Decorative Perforated Aluminum Sheets - Aluminium Plate and Sheet in Stock

- Loading Port:

- Shanghai

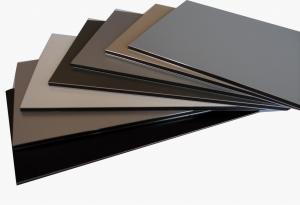

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and hot rolled aluminium sheet are both widely used in the field of construction field and decoration field, etc.

1100, 1050, 1060, 2024, 5052, 5754, 5083, 6061, 6063, 8011, etc.

2. Main features of the product

a.Competitive price

b. Frist-Class Service.

c. quickly shipment service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: Can aluminum sheets be coated with protective films?

- Yes, aluminum sheets can be coated with protective films. These films are typically made of materials such as polyethylene or polypropylene and are designed to provide a barrier against scratches, abrasions, and other forms of damage. The protective film is applied to the surface of the aluminum sheet, creating a layer that shields it from potential harm during handling, transportation, or processing. This coating process helps to maintain the integrity and appearance of the aluminum sheet, ensuring that it remains in excellent condition until it is ready for use.

- Q: Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. It is a versatile material that offers durability, lightweight properties, and corrosion resistance, making it suitable for various architectural projects such as facades, roofing, window frames, and decorative elements. Additionally, aluminum can be easily formed, fabricated, and finished to meet specific design requirements, making it a popular choice in the construction industry.

- Q: You are probably think wtf. Lol, so I just got a Mac and I HATE its keyboard! Also, I have been looking at Fallout 3, and I think its looks amazing! Here is my question: Should I get the new aluminum keyboard for my Mac or Fallout 3? I have $60 to spend and I have found a place to get one or the other for under $60. I could also get on Ebay and get BOTH! Which one/option should I do?

- Have you used the Apple Aluminum keyboard before? Most people either love it or hate it. The low-profile keys feel a lot different than a traditional keyboard. Personally, I like it and can type faster on the AL, but I know a lot of people that got rid of it and got a different keyboard. You don't NEED to use an Apple keyboard on your Mac - you can use any USB keyboard you want. So you COULD get a cheaper alternate keyboard and still get Fallout as well. Windows keyboards don't have the same quick pick button across the top as an Apple keyboard, but you can custom configure your keyboard commands in System Profile-Keyboard Mouse-Keyboard Shortcuts (under the Apple logo at the top-left of your screen) and set whatever keys or key combos to do those missing commands. But I don't think Fallout 3 is out for Mac, is it? I couldn't find a version with a quick Google search.........a Windows version won't run on your Mac unless you have Windows installed with either Boot Camp (included in OS X 10 Leopard) or with a virtual PC like VMWare Fusion or Parallels. Unless you are running Windows on your Mac (like I am) don't waste your money on a PC game you won't be able to play. Enjoy your new Mac!

- Q: Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Yes, aluminum sheets are suitable for HVAC (heating, ventilation, and air conditioning) applications. Aluminum is a popular choice in the HVAC industry due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. These sheets are commonly used for ductwork, heat exchangers, and air handling units in HVAC systems. Aluminum sheets can efficiently transfer heat and withstand high temperatures, making them ideal for heating applications. Additionally, their resistance to corrosion ensures long-term durability in moist environments, such as air conditioning systems. Moreover, the lightweight nature of aluminum sheets simplifies installation and reduces the overall weight of HVAC equipment. Overall, aluminum sheets are a reliable and versatile material for HVAC applications.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Indeed, it is possible to paint or coat aluminum sheet after it has been fabricated. Aluminum, being a versatile material, lends itself easily to being painted or coated in order to improve its appearance or provide extra protection. The procedure involves preparing the surface through thorough cleaning and the elimination of any impurities, followed by the application of a primer to enhance adhesion. Once the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The choice of paint or coating will depend on the intended usage and the specific requirements of the application. All in all, painting or coating aluminum sheet after fabrication is a widespread practice that can significantly enhance its aesthetics and durability.

- Q: What are the safety standards for using aluminum sheets in construction?

- <p>Yes, there are safety standards related to using aluminum sheets in construction projects. These standards ensure the material's structural integrity, durability, and safety. They include specifications for thickness, strength, and quality of aluminum sheets, as well as guidelines for their installation to prevent issues like corrosion, fire hazards, and structural failure. Compliance with these standards is crucial for the safety of the construction workers and the longevity of the building.</p>

- Q: What is the price range of 101 aluminum sheets?

- The price range of 101 aluminum sheets can vary depending on factors such as size, quantity, and supplier. However, generally speaking, the price range for 101 aluminum sheets can be anywhere from $50 to $150 per sheet.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- First calculate the density of each aluminum plate, then calculate the volume, then the density is good, the volume is the weight

- Q: Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and high heat resistance. It helps to protect sensitive components from excessive heat by reflecting and dissipating the heat away from the desired areas. Additionally, aluminum is lightweight and corrosion-resistant, making it an ideal material for automotive applications. It is commonly used in various heat shield designs, including exhaust heat shields, engine heat shields, and under-carriage heat shields.

Send your message to us

Decorative Perforated Aluminum Sheets - Aluminium Plate and Sheet in Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords