powder coated perforated aluminum sheets plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

powder coated perforated aluminum sheets plates

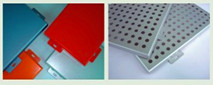

Brief Introduction

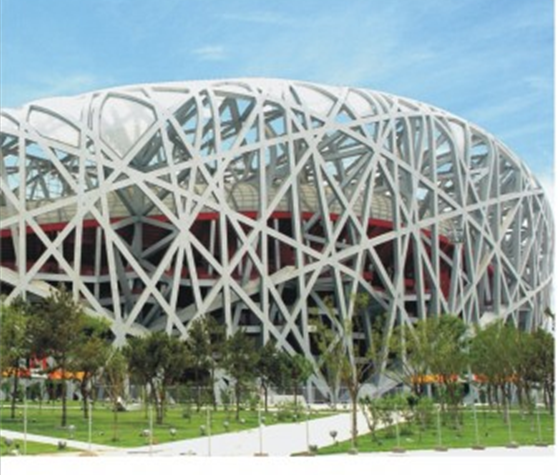

Aluminum Solid Panel is a kind of decoration material scribbled on its surface with fluorine carbon coating and used in cladding.and We are the supplier of 2008 Beijing Olympic Games,16th Asian Games, Guangzhou Baiyun Airport & Guangzhou South Railway Station

1.Characteristics

1) Well weather-resistance and anti-corrosion, high rigidity, easy for maintenance, only neutral cleanser and water needed for its self-clean performance;

2) Easy finishing with conventional working tools. Short time needs for project;

3) Good workability and light weight;

4) High impact-resistance, superior surface flatness, rigid;

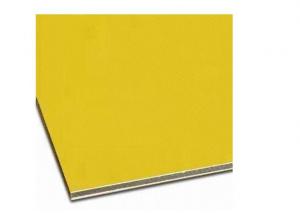

5) Various colors are available according your needs;

6) best price and quick delivery.

2.Applications

1) Exterior applications such as: wall cladding, facades, roofs and canopies, tunnels,

column covers or renovations

2) Interior applications such as: wall cladding, ceilings, bathrooms, kitchens and

balconies

3) Advertisement and market applications such as: display platforms, signboards,

fascias and shop fronts

4) Transport and industry application

3.Colors available:

(1).For general colors, please refer to our ACP color chart

(2).Customized color, please note the following

a. Provide a sample color: better to be a color painted on metal base in order to prevent color difference

b. If you know the factory color code or international standard color code, just provide us with those code number. This could be the quickest and most precise method

c. Normally it will take 1 week for us to counter-provide our color samples for you to compare and confirm by the co-work of our painting experts and the paint suppliers.

d. After receiving our counter-samples, pls. confirm to us as quick as possible on in order for us to set out for production accordingly.

4.Raw Meterials

1.Aluminum alloy:AA1100,AA5052,AA3003 or upon request.

2.Surfce coating:PPG,Akzo Nobel and Nipon,Becker.

3.Shape:Upon on request,including flat,arc,bow and other special shapes.

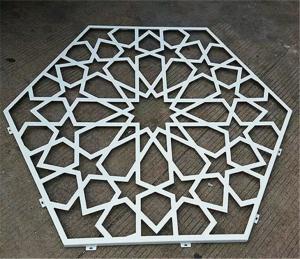

4.Perforation:Different patterns as requirements,we have CNC machine.

5.Specifications

a.Thickness:2.0mm,2.5mm,3.0mm,3.5mm,4.0mm

b.Max Size:1,600mm*4,500mm(Flat)

6.Features

1.Light weight,high strength and rigidity

2.Excellent weather resistance and anti-corrosion

3.Good processing capacity,able to be shaped into flat,arc,globe,ect.

4.Various colors ,good decoration effects

5.Easy to be cleaned and maintained

6.Easy and quick in installation

7.Envirnmental-friendly,able to be recycled

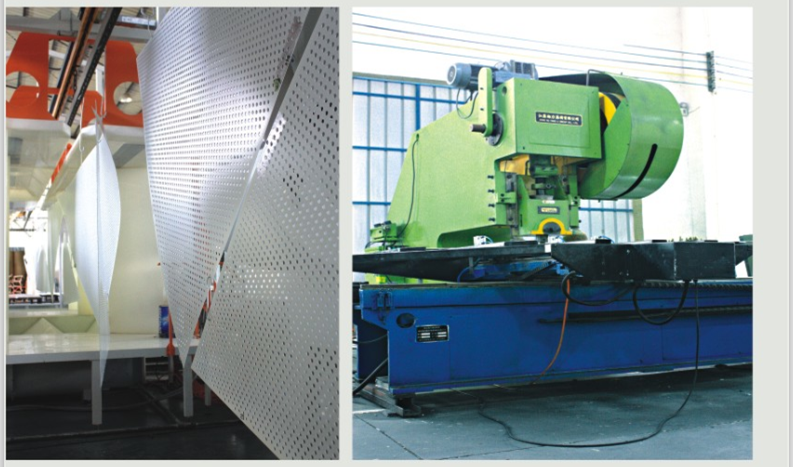

7.production process

1.Project design 2.Cellular drawing 3.Work out procedures 4.Plate check 5.Plate blanking 6.Contour and punch 7.Pressure bend 8.Abnormal shape machining 9.angling & sealing weld 10.Rim angle trimming & loader installation 11.Stud welding reinforcement 12.Surface polish 13. Drug test 14.Clean & chromium 15.Electrostatic spray 16.Quality inspection 17.Film pasting & Packing

8.spraying process

1st coat option:Color top coating

2nd coat option:Base primer+color top coating

3rd coat option:Base primer+Color top coating+top clear coating(protecting paint)

4th coat option:Base primer+Color top coating+Separation coating+Color top coating +top clear coating(protecting paint)

9.Aluminum Alloy guide

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Other | Remain |

| 1100 | 0.4 | 0.55 | 0.05-0.2 | 0.05 | ... | 0.01 | ... | ... | 0.15 | 99 |

| 3003 | 0.6 | 7 | 0.05-0.2 | 1.0-1.5 | ... | 0.01 | .... | ... | 0.15 | aluminum |

10.Dimension avaible

Alloy | 1100,3003 |

Temper | All tempers Subject to alloy |

Thickness | 1.0-6mm for mill finish ,subject to different project |

Width | Subject to customers option,maximun 1.5 meters |

Length | Subject to customers option,maximum 6 meters |

11.Finish introduction:

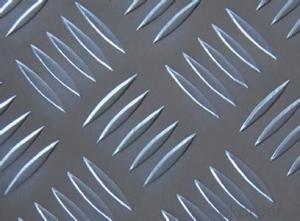

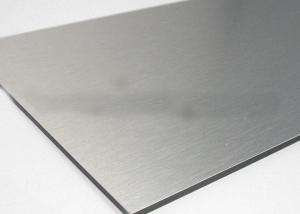

| Mill finish | Finish of aluminum itself,with a natural anodic layer formed in the air,week corrosion resistance | ||||||||

| Powder coating | The powdered paint is electrostatically charged and sprayed onto the part,to form a thick layer to protect the surface.with very good corrosion resistance | ||||||||

Brand:Guangmei

Yellow color Aluminum solid panel,Curtain wall aluminum panel

Aluminum solid panel design

- Q: hi, i live in a dorm room and i want to put up drapes or curtains but i cant make holes/damage the walls. do they have drapes or curtains that dont require holes?

- Look for rods that have are a tension rod.

- Q: Redoing my room and Im not sure what colors I want! lol, been having trouble for awhile. Btw, Im 13, nothing girly or reallt tomboyish either, thanks!

- I think green would be best cause it's not too girlish and not too tomboyish.

- Q: My company has a glass curtain wall project, there are 10,000 square meters, and now the team approach, to provide qualified project manager for the two construction division. OK

- Secondary construction division can not bear 10,000 square meters of glass curtain wall construction, not eligible. According to the scale of the project, single curtain wall with a height of less than 60 meters and a building area of less than 6,000 square meters is a medium-sized project, borne by the secondary construction division. If the area of more than 6,000 square meters, are large projects, need to be born by the professional construction division.

- Q: How to determine the wind resistance performance of building curtain wall

- 1, the curtain wall of the wind pressure performance indicators should be based on the wind wall of the wind load standard value Wk to determine its target value should not be less than Wk, and should not be less than 1.0kPa. Wk shall be calculated in accordance with GB 50009. 2, under the action of the wind pressure performance index value, the curtain wall supporting system and the relative deflection and absolute deflection of the panel should not be greater than the requirements of Table 1 below.

- Q: The difference between component glass curtain wall and all glass curtain wall

- The whole glass curtain wall is a transparent, full-view glass curtain wall, the use of glass transparency, the pursuit of building space inside and outside the flow and integration, so that people can clearly see the glass through the glass structure of the entire system, From a simple support to the performance of its visibility, which shows the architectural decoration of the artistic sense, layered and three-dimensional sense. With light weight, simple selection, processing factory, construction fast, easy maintenance and repair, easy to clean and so on.

- Q: Is not as long as the decoration company can do curtain wall works ah

- Should be a curtain wall construction professional qualification of enterprises can do curtain wall works

- Q: How to take fire protection measures for high temperature welding of curtain wall

- This depends on the working attitude of the workers, the most practical way is to find the process of building a fire board to block.

- Q: How much time is the curtain wall warranty?

- 5 year warranty, 5% warranty, the first year to return 3%, the second year to return 2%. All maintenance within the warranty period is subject to your commitment, as all costs incurred as a result of maintenance are made from the warranty.

- Q: Curtain wall stone around the package window 50, cut the size of the window should be smaller around 50?

- In fact, your question is very vague, such as you listed the window of the empty size, you know how to cut the

- Q: What color do you suggest for window curtains, if the walls are painted light pink?

- I painted our nursery pink and used pink corduroy curtains with the white fringe ball trim. It looks really good and ties everything together. We also used mint green and a butter yellow as the two other colors for accessories and rocking chair.

Send your message to us

powder coated perforated aluminum sheets plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords