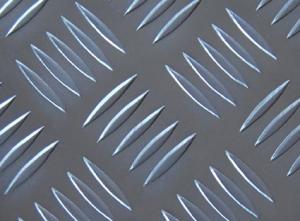

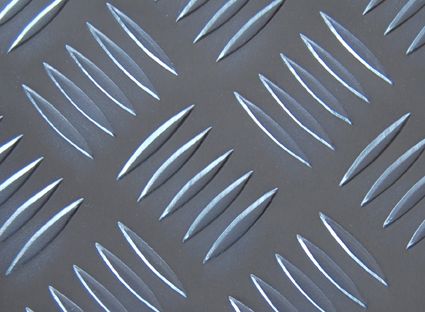

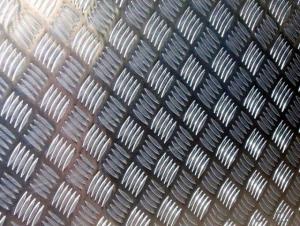

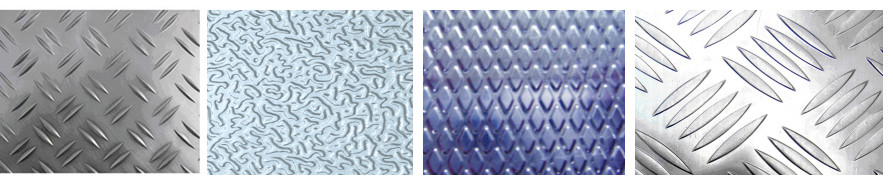

Foam Core Aluminum Sheets - 3003 3004 5052 5754 Five Bar/Diamond Aluminum Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum checkered sheet / plate 3003

1. Alloy: 3003

2. Temper: O-H112

3.Ridge Length: 38mm; Ridge height:0.8-1.2mm

4.Thickness: 1.0-6.0mm

5.Width: 500-2300mm

6.Length: 500-10000mm

7.Main application:

1)Transport vehicles

2)Industrial sheds

3)Fabrication industry

Chamical Components of 3003

Manganese (Mn) | Silicon (Si) Max | Copper (Cu) Max | Iron (Fe) | Zinc (Zn) | Aluminum (Al) |

1-1.5 | 0.6 | 0.2 | 0.7 | 0.15-0.35 | Remainder |

Mechanical Pproperties

Tensile Strength (PSI) | Yield Strength (PSI) | Elongation in 2" |

22,000 | 21,000 | 10 |

Packaging & Delivery

| Packaging Details: | 20-30 days |

| Delivery Detail: | Export standard, covering with plastic film, packed with wood |

FAQ:

Q1.Are you factory or trading company?

A1.We are factory with export rights.

Q2.How many workers in your company?

A2.Around 100-150.

Q3.How long have you been in this product?

A3:More than 10 years.

Q4.What’s your main markets?

A4. Southeast Asia, Mid East, South America ,Africa, Eastern Europe

Q5.What's the minium quantity(MOQ)?

A5.2 Metric tons

Q6.How long is shipping time?

A6.Depending on your quantity normally 15-30 days..

Q7.How do you guarantee the quality?

A7.Professional workers and advanced equipment, all according to the quality standard and client request. QC will check the quality before packaging.

Q8.Do you have after sale service?

A8.Yes.Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can 101 aluminum sheets be embossed or textured?

- It is possible to emboss or texture 101 aluminum sheets. Aluminum is a highly adaptable material that can be easily molded and formed. To emboss or texture aluminum sheets, pressure or heat is applied to create patterns that are either raised or recessed on the surface. There are different methods available for this process, including mechanical embossing or chemical etching. As long as the aluminum sheets are of suitable thickness and good quality, it is feasible to achieve desired designs and patterns through embossing or texturing.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: Don't you know how you can grind a pair of scissors along a piece of paper to make it curly? Would that work with aluminum foil? I have to make a sculpture for my 3D class and I need to know if this would work before I go off and buy any.

- yes is it possible to make a ribbon out of aluminum foil if it is should i use the shiny or matte side for further ribbons out aluminum foil detail see here:

- Q: Are aluminum sheets suitable for food storage containers?

- Yes, aluminum sheets are suitable for food storage containers. Aluminum is a safe and durable material that is resistant to corrosion, making it ideal for storing and preserving food. It also has excellent heat conduction properties, allowing for even cooking and reheating.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Indeed, aluminum sheets prove to be a fitting material for the production of aircraft wings. In the aerospace sector, aluminum is extensively utilized owing to its remarkable strength-to-weight ratio, ability to resist corrosion, and high thermal conductivity. These attributes render it an ideal option for fabricating aircraft components that are both lightweight and robust, such as wings. Aluminum sheets can be easily molded, fused, and processed, enabling the creation of intricate wing designs. Furthermore, the low density of aluminum aids in reducing the overall weight of the aircraft, thereby enhancing fuel efficiency and maneuverability. In summary, the utilization of aluminum sheets in the manufacture of aircraft wings is a prevalent and validated practice within the aviation industry.

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- They felt that used to be the case because of the aluminum seeping into the food. Hard to find an uncoated aluminum pot now. You get more aluminum from deodorants and antacids than cookware. You shouldn't though cook or store tomatoes in aluminum...and that's just the reaction in chemistry.

- Q: Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q: This question asks for a method to measure the thickness of an aluminum sheet.

- <p>To determine the thickness of an aluminum sheet, you can use a micrometer or a caliper, which are precise measuring tools. Place the sheet on a flat surface and measure from one side to the other at multiple points to account for any inconsistencies. Alternatively, you can use an ultrasonic thickness gauge, which is especially useful for non-contact measurements. For a quick estimate, a simple ruler can give you a rough idea, but for high precision, specialized tools are necessary. Always ensure the measuring device is calibrated and used correctly to get accurate results.</p>

Send your message to us

Foam Core Aluminum Sheets - 3003 3004 5052 5754 Five Bar/Diamond Aluminum Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords