All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

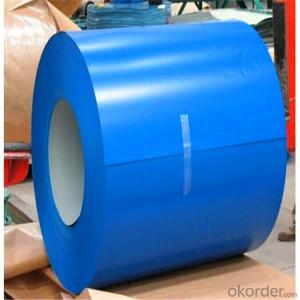

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you select the right special steel grade for a specific application?

To select the right special steel grade for a specific application, several factors need to be considered. Firstly, the requirements of the application must be thoroughly understood, including the desired mechanical properties, corrosion resistance, and temperature resistance. Secondly, the specific conditions in which the steel will be used, such as the environment and operating conditions, must be analyzed. Thirdly, it is crucial to consult with experts and utilize available resources such as technical databases, material selection guides, and industry standards. By carefully evaluating these factors, one can make an informed decision and select the appropriate special steel grade for the specific application.

Describe the applications of silicon steel in transformers and magnetic cores.

Silicon steel, also known as electrical steel or transformer steel, finds extensive applications in transformers and magnetic cores. This type of steel is specifically designed to have low magnetic losses, making it ideal for use in electrical devices. The main applications of silicon steel in transformers and magnetic cores include reducing energy losses, improving efficiency, and enhancing overall performance. It helps to concentrate and direct magnetic fields, thereby increasing the magnetic flux density in the core. This leads to reduced energy dissipation in the form of heat, resulting in improved energy efficiency. Silicon steel also helps to reduce the core's hysteresis and eddy current losses, further enhancing the transformer's efficiency. Overall, silicon steel plays a crucial role in optimizing the performance and energy efficiency of transformers and magnetic cores.

Can you explain the role of heat treatment in modifying special steel properties?

Heat treatment plays a crucial role in modifying the properties of special steels. By subjecting the steel to controlled heating and cooling processes, it can enhance its mechanical properties such as hardness, strength, toughness, and ductility. Heat treatment techniques like annealing, quenching, tempering, and normalizing can alter the microstructure and refine the grain size of the steel, resulting in improved performance and desired characteristics. This process also helps in relieving internal stresses and increasing the steel's resistance to wear, corrosion, and fatigue, making it suitable for various industrial applications.

Wholesale Special Steel from supplier in Rwanda

We are a Special Steel supplier serving the Rwanda, mainly engaged in the sale, quotation, and technical support services of various Special Steel products in the Rwanda region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Special Steel procurement services in the Rwanda. Not only do we have a wide range of Special Steel products, but after years of market development in the Rwanda, we can also provide valuable experience for your projects.