for electrolytic tinplate coil?

The main international standards for electrolytic tinplate coil include ISO 11949:2015 (which specifies general requirements and test methods), ASTM A623/A623M-12 (which covers tinplate thickness and tin coating weight specifications), and JIS G 3303:2019 (which outlines the requirements for tinplate dimensions, mechanical properties, and chemical composition).

How does electrolytic tinplate coil perform in terms of scratch and abrasion resistance?

Electrolytic tinplate coil exhibits excellent scratch and abrasion resistance due to its durable and protective tin coating. This coating acts as a barrier against external forces, preventing scratches and abrasions from occurring on the surface of the tinplate coil.

How does the tin coating on electrolytic tinplate coil affect its resistance to tin whiskers?

The tin coating on electrolytic tinplate coil helps to reduce the formation and growth of tin whiskers, thereby increasing its resistance to tin whiskers.

What are the benefits of using electrolytic tinplate coil in the packaging of dairy products?

Using electrolytic tinplate coil in the packaging of dairy products offers several benefits. Firstly, it provides a strong and durable barrier against external factors such as light, air, moisture, and odors, which helps in preserving the freshness and quality of the dairy products. Secondly, tinplate is a food-safe material that does not react with the dairy products, ensuring their safety and preventing any contamination. Additionally, tinplate coil packaging is easily customizable, allowing for attractive and eye-catching designs that can help in promoting the dairy products and enhancing their shelf appeal. Lastly, tinplate is a highly recyclable material, making it an environmentally friendly choice for packaging, aligning with the sustainability goals of many dairy product manufacturers.

What is the shelf life of electrolytic tinplate coil?

The shelf life of electrolytic tinplate coil can vary depending on various factors such as the storage conditions, handling, and manufacturing process. However, on average, it is safe to say that the shelf life of electrolytic tinplate coil can range from several months to a few years. It is crucial to store the coil in a dry and well-ventilated area, away from direct sunlight and extreme temperatures, to maximize its shelf life. Regular inspection and adherence to manufacturer guidelines can help ensure the coil's quality and extend its shelf life.

Wholesale Electrolytic Tinplate Coil from supplier in Cuba

Whether you are looking for high-quality Electrolytic Tinplate Coils or require assistance with pricing and technical support, our team is dedicated to meeting your specific needs. As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide comprehensive procurement services for Electrolytic Tinplate Coils in Cuba.

Our extensive range of products ensures that we can cater to various requirements and specifications. We understand the unique demands of the Cuban market and have developed valuable expertise over the years. This enables us to offer insights and guidance based on our experience, ensuring that you receive the best solutions for your projects.

In addition to supplying Electrolytic Tinplate Coils, we also provide sales support to ensure a smooth and efficient purchasing process. Our team is readily available to answer any questions or concerns you may have and can assist with pricing negotiations to ensure competitive rates.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. From initial product selection to installation and maintenance, we are committed to providing the necessary expertise and guidance to ensure successful outcomes.

Partnering with us means gaining access to top-quality Electrolytic Tinplate Coils, along with exceptional sales, pricing, and technical support. We are dedicated to delivering customer satisfaction and building long-term relationships with our clients in Cuba. Contact us today to discuss your requirements and learn more about how we can support your projects.

Our extensive range of products ensures that we can cater to various requirements and specifications. We understand the unique demands of the Cuban market and have developed valuable expertise over the years. This enables us to offer insights and guidance based on our experience, ensuring that you receive the best solutions for your projects.

In addition to supplying Electrolytic Tinplate Coils, we also provide sales support to ensure a smooth and efficient purchasing process. Our team is readily available to answer any questions or concerns you may have and can assist with pricing negotiations to ensure competitive rates.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. From initial product selection to installation and maintenance, we are committed to providing the necessary expertise and guidance to ensure successful outcomes.

Partnering with us means gaining access to top-quality Electrolytic Tinplate Coils, along with exceptional sales, pricing, and technical support. We are dedicated to delivering customer satisfaction and building long-term relationships with our clients in Cuba. Contact us today to discuss your requirements and learn more about how we can support your projects.