Reynolds Super Strength Aluminum Foil Bags for Building Insulation Ducting Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminium foil (or aluminum foil) is aluminium prepared in thin metal leaves with a thickness less than 0.2 millimetres (8 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used.In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). Thefoil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimeslaminated to other materials such as plastics or paper to make them more useful. Aluminium foil supplantedtin foil in the mid 20th century.

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans").Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals.Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

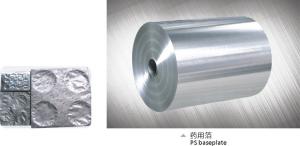

2.Specification

OTHER FOIL OTHER ALUMINIUM FOILs FOR PACKING ELSE

ALLOY:1050/1100/8011

TEMPER:O

THICKNESS: 0.01mm-0.2mm(±8%)

WIDTH:200mm-1650mm(±1mm)

MECHANICAL PROPERTIES: TENSILE STRENGTH (U.T.S)≥40Mpa, ELONGATION≥1%

STANDARD:GB/T3198/ASTM-B209/EN546

3.Application

APPLICATION:FOIL BAGS, BUILDING INSULATION, DUCTING PIPE

4.Pictures

5.FAQ

1)What's our packaging and Delivery?

| Packaging Details: | packed in wooden box or pp bag or shink. |

| Delivery Detail: | 25-35day |

2)How about our payment term?

LC and TT and other.

3)Which country can we supply?

All around the world!

- Q: I know that Aluminium is the best conductorSi being a semi-conductors and others being non-conductorsso shouldn't the trend be Nagt;Mggt;Al? with Si being a worse conductor than Na?Because why is Aluminium the best electrical conductor? because if it has the highest nuclear charge then wouldn't that mean the sea of electrons will be closer to the nucleus and therefore the flow of electrons would be greatly inhibited causing it to be a worse electrical conductor than sodium and magnesium?

- Al can give up THREE electrons to the Sea

- Q: I have a 1991 toyota pickup with the 3vz-e v6 engine option, and the head gasket blewThe gaskets are faulty because there was a factory recall on them and its very apparent why they leakedThe engine didnt overheat but they are aluminum headsi got them roughly checked and they seemed to be in toleranceive heard from many sources that you should get the heads resurfaced and change the head bolts as precaution but we want to avoid these things(the bolts because it would require removal of cams and they are torqued very tight and i already have the heads off so id have to put them back on the engine to get the cams out) so does anybody know if itd be a a risk worth taking just putting on replacement gaskets and reusing the bolts? i am aware that its a possible risk doing so but im trying to weigh my options.

- nope, but if you jump into it too soon, you could get alot of gas, and even constipation from too much fibergood luck!

- Q: Does anyone know what the deal is or where to find it?

- Well, you start with an aluminum rich rock (cheaper to process)The raw ore after physical concentration (removal of secondary minerals) is reacted by an electrolytic processThis means that electricity is used to convert the aluminum ion in the raw rock into the metal aluminumSort of like the reverse of a battery, to keep things simpleAluminum smelters tend to be set up in places with cheap electricity, because the process uses a LOT of electricityThat is why there are several up here in quebec, we have cheap hydro electricity and the government gives decent deals to the smelters on top of the already low market priceDo a search on aluminum smelting to find out moreNot sure what your level of knowledge is so not sure how much you will understand.

- Q: I uderstood that minerals will not dissapear or whatever if you cook water, so if the water evaporates , but i leave a little of it , will it be very mineral dense? and could i by adding more water and cooking it again till theres a little left and repeating crete like a quot;mineral bombquot;, or is the mineral content in water already saturated from the start? if sowhere do the minerals go after the water evaporates and is there another way to catch them?

- Russian Front movies- check these films out Cross Of Iron Stalingrad Europa Europa Come And See

- Q: Normally when I wrap them up and bring to scool, it already tastes soggy.any idea?

- Wrap everything separatelyPut the tortillas in aluminum foil and put the meat in a small tupperware bowlPut veggies, cheese, etc in a plastic sandwich bagThat way, your tortillas won't get soggy.

- Q: This question asks if there are any positive effects on health from the regular use of aluminum foil.

- <p>There are no significant health benefits associated with the regular use of aluminum foil. While it is a common material used for food storage and cooking due to its ability to retain heat and prevent food from drying out, there are concerns about potential health risks. Some studies suggest that aluminum exposure could be linked to neurological disorders, although more research is needed to establish a definitive link. It is generally safe to use aluminum foil for cooking and food storage, but it's important to be aware of the potential risks and use it responsibly.</p>

- Q: Determine if the following compunds are likely to have ionic or covalent bonds.Amagnesium oxide, MgOBstrontium chloride, SrCl2Cozone, O3 Dmethanol, CH4O2Identify which two of the following substance will conduct electricity, and explain why.Aaluminum foilBsugar, C12H22O11, dissolved in waterCpotassium hydroxide, KOH, dissolved in water4Predict wheather a silver coin can conduct electricitywhat kind of bonds does silver have?5Describe how it is possible for calcium hydroxide, Ca(OH)2, to have both ionic and covalent bonds6Explain why electrons are shared equally in ozone, O3, and unequally in carbon dioxide, CO2.

- As shown where? What's the question? haha -Duo

- Q: i made a works bomb with a pop bottle toilet bowl cleaner and aluminum foil how long should it take to explode?

- It is very unpredictable, a search on youtube will yield a score of idiots that had it blown in there hands, there's much better things to do in life than that.

- Q: An aluminum sphere (specific gravity 2.7) falling through water reaches a terminal speed of 3.1 cm/sWhat is the terminal speed of an air bubble of the same radius rising through water? Assume viscous drag in both cases and ignore the possibility of changes in size or shape of the air bubble; the temperature is 20°C where air density is 1.20 kg/m3 and water density is 1001.80 kg/m3.

- Weight of aluminium sphere(volume V) is: WA V x 2.7x1001.80 x 9.81 26534.6766V Weight of air bubble, WB (volume V) is: WB V x 1.20 x 9.81 11.772V Upthrust (buoyancy force) on both sphere and bubble: U weight of water displaced U V x 1001.80 x 9.81 9827.658V From Stoke' law, viscous drag D is proportional to speed, other factors being the same: For sphere with speed vA, drag force is DA kvA 0.031k For bubble with speed vB, drag force is DB kvB At terminal velocity the resultant force 0For the sphere falling: weight upthrust + drag force 26534.6766V 9827.658V + 0.031k k 16707.0186V/0.031 538936.0839V For the bubble rising : weight + drag force upthrust 11.772V + kvB 9827.658V Substituting for k 11.772V + 538936.0839VvB 9827.658V 11.772 + 538936.0839vB 9827.658 vB 9815.866/538936.0839 0.0178 m/s 1,8cm/s (Arithmetic not guaranteed!)

- Q: I want to try and make hydrogen but i am not sure what concentraion of HCl to use and how muchAlso I am not sure how much grams of aluminuim foil to useCan anyone help pls.

- For a given dimension, square tubing is the stiffest, but also the heaviestAs for what dimension of tubing, we don't know enough about the design to give a meaningful answerLarger tubing will give more triangulation within its structure, making it stifferMore actual triangulation will negate the need for the large diameter tubing to provide its own structureUnless you have extensive testing facilities, I'd stick with steelHeat treating involves heating up the metal to a certain temperature, and then cooling it off at a specified rateSome heat treatments involve slowly cooling the metal over 12 or more hours, some involve water quenching to cool it almost instantly, others something in betweenThe purpose of heat treating is to align the crystals in the metal matrix, to provide the optimal balance of stiffness and brittlenessDifferent procedures produce different results, so choosing the right treatment for the application is part of the jobIt's IMHO best left to a specialist, who I guess would be referred to as a 'heat treater.' On another note, welding will affect the heat treatment of the metal involved; so most alloys - steel or aluminum - need to be treated after welding, to restore their full strength.

Send your message to us

Reynolds Super Strength Aluminum Foil Bags for Building Insulation Ducting Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords