Blister Aluminum Foil Hot Rolled Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminum Foil Hot Rolled Checkered Steel Plate:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of Aluminum Foil Hot Rolled Checkered Steel Plate

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

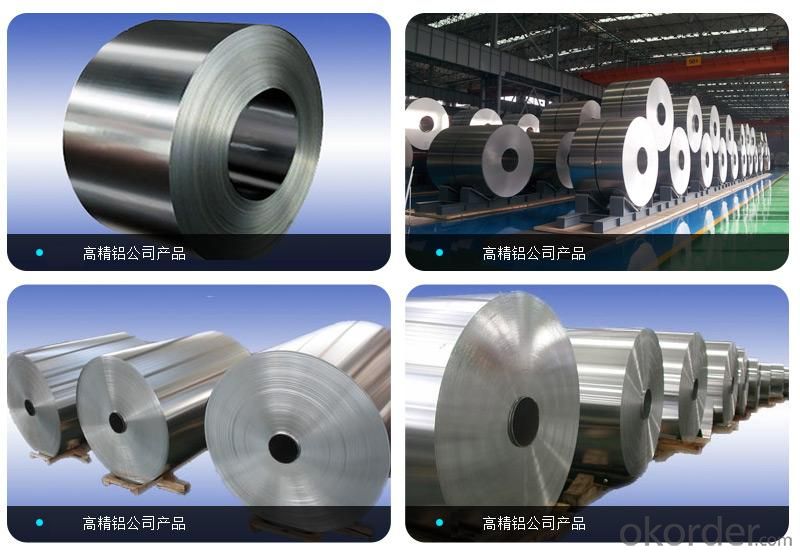

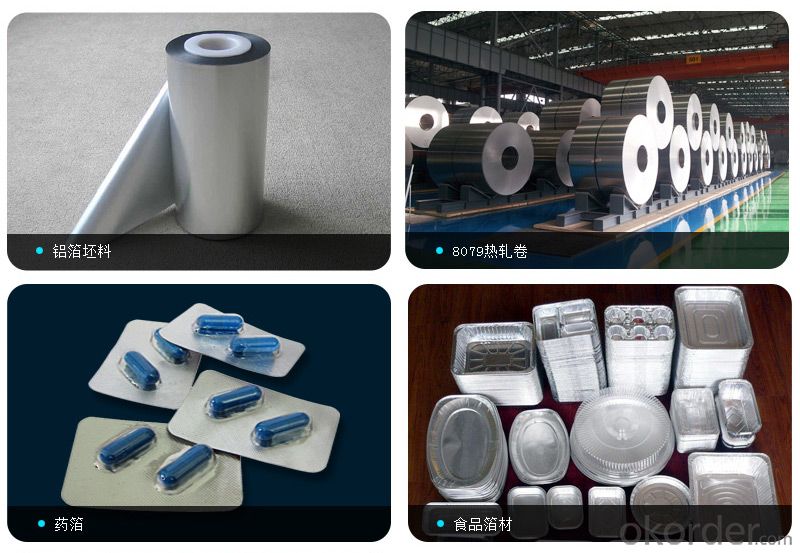

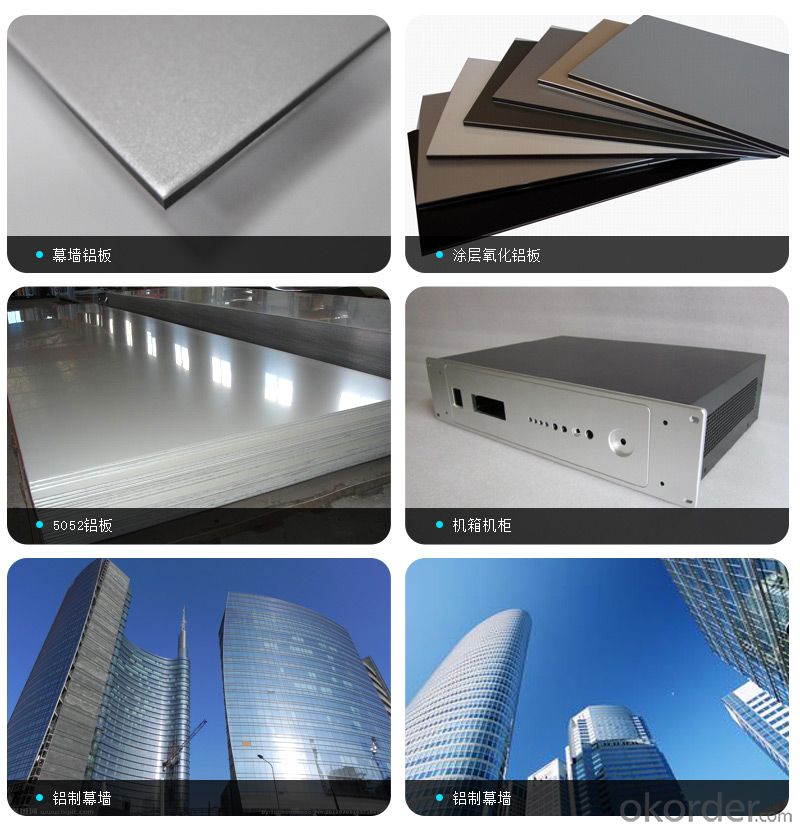

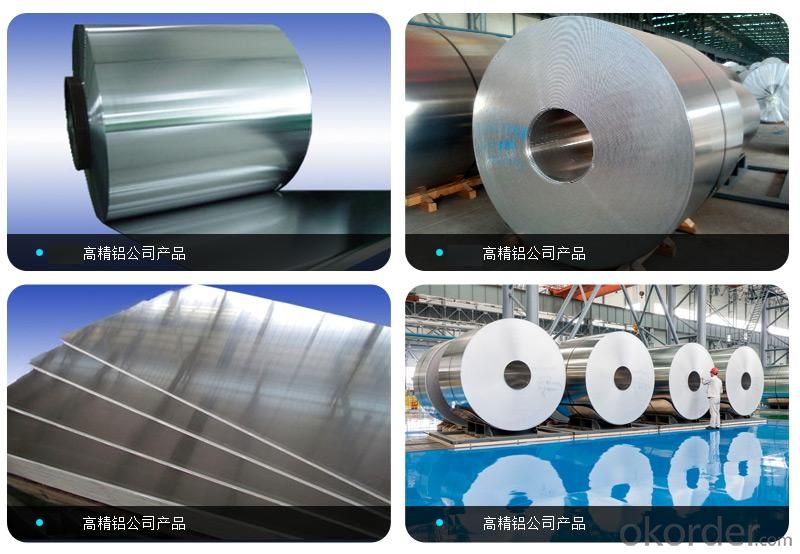

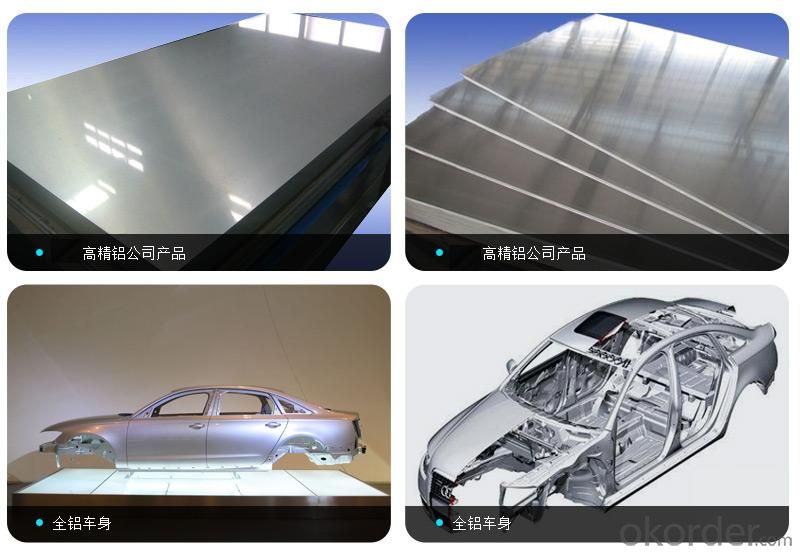

Images of the Aluminum Foil Hot Rolled Checkered Steel Plate:

Aluminum Foil Hot Rolled Checkered Steel Plate Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

Production Aluminum Foil Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: Going up north to Masswhere they dont have it and im flying from texasSomeone up there really loves it so its the least i could doshould i freeze it and then just travel with it as a carry-on or freeze and then.i dont know! what could i do???????

- Freeze the foodPack in a plastic zipper bagPack the frozen pack inside the zipper bagWrap in aluminum foil to keep the temperature intactPlace all of it in an insulated cooler or cooler bag and ship as luggageYou should be fineI would not take it through security because, again, you never know who is going to make a fuss about itI really wouldn't try to carry it onI don't think you can anymoreFreeze it and check it as luggage.

- Q: need machine to mass produce product!

- The roar was present in the first Godzilla movie (1954) and was created by composer Akira Ifukube who produced the sound by rubbing a resin-covered leather glove along the loosened strings of a double bass and then slowed down the playbackOver the years the roar has become a trademark sound of the Godzilla films and is now instantly recognizable to a large audience.

- Q: We have a 1999 Trails West steel horse trailer, and the back door has rotted through.The door is basically square steel tubing welded together in a frame with a sheet of steel over the frame.It's easy enough for me to just build a whole new door instead of trying to fix this one or buy a door from Trails West, but I don't know what thickness of steel I should be using, and the door is so rotted and has flaked off shavings of rust to the point that I can't tell what thickness the original door was made out of.What thickness steel would you use for the sheet of steel? And what wall thickness would you use for the square tube?I considered making the door out of aluminum to save weight, - so if I were to go that route, again, what thicknesses of aluminum sheet/square tube would you go with the maintain the same strength that steel would offer?Bare in mind that, if going steel, I don't want to go thicker gauge than the original door, because steel is heavy, so please don't be conservative LOL.

- Thick enough the horse doesn't fall outI would not use less than 1/8 that would be a good start for the tubeAssuming it is a swing gate cover it with 22 gauge sheet metal on the outside and maybe plywood or rubber on the insideIf you use aluminum you will have to protect it from the dissimilar metals (steel and aluminum don't like each other especially in that type of atmosphere, wet and poo)You would need stainless steel hinges and fasteners alsoIf you go aluminum hope you have the equipment to weld it, bolting only won't hold.

- Q: how do i make the model out of house hold items??im only in 8th grade so a good detailed explanation nice

- high fiber: whole grain bread rice or pastaoatmeals high protein: red meat, fish, chicken

- Q: The cookie I am looking for is sold at a local bakery and she calls them brownie cookiesThey are deliciousMy friend and I renamed them Slap-yo-Mama cookies because they are so good you would slap you mama to get another lol

- Spirits work in strange ways and unlike us on earth they have the power to work when they wantis very rare for a spirit to communicate with earth beings by physical power- its usually a bad spirit who has anger that will physically move thingsWould you really want new buildings etc to start off with a bad spirit in it? I think not!

- Q: i need to bake chicken drumsticks coated with breadcrumbs for tonight's dinner but I'm not going to be home at the time it's neededCan I prepare it now and refrigerate and then have someone bake it?

- Yes! Dry the chickenDip it in milk, then in seasoned flourI brush a coat of whipped egg over the floured leg and then roll the leg in the seasoned bread crumbsLay the coated legs on the baking trayArrange them as if they were going into your ovenCover with aluminium foil, RefrigeratePrint a note telling your helper how you want them bakedOven temperature, shelf level, and bake timeWork out the start bake time so the legs will be ready for your dinner.

- Q: I want to get a guitar amp that is small enough to fit on a scooter/motorbike/vespa.I also want to get a scooter/motorbike/vespa that would be good for carrying my amp around onAny suggestions for either of these?Also any advise about how to attach the amp?

- i would think all states vary.new construction yes.if you need insul.in your attic.i would do it.good luck.

- Q: My family are coming to my house for Christmas dinner this yearWe've just had a big new house built and will be having a baby around the very end of Nov or the very 1st of DecSo any ideas to side dish recipes I can make with my turkey? Any holiday drink ideas as well? Thank you!

- I would splurge for the parking tag if you can get oneTow trucks dont give one about your car, and since your in the wrong for parking there anything that happens to your car is not going to be their faultIf you park in gear and set your e-barke they are going to hook up to your front end or what ever end they can get ahold of and drag it off, even if it ruins your tires and transmissionSo I would take this seriously, if you like your cargood luck

- Q: What are the primary applications or functions of aluminum foil?

- <p>Aluminum foil is primarily used for food storage and cooking. It is known for its excellent heat conduction properties, making it ideal for cooking and baking. It is also used for wrapping and preserving food to maintain freshness. Additionally, aluminum foil is utilized in the pharmaceutical industry for packaging, in construction for insulation, and in various industrial processes due to its malleability and resistance to corrosion.</p>

- Q: Why do you need to use alumni foil in covering the yogurt? Why do you need to heat the milk mixture at 90 de?

- Um, not sure I understand your first question, but yogurt is usually covered with aluminum foil or something else while it's incubating to keep any other bacteria besides the ones you're intentionally using to make your yogurt from getting into the milk and changing the taste/etcof the finished yogurt There are all kinds of bacteria (good and bad) floating around in the air at all times, but you'll want only the ones present in the culture you're using to ferment your milk Yogurt is also usually covered while it's in the refrigerator after incubation to keep flavors elsewhere in the frig from being absorbed by the finished yogurt(Uncovered foods can lose some of their water in the frig too because it's a drying environment.) As for having to heat the milk to 90 degrees, you don't say if you mean 90 centigrade or fahrenheit, and I don't know where you are so can't guess which it's more likely to be 90 degrees C is equal to 194 degrees F thoughGenerally for homemade yogurt, the best temperature for fermenting the milk is 115-120 F, which isn't really either of the possibilities for 90(Too much hotter than that temprange and the bacteria will be killed, but too much lower than that and the bacteria will just get slowed way down so fermentation takes much longer.) Also, before fermentation many people like to make a thicker yogurt than can usually be made at home (manufactured yogurts usually add starches, gelatins, etc.) so those people will often heat their milk to 185 F (which is close to 194 F, I guess) in order to make the finished yogurt thicker than it would have been if not heated that high (Usually then it's best to keep it at about that temp for a few minutes at least, and then cool it slowly and naturally, for the thickest results.) When the yogurt cools to 115-120, the culture is then added and fermentation beginsHTH, Diane B.

Send your message to us

Blister Aluminum Foil Hot Rolled Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords