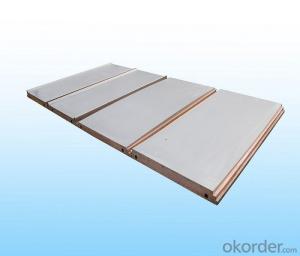

polished copper sheet-plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard export package, as per as customer required if any |

| Delivery Detail: | 10-15 days after reciving the deposit |

Specifications

polished copper sheet/plate

1.Spe.:2*1000*2000mm

2.Decoration

3.Applicable standards:JIS,DIN,ASTM,EN

4.Excellent plasticity

Polished copper sheet/plate c1100

Specification:

1.Thickness:0.3-160mm, Width:100-3499mm

2.Standard:GB/T 2059-2000

3.Hardness:O,1/2H,3/4H,H,EH,SH and so on

4.Applicable standards:GB,JIS,DIN,ASTM,EN

5.Application:all kinds of deep drawing and bending stress parts manufacturing, such as pin rivet washer nut catheter barometer screen radiator parts, etc

Advantages:

1.High efficiency, energy saving healthy

2.Excellent plasticity

3.Excellent corrosion resistance

4.Good cutting performance

Mechanical property:

Temper | Temper | Tensile MPa | Elongationð10(%)≥ | HardnessHV |

Soft | M | ≥195 | ≥30 | ≤70 |

1/4 hard | Y4 | 215-275 | ≥25 | 60-90 |

1/2 hard | Y2 | 245-345 | ≥8 | 80-110 |

Hard | Y | 296-380 | ≥3 | 90-120 |

Extra hard | T | ≥350 |

| ≥110 |

Copper Trade Name:

GB | ISO | ASTM | JIS | BS | DIN | EN |

TU2 | Cu-OF | C10100 | C1011 | C101 | OF-Cu | CW008A |

T2 | Cu-FRHC | C11000 | C1100 | C101 | E-Cu58 |

|

TP2 | Cu-DHP | C12200 | C1220 | C106 | SF-Cu | CW024A |

TP1 | Cu-DLP | C12000 | C1201 |

| SW-Cu | CW023A |

- Q:A square hole 8.00 cm along each side is cut in a sheet of copper. Calculate the change in the area of this hole resulting when the temperature of the sheet is increased by 48.0 K.We don‘t know where to start on this.

- The starting area of this circle is a(pi)r^2 , where r 4cm (or one-half of L) You need to look up, in your book most likely, the coefficient of thermal expansion for copper. It is most likely given in degrees Celsius, so make sure to convert your Kelvin temperatures, accordingly. You should also be able to identify the thermal expansion equation: the change in length of a material is equal to the initial length of the material multiplied by the coefficient of thermal expansion for the material multiplied by the change in temperature of the material. This gives you the CHANGE in the LENGTH of the material. Now, calculate the area of the circle after expansion: A (pi)R^2 , where R is equal to half of the sum of L plus the change in L: R [L + (change in L)]/2 Finally, subtract these two quantities to find your change in area: change in area: ( A - a ) pi(R^2 - r^2) pi([(L/2)^2] - [(L + change in L)/2]^2]) Love the physics.

- Q:are copper washers and crush washers the same?

- The crush washers are probably extruded as pipe or sheet and cut or stamped into washers whereas the others were probably stamped or cut from a copper cast. The crush washers can be bent back and forth a few times without breaking but a cast washer would break right off.

- Q:hi my question is:why is a PCB exposed to UV light. what does the light do to the board?Cheers Av

- PCBs start as a board covered by a solid sheet of copper and then a special photo-resist layer. The photo-resist is such that when developed it only remains if it has not been exposed to UV light, and it resists acid eating away the copper layer. In other words, the area exposed to UV light, when dipped in acid, is eaten away. Those areas not exposed to UV light 'resist' the acid and remain. By exposing to UV light through a drawn or printed pattern, you can precisely control what areas are or are not exposed. If you didn't expose to UV light before the acid dip, all the photo-resist would remain and you would end up with a solid copper sheet left on the board rather than traces and part pads.

- Q:Im building a Zinc carbon battery from scratch for an engineering project at school.so I have two batteries made and each produce about 1.3-1.6 volts but I can‘t seem to get any amps so i can run a small fan with them.can anyone help me troubleshoot this one?I am using the carbon rods and shells of store bought zinc carbon batteries and preparing the paste (Mang. Oxide, carbon powder, ammonium chloride, water) and then adding it tothe the shell.the inside of the shell is lined with paper.

- I wonder if the paper liner is blocking free access of the paste to the zinc shell. Try it without the paper liner. Whenever I have taken carbon-zinc batteries apart I don't remember finding any paper between the zinc shell and the filler material. Also, I presume when you say Mang Oxide you are definitely using manganese dioxide, not magnesium oxide. For you project, it seems like you are taking a dry cell apart and re-constructing it, it might be more interesting to build wet-cell batteries, as people would be able to see the different parts of the cell in action. One of the simplest would be a piece of sheet copper and a piece of sheet zinc in a glass jar of dillute acid (such as HCl). You can hook several of these cells together in series to get the voltage you need. You will need to experiment with what size sheets and how far away they are spaced, acid concentration etc to run your fan.

- Q:0.5 mm copper plate with that kind of welding?

- Can also be welded by braze copper, if copper is then self fluxing with Wei Odin 202A solder, liquefied gas gun as heat source, welding powder do not, if it is yellow copper, with the same wire heating source, the same, just need to paste with the use of 201-F to Odin wei.

- Q:what is solar panel?and what is solar cell?do solar cells compose solar panels?

- solar panels trap energy from the sun inside itself, and then you can later used it for energy. I think everyone should get some solar panels.

- Q:I am wanting to learn to make copper water features, just getting started, do you weld copper or braise it? Help. Where do you buy the sheets of copper too? thank you

- Brazing involves high temperatures and a filler material (usually brass rod). What you want to do is called soldering. Just takes a Bernz-o-matic torch, flux and solder. Larger sheets of copper would probably be found only at metal shops. Not a cheap item currently.

- Q:Why did Conany ask people to touch the copper plate to see if there was potassium cyanate in his hand?

- Because potassium cyanate and copper chemical reaction, there is a phenomenon to detect whether there is potassium cyanate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

polished copper sheet-plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords