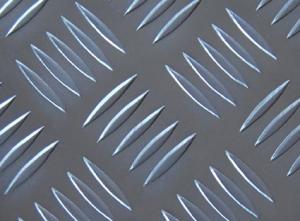

6063 Aluminum Coil Manufacture Five Bar Pattern 5052 4mm Aluminum Checkered Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

5052 4mm aluminum checkered plate

Alloy:1050 1060 1070 1100 3003 5052

Partterns:diamond ,Two,three,Five Bar

Temper:O-H112

Thickness:0.3-8 mm

packing:wooden pallet,wooden case or as customer request

Application of Aluminum Durbar floor plate : Indoor and outdoor decoration, flooring, stairs, construction

Payment: TT or LC .

Company Information

Through the years, we have built many modern production lines, including one 1+2 hot rolling production line, six 2,450, 2,050, 1,650 and 1,450mm cold rolling lines, two 1,650mm foil rolling production lines, two 1,850mm continuous rolling production lines and one roll coating production line. Besides, we also bring in 8 x 20 annealing furnaces, tension leveled machines, tension pre-stretch machines, cutting machines, cleaning equipment, testing machines and packing equipment from at home and abroad to be able to complete various clients' requirements

FAQ

Q: Which country CNBM export to ?

A: Export to over 30 countries, especial Brazil, Chile, Iraq, Australia.etc

Q: What can we expect from CNBM?

A: Yes, as customer request

Q: Can I have some samples?

A: Of course, samples are free (1-3 pcs) or 2-3 kg

Q: When can we get samples and goods?

A: Samples will be sent immediately if have stock, make new will take 2-3days.

Goods will be shipped within 20 days after order confirmed

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 20~25DAYS |

- Q: How do aluminum coils contribute to the thermal conductivity of products?

- Aluminum coils play a significant role in enhancing the thermal conductivity of various products. Due to the exceptional thermal properties of aluminum, coils made from this material are highly efficient at transferring heat. The thermal conductivity of aluminum is much higher compared to other common metals, such as steel or copper. This means that when aluminum coils are used in products, they can quickly and effectively transfer heat from one area to another. For instance, in HVAC systems, aluminum coils are often utilized in air conditioning units. When the refrigerant flows through the coils, the aluminum material rapidly absorbs the heat from the surrounding air. This allows for efficient cooling, as the heat is quickly transferred away from the air and expelled, resulting in a more comfortable indoor environment. Similarly, in heat exchangers, aluminum coils facilitate the transfer of heat between two fluids or gases. The high thermal conductivity of the aluminum allows for efficient heat exchange, ensuring that the desired temperature is achieved in a timely manner. Moreover, aluminum coils are lightweight, which makes them more convenient to handle and install in various products. This characteristic is particularly advantageous in industries such as automotive, aerospace, and electronics, where weight reduction is crucial. In summary, aluminum coils significantly contribute to the thermal conductivity of products by efficiently transferring heat due to their high thermal conductivity properties. Their lightweight nature further enhances their versatility and practicality in multiple industries.

- Q: What is color aluminum coil?

- Colored aluminum coil is that the aluminum alloy whose surface has been shaded. The surface color after special treatment will not fade within 30 years at least because of the stable performance and good corrosion resistance. The weight per unit volume of color aluminum coil is the lightest among metal materials because of the low density and high hardness. Color aluminum is a newly emerging material in the field of doors and windows. Compared with steel, the biggest advantage is unparalleled firmness, varied colors and non-toxic for which steel has always been blamed. Therefore, it is widely used in areas such as doors and windows, sunroom and balcony seal. Color coated aluminum coil has become one of the most popular decorative material which is environmentally-friendly, durable and aesthetic. As a decorative material, it has the following unparalleled advantages: uniform color, bright and clean, strong adhesion, durability, anti-acid and anti-alkali, corrosion resistance, wind and weather resistance, decay and abrasion resistance and ultraviolet proof. Products categories: polyester coated aluminum coil (PE) and perfluorocarbon coated aluminum coil (PVDF).

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- The inherent properties and characteristics of aluminum coils play a vital role in improving recyclability in the construction industry. To begin with, aluminum is a material that can be recycled repeatedly without losing its quality or physical properties, making aluminum coils an eco-friendly and sustainable option for construction projects. The recyclability of aluminum coils aids in reducing the environmental impact associated with the construction industry. By opting for aluminum coils, construction companies can contribute to the preservation of natural resources and the reduction of energy consumption. Recycling aluminum requires much less energy compared to producing it from raw materials, resulting in a significant decrease in greenhouse gas emissions and carbon footprint. Furthermore, the use of aluminum coils in construction simplifies the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Moreover, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, thereby minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be effortlessly collected, recycled, and reintroduced into the manufacturing cycle, completing the material's lifecycle. In conclusion, aluminum coils play a significant role in enhancing recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Aluminum coils play a crucial role in the production of cans. They are commonly utilized to manufacture thin aluminum sheets, which are subsequently molded into cans. To achieve the desired thickness and width for can production, the coils undergo a series of steps, including rolling, annealing, and slitting. Once the aluminum sheets are prepared, they are cut into suitable sizes and shaped into the familiar cylindrical can form. Aluminum is a favored material for can manufacturing because of its lightweight, durable, and corrosion-resistant properties. Moreover, it serves as a protective barrier against light, oxygen, and moisture, thus ensuring the preservation of the contents' quality and shelf life. In summary, aluminum coils are an indispensable element in the can manufacturing process and play a significant role in the packaging industry.

- Q: What is the maximum yield strength of aluminum coils?

- The specific alloy and temper of aluminum significantly influence the maximum yield strength of aluminum coils. Typically, aluminum coils exhibit a yield strength between 10,000 and 40,000 psi. It must be emphasized that diverse properties and, consequently, varying maximum yield strengths are observed in different aluminum alloys and tempers. Furthermore, the thickness and width of aluminum coils have an impact on their maximum yield strength as well. Thus, to ascertain the precise maximum yield strength of aluminum coils, it is advisable to refer to the manufacturer's specifications or standards pertaining to the specific alloy and temper of the coils.

- Q: Can aluminum coils be used in food processing or packaging?

- Food processing or packaging can use aluminum coils. Aluminum is commonly used in the food industry because of its lightweight, non-toxic, and corrosion-resistant properties. These qualities make it an ideal material for food processing and packaging. Aluminum coils are capable of producing various food packaging products like cans, lids, foils, and trays. They create a protective barrier against oxygen, moisture, and light, which help maintain the freshness and quality of food items. Moreover, aluminum coils are malleable, easy to shape, and seal, resulting in efficient and effective packaging solutions. In general, aluminum coils are highly favored for food processing and packaging due to their versatility, durability, and safety.

- Q: What are the storage life and shelf life of aluminum coils?

- The storage life and shelf life of aluminum coils can vary depending on various factors such as the storage conditions and the specific type of aluminum alloy used. Generally, aluminum coils have a relatively long storage life and shelf life. In terms of storage life, aluminum coils can be stored for an extended period of time without significant degradation in their quality or performance. However, it is important to store them in a dry and well-ventilated area to prevent corrosion. Moisture can cause oxidation and corrosion, which can affect the integrity and durability of the aluminum coils. As for the shelf life, aluminum coils can remain in good condition and retain their functional properties for an extended period of time when stored properly. The exact shelf life will depend on the specific application and the intended use of the aluminum coils. To ensure the longevity of aluminum coils, it is recommended to follow the manufacturer's guidelines for storage and handling. Additionally, regular inspections and maintenance can help identify any signs of corrosion or damage and take appropriate measures to prevent further deterioration.

- Q: Explain how the temperature affects aluminum coil properties and behavior.

- <p>The relationship between aluminum coil and temperature is significant as temperature influences the coil's physical properties and performance. At lower temperatures, aluminum coils become more brittle and susceptible to cracking or breaking. As the temperature increases, aluminum's ductility improves, allowing it to be more easily shaped and formed. However, excessive heat can also lead to deformation and loss of strength. The thermal conductivity of aluminum is high, meaning it conducts heat well, which is useful in applications requiring heat transfer. Additionally, the electrical conductivity of aluminum is affected by temperature; as temperature rises, resistance increases, which can impact applications where electrical conductivity is critical.</p>

- Q: Foshan where there are high-quality aluminum and aluminum rolls for sale?

- If you know where to use, or what are the requirements of the words I can occasionally recommend you manufacturers give you, because I am in this industry!

- Q: Can aluminum coils be recycled multiple times?

- Yes, aluminum coils can be recycled multiple times. Aluminum is a highly recyclable material, and the recycling process does not degrade its quality. This means that aluminum coils can be melted down and reformed into new coils multiple times without any loss in their performance or properties. Recycling aluminum not only helps to conserve natural resources but also saves energy compared to producing new aluminum from raw materials. Therefore, aluminum coils are a sustainable and environmentally friendly choice that can be recycled multiple times.

Send your message to us

6063 Aluminum Coil Manufacture Five Bar Pattern 5052 4mm Aluminum Checkered Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords