All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are aluminum coils used in the production of aluminum honeycomb core panels?

Aluminum coils are used in the production of aluminum honeycomb core panels as they are processed and shaped into thin sheets. These sheets are then expanded and bonded together to create the honeycomb structure, which provides strength and rigidity to the panels. The coils are a crucial raw material in the manufacturing process, allowing for the efficient production of lightweight yet durable aluminum honeycomb core panels.

What is the process of slitting aluminum coils?

The process of slitting aluminum coils involves unwinding a large coil of aluminum and cutting it into narrower strips. This is typically done using a specialized machine called a slitter, which has multiple circular blades that can cut through the aluminum. The coil is fed through the slitter, and the blades make precise cuts along the length of the coil to create the desired strip width. The slit strips are then rewound onto separate coils or packaged for further processing or distribution.

How do you protect aluminum coils from abrasion during transit and handling?

To protect aluminum coils from abrasion during transit and handling, various measures can be taken. Firstly, using protective materials such as rubber or foam padding can be wrapped around the coils to cushion them and minimize contact with hard surfaces. Additionally, placing the coils in sturdy packaging, such as crates or boxes, can provide an extra layer of protection. Securing the packaging with straps or adhesive tape can prevent any movement or shifting during transportation. Moreover, training the personnel involved in handling the coils to be careful and cautious can greatly reduce the risk of abrasion.

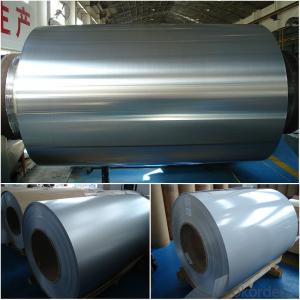

Wholesale Aluminum Coils from supplier in Australia

Whether you are in the construction, automotive, packaging, or any other industry that requires Aluminum Coils, we have the knowledge and resources to cater to your specific requirements. Our team of experts can assist you in selecting the right grade, thickness, and finish for your application, ensuring optimal performance and durability.

We take pride in our commitment to delivering high-quality Aluminum Coils that meet international standards. Our products are sourced from trusted manufacturers and undergo rigorous quality control checks to ensure consistency and reliability. Additionally, we offer competitive pricing and flexible delivery options to suit your project timelines.

In addition to our sales services, we also provide comprehensive technical support to assist you at every stage of your project. Whether you need assistance with design specifications, material selection, or troubleshooting, our dedicated team is always ready to help. We understand the importance of timely and accurate information, and we strive to provide prompt responses and solutions to your queries.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to stay updated with the latest industry trends and innovations, ensuring that we can offer you the most advanced Aluminum Coils solutions available in the market.

At our company, customer satisfaction is our top priority. We are committed to building long-term relationships with our clients by providing exceptional service and support. Whether you are a small business or a large corporation, we treat every customer with the same level of professionalism and dedication.

If you are in need of Aluminum Coils in Australia, we invite you to partner with us. Contact us today to discuss your requirements and experience the difference of working with a leading supplier in the industry.

We take pride in our commitment to delivering high-quality Aluminum Coils that meet international standards. Our products are sourced from trusted manufacturers and undergo rigorous quality control checks to ensure consistency and reliability. Additionally, we offer competitive pricing and flexible delivery options to suit your project timelines.

In addition to our sales services, we also provide comprehensive technical support to assist you at every stage of your project. Whether you need assistance with design specifications, material selection, or troubleshooting, our dedicated team is always ready to help. We understand the importance of timely and accurate information, and we strive to provide prompt responses and solutions to your queries.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to stay updated with the latest industry trends and innovations, ensuring that we can offer you the most advanced Aluminum Coils solutions available in the market.

At our company, customer satisfaction is our top priority. We are committed to building long-term relationships with our clients by providing exceptional service and support. Whether you are a small business or a large corporation, we treat every customer with the same level of professionalism and dedication.

If you are in need of Aluminum Coils in Australia, we invite you to partner with us. Contact us today to discuss your requirements and experience the difference of working with a leading supplier in the industry.