Aluminum Perforated Sheets - Finished Aluminium Plate for Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

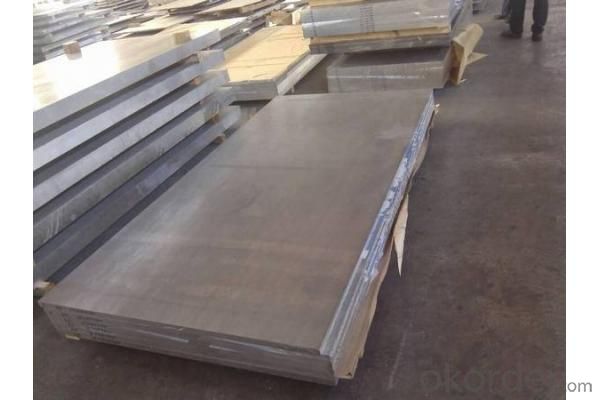

| Finished Aluminium Plate Used For Wall Decoration | |||||

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 25MT. | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set. | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 15-60 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

PVDF and PE coated aluminium coils/sheets:

PVDF color pre coated aluminum coils/ sheets:

It is well known that fluorocarbon lacquer coating (PVDF coating) owes the best acid resistant/alkali and temperature tolerant capabilities of all painting materials. Being the best quality of precoated aluminum, PVDF coated coils are especially suitable for outdoor roofing walls and ceiling manufacturing.

Polyester (PE) color pre coated aluminum coils/ sheets :

Using high-grade polyester lacquer coating material, the finished coated coils are with delicate color uniform texture, color and diverse. It is the most popular and most common used materials in decorative usage. The PE coated aluminum are widely used in ACP( aluminum composite panel ) production and indoor ceiling usage.

Production facilities and processing range

Equipments | Quantity | Thickness range | Width range | Length range | Max loading weight |

Continuous casting rolling mill | 23 | 6.0-10.0mm | 1000-2000mm | ------------- | 15000kgs |

Cold rolling mill | 2 | 0.1-6.0mm | 900-1700mm | ------------- | 12000kgs |

High accuracy cold rolling line | 1 | 0.1-1.0mm | 650-1420mm | ------------- | OD 2000mm |

Annealer | 14x40T | ------------- | -------------- | ------------- | ------------- |

Coating line | 3 | 0.15-1.5mm | 600-1600mm | ------------- | 5000kgs |

Embossing line | 1 | 0.2-1.2mm | 350-1300mm | ------------- | 8500kgs |

Straightening line | 1 | 0.1-2.0mm | 600-1700mm | ------------- | 10000kgs |

Slitting line | 1 | 0.2-3.0mm | 21-1595mm | ------------- | 10000kgs |

Wave shearing line | 1 | 0.13-0.5mm | 550-1230mm | ------------- | 10000kgs |

Shearing line | 3 | 0.125-4.0mm | Max 1700mm | ------------- | 10000kgs |

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: This question asks for methods to guarantee that the edges of installed aluminum sheets remain straight and smooth.

- <p>To ensure that the edges of aluminum sheets are straight and smooth after installation, follow these steps: 1. Use high-quality aluminum sheets that are free from warping or defects. 2. Measure and cut the sheets accurately to avoid any discrepancies. 3. Use a sharp, clean cutting tool to prevent jagged edges. 4. Smooth out any rough edges with a file or sandpaper. 5. Install the sheets with precision, ensuring they are aligned properly. 6. Use appropriate fasteners and brackets to secure the sheets without causing any distortion. 7. Regularly inspect and maintain the sheets to address any issues promptly. By following these steps, you can maintain the straightness and smoothness of aluminum sheet edges after installation.</p>

- Q: Can aluminum sheet be used for soundproofing?

- To a certain degree, aluminum sheet can indeed be utilized for soundproofing. Its dense and rigid composition makes it proficient in obstructing sound transmission. By combining it with other soundproofing materials like foam or mineral wool, its soundproofing capabilities can be further augmented. Nevertheless, it is crucial to acknowledge that aluminum sheet alone may not deliver absolute soundproofing since its thinness can still permit some sound to penetrate. Moreover, ensuring proper installation and sealing of all gaps and openings is imperative to maximize the soundproofing efficacy of aluminum sheet.

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- It should hold up well I don't think there would be any reaction. They use aluminum railings as stairs for large pools. The aluminum might be coated with something else though. Aluminum usually forms a thin coat of Aluminum Oxide, Al2O3, so it should prevent it from further oxidation.

- Q: What is the typical modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets typically ranges around 70 GPa (gigapascals) or approximately 10 million psi (pounds per square inch). Nevertheless, it should be emphasized that the specific alloy and temper of the aluminum sheet can cause variations in its modulus of elasticity.

- Q: Can aluminum plate resist acid and alkali?

- The metal oxide film changes the surface state and properties, such as surface coloring, corrosion resistance, abrasion resistance and hardness, and metal surface protection. For example, aluminum anodizing, the aluminum alloy placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, under certain conditions and applied electricity under the electrolysis. Anodized aluminum or its alloy, formed on the surface of alumina thin layer, its thickness is 5~20 microns, anodized aluminum or its alloy. Therefore, the surface hardness and wear resistance of the aluminum alloy were greatly improved by the treatment process.Shanghai Ai Li AI metal materials, dedicated to serve you.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: Is it feasible to recycle aluminum profiles after their use?

- <p>Yes, aluminum profiles can be easily recycled after use. Aluminum is one of the most recycled materials in the world due to its durability and recyclability. Recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. The recycling process is straightforward, involving melting the aluminum, which can then be reformed into new products without losing its properties. This makes aluminum profiles an environmentally friendly choice for many applications.</p>

- Q: How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ in terms of thickness. Sheets are typically thinner, usually less than 6 mm, while plates are thicker, typically more than 6 mm. Additionally, sheets are often used for lightweight applications such as packaging, whereas plates are commonly utilized for structural purposes or heavy-duty applications.

- Q: Can aluminum sheets be used for signage purposes?

- Yes, aluminum sheets can be used for signage purposes. Aluminum is a versatile and durable material that is commonly used in the signage industry. It is lightweight, corrosion-resistant, and has excellent weather resistance, making it suitable for both indoor and outdoor signage. Aluminum sheets can be easily cut and shaped to create various sizes and designs of signs. They can be painted, coated, or printed on to display logos, text, or graphics. Additionally, aluminum signs are cost-effective and have a long lifespan, making them a popular choice for businesses, construction sites, road signs, and other signage applications.

- Q: What is the typical thickness tolerance for aluminum sheets?

- The specific application and industry standards can cause variations in the typical thickness tolerance for aluminum sheets. Generally, the acceptable range for thickness tolerance is usually between ± 0.005 and ± 0.015 inches. This indicates that the actual thickness of the sheet can deviate within this tolerance range from the specified thickness. It is worth noting that diverse industries may have different tolerance requirements depending on the intended use of the aluminum sheet. Therefore, it is always advisable to refer to the relevant industry standards or specifications for precise tolerance requirements.

Send your message to us

Aluminum Perforated Sheets - Finished Aluminium Plate for Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords