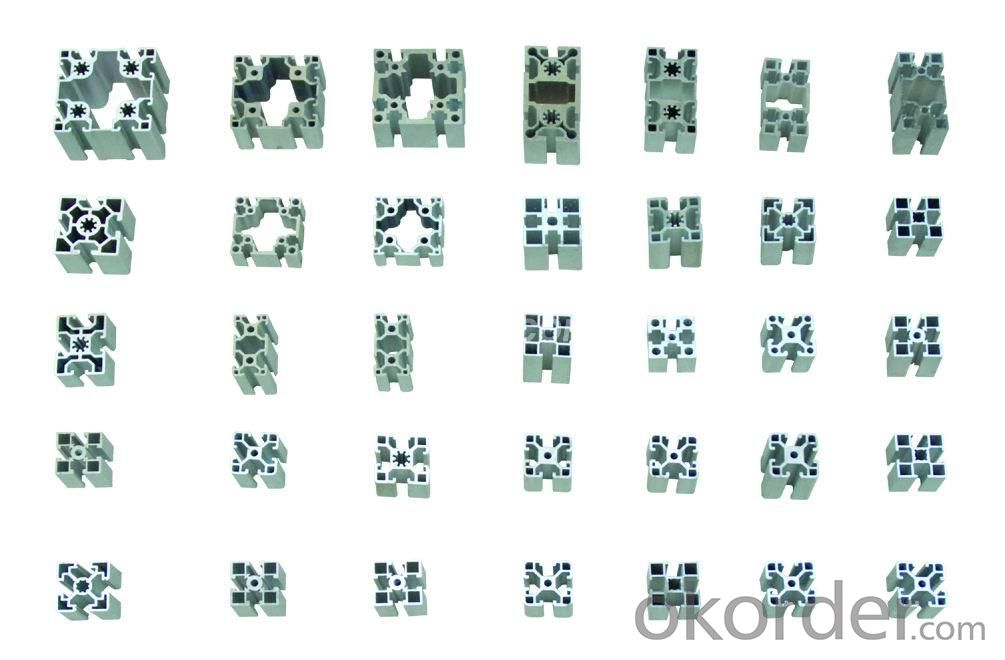

T Slot Aluminum Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight,ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector(as much as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengthsranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawnand extruded.

Advantage:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: Are aluminum profiles suitable for use as exterior wall materials?

- <p>Yes, aluminum profiles can be used for exterior walls. They are known for their durability, resistance to weathering, and low maintenance requirements. Aluminum is lightweight, strong, and can be easily shaped into various designs. It also has excellent resistance to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be powder coated or anodized for enhanced protection and aesthetic appeal, allowing them to blend well with different architectural styles.</p>

- Q: This question asks whether aluminum profiles are susceptible to damage from moisture and corrosion.

- <p>Aluminum profiles are generally resistant to moisture and corrosion due to their natural protective oxide layer. However, this resistance can be compromised in certain conditions. For instance, in highly corrosive environments or when exposed to aggressive chemicals, the protective layer may not be sufficient. Additionally, if the aluminum is not properly sealed or coated, it can still be affected by moisture over time. It's important to maintain the integrity of the protective layer and consider the specific environment when using aluminum profiles to ensure their longevity and resistance to corrosion.</p>

- Q: Can aluminum profiles be used in the production of laboratory equipment?

- Laboratory equipment manufacturing can utilize aluminum profiles effectively. Aluminum, being a versatile material, finds application in multiple industries, including the production of laboratory equipment. Aluminum profiles provide numerous benefits in this regard. To begin with, aluminum possesses a combination of lightweight and strength, making it an ideal choice for constructing portable or frequently movable equipment within laboratories. Its lightweight nature reduces the strain on laboratory personnel while handling and transporting the equipment. Moreover, aluminum profiles offer easy shaping and molding capabilities, enabling the customization of laboratory equipment to meet specific requirements. This design flexibility allows for the creation of equipment with complex shapes and structures, ensuring optimal functionality and efficiency. In addition, aluminum exhibits excellent corrosion resistance, a crucial property in laboratory settings where exposure to chemicals and liquids is common. This corrosion resistance extends the lifespan of the equipment and maintains its good condition even after prolonged use. Furthermore, aluminum profiles can be anodized or coated to provide additional protection against wear, scratches, and other forms of damage. This enhances the durability and facilitates easier cleaning, ensuring the maintenance of required hygiene standards in laboratories. Lastly, aluminum possesses high conductivity, making it suitable for applications that require heat transfer or electrical conductivity. This property proves advantageous for laboratory equipment, such as heating plates, heat sinks, or electrical circuit components. In conclusion, aluminum profiles are indeed suitable for the production of laboratory equipment. Their lightweight, malleable, corrosion-resistant, and conductive properties make them an excellent choice for manufacturing various types of laboratory equipment, guaranteeing durability, functionality, and ease of use.

- Q: Can aluminum profiles be used in the construction of exhibition booths?

- Indeed, exhibition booths can be constructed using aluminum profiles. These profiles possess the desirable qualities of being lightweight, durable, and versatile, making them the perfect option for building modular exhibition booths. The assembly and disassembly of these profiles are effortless, facilitating convenient transportation and modification of the booth's arrangement. Moreover, aluminum profiles present a sleek and contemporary appearance, enhancing the professional and visually captivating presentation for exhibitors. They can be utilized to construct frames, partitions, shelving, signage, and numerous other essential components necessary for exhibition booths. In summary, aluminum profiles provide an economical and effective resolution for constructing exhibition booths.

- Q: What are the advantages of using aluminum profiles in the aviation industry?

- There are several advantages of using aluminum profiles in the aviation industry. Firstly, aluminum is lightweight, which helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and lower operating costs. Secondly, aluminum profiles offer excellent strength-to-weight ratio, providing structural integrity and durability to withstand the demanding conditions of aviation. Thirdly, aluminum is corrosion-resistant, making it ideal for withstanding the effects of moisture and other environmental elements. Additionally, aluminum profiles are easy to fabricate, allowing for efficient manufacturing processes and quicker turnaround times.

- Q: Are aluminum profiles suitable for architectural design that demands a distinctive visual appeal?

- <p>Yes, aluminum profiles can be effectively utilized in architectural design to achieve a unique aesthetic look. They offer versatility in terms of shape and size, allowing for the creation of distinctive designs. Their lightweight nature and high strength make them ideal for various architectural applications. Additionally, aluminum profiles can be easily finished or coated to match specific design requirements, enhancing their visual appeal. Their durability and resistance to corrosion also make them a sustainable choice for long-lasting architectural projects.</p>

- Q: What are the different types of fasteners used for aluminum profiles?

- Some of the different types of fasteners used for aluminum profiles include screws, bolts, nuts, rivets, and T-slot nuts. These fasteners are designed to securely join aluminum profiles together for various applications in industries such as construction, manufacturing, and automotive.

- Q: How do aluminum profiles perform in thermal insulation applications?

- Aluminum profiles generally have poor thermal insulation properties compared to other materials. However, their performance can be enhanced by including thermal breaks or using aluminum profiles with built-in insulation, such as polyamide strips. Additionally, the use of double or triple glazing in combination with aluminum profiles can further improve thermal insulation in applications such as windows and doors.

- Q: This question asks for a list of various aluminum profiles that are specifically designed or used for roofing systems in regions with cold climates.

- <p>In cold climates, aluminum profiles for roofing systems are selected for their durability, strength, and resistance to harsh weather conditions. Common types include: 1. Standing Seam Profiles: These are popular for their weather-tightness and resistance to snow and ice. 2. Trapezoidal Profiles: Known for their strength and ability to handle heavy snow loads. 3. Box Rib Profiles: These provide excellent structural integrity and are suitable for areas with high wind uplift. 4. Snap-Lock Profiles: Easy to install and offer good resistance to snow and ice. 5. Corrugated Profiles: Provide a traditional look while being cost-effective and offering good drainage. 6. Panel Rib Profiles: These are designed for long spans and can withstand heavy snowfall. Each profile has specific applications and advantages, and the choice depends on the specific roofing requirements and local climate conditions.</p>

- Q: This question asks about the impact of aluminum profiles on the longevity and strength of a building structure.

- <p>Aluminum profiles significantly enhance the durability of a building due to their high strength-to-weight ratio, excellent resistance to corrosion, and low maintenance requirements. They are lightweight yet strong, making them ideal for load-bearing structures and facades. Corrosion resistance means they withstand harsh weather conditions without rusting, which is common in steel profiles. This durability extends the building's lifespan and reduces the need for frequent repairs or replacements, thereby providing a cost-effective long-term solution. Additionally, aluminum profiles can be easily recycled, contributing to sustainable construction practices.</p>

Send your message to us

T Slot Aluminum Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords