All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you calculate the yield strength of aluminum coils?

To calculate the yield strength of aluminum coils, you typically perform a tensile test. This involves applying a gradually increasing load to the coil until it reaches a point where it undergoes permanent deformation or elongation. The yield strength is then determined by dividing the maximum load applied during the test by the original cross-sectional area of the coil.

How do you prevent thermal distortion in aluminum coils during processing?

Thermal distortion in aluminum coils during processing can be prevented by implementing proper cooling techniques such as controlled cooling rates, uniform air circulation, and using cooling fixtures. Additionally, minimizing thermal gradients, avoiding sudden temperature changes, and maintaining optimum processing parameters can also help prevent thermal distortion in aluminum coils.

How is the gauge of aluminum coils measured?

The gauge of aluminum coils is typically measured using a thickness gauge, which determines the thickness of the aluminum sheet or coil.

What is the cost difference between anodized and non-anodized aluminum coils?

The cost difference between anodized and non-anodized aluminum coils can vary depending on factors such as the size, quantity, and specific application. However, generally speaking, anodized aluminum coils tend to be more expensive than non-anodized ones due to the additional manufacturing process involved in anodizing, which enhances the durability, corrosion resistance, and color options of the metal.

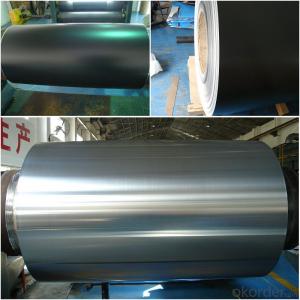

Wholesale Aluminum Coils from supplier in Cuba

Whether you require Aluminum Coils for construction, manufacturing, or any other industry, our team of experts can assist you in finding the right product to meet your specific needs. We understand the unique challenges and regulations of the Cuban market and can help navigate through them to ensure a seamless procurement process.

In addition to our wide range of Aluminum Coils, we also provide exceptional customer service and technical support. Our dedicated team is committed to assisting you throughout the entire purchasing journey, from product selection to delivery. We strive to build long-lasting relationships with our customers by offering personalized solutions and ensuring their satisfaction.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to provide competitive pricing and reliable supply chain management for Aluminum Coils in Cuba. Our strong network of suppliers and logistics partners ensure timely delivery and efficient operations.

Choosing us as your supplier for Aluminum Coils in Cuba means benefitting from our extensive industry knowledge and expertise. We stay updated with the latest market trends, regulations, and technological advancements, enabling us to provide valuable insights and recommendations to optimize your projects.

Whether you need Aluminum Coils for construction projects, manufacturing processes, or any other applications, we are here to meet your requirements. Contact us today to discuss your needs and discover how our comprehensive procurement solutions can enhance the success of your projects in Cuba.

In addition to our wide range of Aluminum Coils, we also provide exceptional customer service and technical support. Our dedicated team is committed to assisting you throughout the entire purchasing journey, from product selection to delivery. We strive to build long-lasting relationships with our customers by offering personalized solutions and ensuring their satisfaction.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to provide competitive pricing and reliable supply chain management for Aluminum Coils in Cuba. Our strong network of suppliers and logistics partners ensure timely delivery and efficient operations.

Choosing us as your supplier for Aluminum Coils in Cuba means benefitting from our extensive industry knowledge and expertise. We stay updated with the latest market trends, regulations, and technological advancements, enabling us to provide valuable insights and recommendations to optimize your projects.

Whether you need Aluminum Coils for construction projects, manufacturing processes, or any other applications, we are here to meet your requirements. Contact us today to discuss your needs and discover how our comprehensive procurement solutions can enhance the success of your projects in Cuba.