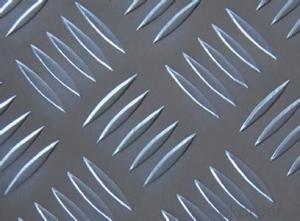

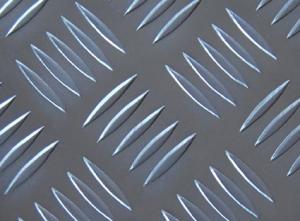

Diamond Checker Plate Aluminum

Diamond Checker Plate Aluminum Related Searches

Checker Plate Aluminum Polished Aluminum Checker Plate Aluminum Checkered Plate Polishing Checker Plate Aluminum Black Aluminum Checker Plate Diamond Checkered Plate Aluminum Checker Plate For Sale Checker Plate Aluminum Price Polished Aluminum Diamond Plate Aluminium Checkered Plate Aluminum Checker Plate Price Polishing Aluminum Checker Plate Aluminum Diamond Deck Plate Buy Aluminum Diamond Plate 1 4 Aluminum Checker Plate Aluminum Black Diamond Plate Aluminum Checker Plate Sheet Aluminum Checker Plate Suppliers Diamond Plate Sheet Aluminum Black Diamond Plate Aluminum Colored Aluminum Diamond Plate Diamond Plate Aluminum Polish Aluminum Diamond Plate Panels Aluminum Sheet Diamond Plate Checker Plate Aluminum Sheets Black Aluminum Diamond Plate 1 8 Aluminum Checker Plate Sheet Diamond Plate Aluminum Aluminum Diamond Plate Polish Aluminum Diamond Plate CoolerDiamond Checker Plate Aluminum Supplier & Manufacturer from China

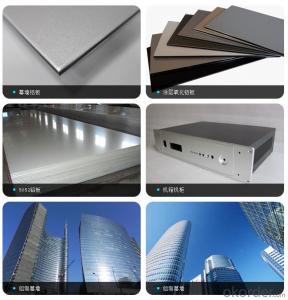

Diamond Checker Plate Aluminum is a type of aluminum sheet material that features a distinctive diamond pattern on its surface, providing enhanced traction and slip resistance. This unique design makes it an ideal choice for various applications where safety and durability are paramount. The product is widely recognized for its excellent performance in both indoor and outdoor environments, making it a popular choice for a range of industries.The Diamond Checker Plate Aluminum is commonly used in construction, automotive, marine, and industrial settings due to its robustness and slip-resistant properties. It is particularly favored in areas where heavy foot traffic or equipment movement is expected, such as walkways, ramps, platforms, and flooring. Its non-slip surface ensures safety underfoot, reducing the risk of accidents and injuries. Additionally, the aluminum material is lightweight, corrosion-resistant, and easy to maintain, making it a cost-effective solution for long-term use.

Okorder.com is a reputable wholesale supplier of Diamond Checker Plate Aluminum, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products are of the highest standard and are available at competitive prices. Their extensive range of Diamond Checker Plate Aluminum allows customers to find the perfect fit for their specific requirements, whether it's for a small-scale project or a large-scale industrial application.

Hot Products