All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

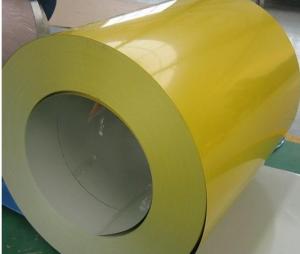

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil cleanliness ensured during the production of medical equipment?

Coil cleanliness is ensured during the production of medical equipment through various measures. Firstly, manufacturers implement strict quality control procedures that include regular inspections and cleaning of coils at different stages of production. Specialized cleaning agents and techniques are used to remove any dust, dirt, or contaminants that may accumulate on the coils. Additionally, cleanroom environments are maintained to minimize airborne particles and ensure a clean manufacturing environment. Moreover, manufacturers may also utilize automated cleaning processes, such as ultrasonic cleaning or high-pressure water jets, to effectively clean the coils without causing damage. These combined efforts ensure that the coils used in medical equipment are kept clean and free from any potential impurities that could affect their performance or pose a risk to patients.

What are the advancements in coil slitting technology for precision cutting in the construction sector?

In recent years, there have been significant advancements in coil slitting technology for precision cutting in the construction sector. These advancements include the development of high-speed and automated coil slitting machines that can handle a wide range of materials with greater accuracy and efficiency. Additionally, there have been improvements in the software and control systems used in these machines, allowing for more precise and customizable cuts. Furthermore, the integration of laser cutting technology has revolutionized the process by providing cleaner and more precise cuts, reducing material waste, and increasing overall productivity. These advancements in coil slitting technology have greatly enhanced the construction sector's ability to produce high-quality and accurately sized materials, leading to more efficient and cost-effective construction projects.

What are the quality control measures in steel coil packaging?

Quality control measures in steel coil packaging typically include thorough inspection of the coils for any defects or damages, ensuring proper alignment and stacking of the coils, use of protective materials or coatings to prevent corrosion or scratches, and strict adherence to packaging standards and guidelines set by the industry. Additionally, regular monitoring and testing of the packaging materials and techniques may be conducted to ensure the highest quality standards are maintained.

Wholesale Steel Coils from supplier in Rwanda

We are a Steel Coils supplier serving the Rwanda, mainly engaged in the sale, quotation, and technical support services of various Steel Coils products in the Rwanda region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Coils procurement services in the Rwanda. Not only do we have a wide range of Steel Coils products, but after years of market development in the Rwanda, we can also provide valuable experience for your projects.