All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

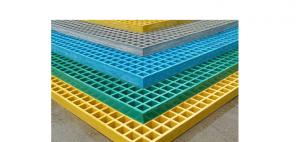

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What materials are used in FRP pultrusion profiles?

Fiber Reinforced Polymer (FRP) pultrusion profiles typically use a combination of reinforcing fibers, such as fiberglass or carbon fiber, and a polymer resin matrix, such as polyester, vinyl ester, or epoxy resin.

How does FRP pultrusion differ from other manufacturing processes?

FRP pultrusion differs from other manufacturing processes in several ways. Firstly, it is a continuous process where fibers are pulled through a resin bath and then shaped into a desired profile using a heated die. This results in a consistent and uniform product with high strength-to-weight ratio.

Unlike other processes such as extrusion or injection molding, pultrusion allows for the production of long and continuous profiles, eliminating the need for joining multiple sections together. This not only saves time and labor but also improves the structural integrity of the final product.

Additionally, FRP pultrusion offers design flexibility as various reinforcements and resin systems can be used to tailor the mechanical properties of the composite material. This makes it suitable for a wide range of applications where specific strength, corrosion resistance, or electrical insulation properties are required.

Furthermore, pultruded FRP profiles have excellent dimensional stability, low thermal expansion, and resistance to chemicals, UV radiation, and extreme temperatures. This makes them highly durable and suitable for outdoor or harsh environments.

Overall, FRP pultrusion stands out due to its continuous process, high strength-to-weight ratio, design flexibility, and excellent durability, making it a preferred choice in various industries such as construction, automotive, aerospace, and infrastructure.

Are FRP pultrusion profiles resistant to buckling?

Yes, FRP pultrusion profiles are generally resistant to buckling due to their high strength-to-weight ratio and structural integrity. The continuous fiber reinforcement in the pultruded profiles provides excellent stiffness and load-bearing capabilities, making them less prone to buckling under compressive loads compared to other materials. However, the specific design and dimensions of the profiles, as well as the applied loads, should be taken into consideration to ensure optimal performance and prevent buckling.

Wholesale FRP Pultrusion Profiles from supplier in Cuba

Our dedicated team of professionals is committed to providing you with exceptional customer service. We understand the unique challenges and requirements of the Cuban market and will work closely with you to ensure that your needs are met.

In addition to supplying high-quality FRP Pultrusion Profiles, we also offer a range of services to support your projects. Our technical support team can provide guidance on product selection, installation, and maintenance. We can also assist with project planning, offering valuable advice and expertise to help you achieve your goals.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to offer competitive pricing and reliable delivery, ensuring that you receive your FRP Pultrusion Profiles on time and within budget.

At our company, we believe in building long-term relationships with our clients. We strive to exceed your expectations and become your trusted partner for all your FRP Pultrusion Profiles needs in Cuba. Contact us today to learn more about our products and services and how we can assist you with your procurement needs.

In addition to supplying high-quality FRP Pultrusion Profiles, we also offer a range of services to support your projects. Our technical support team can provide guidance on product selection, installation, and maintenance. We can also assist with project planning, offering valuable advice and expertise to help you achieve your goals.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to offer competitive pricing and reliable delivery, ensuring that you receive your FRP Pultrusion Profiles on time and within budget.

At our company, we believe in building long-term relationships with our clients. We strive to exceed your expectations and become your trusted partner for all your FRP Pultrusion Profiles needs in Cuba. Contact us today to learn more about our products and services and how we can assist you with your procurement needs.