All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

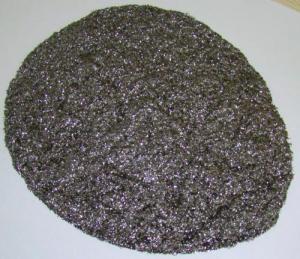

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are refractory materials chosen for lining cement kilns and other high-temperature equipment?

Refractory materials are chosen for lining cement kilns and other high-temperature equipment based on their ability to withstand extreme temperatures, resist chemical reactions, and have good thermal conductivity. Factors such as the type of fuel used, the operating temperature, the presence of corrosive substances, and the desired service life are considered when selecting refractory materials. Additionally, the material's mechanical strength, thermal shock resistance, and ease of installation are also taken into account for optimal performance and cost-effectiveness.

What is zirconia, and how is it used in refractories?

Zirconia is a white, crystalline oxide of the metal zirconium, known for its high melting point and excellent thermal and chemical stability. It is commonly used in refractories, which are materials designed to withstand high temperatures and harsh environments. In refractories, zirconia is used as a key component due to its ability to enhance the mechanical strength, thermal shock resistance, and corrosion resistance of the material. Its refractory properties make it ideal for lining furnaces, kilns, and other high-temperature industrial applications.

How is carbon processed and shaped for refractory applications?

Carbon is processed and shaped for refractory applications through a series of steps. Firstly, raw carbon materials such as petroleum coke or coal tar pitch are selected and crushed into smaller particles. These particles are then mixed with binders and additives to form a carbon paste or slurry. This paste is then shaped into the desired form using various techniques like extrusion, molding, or casting. After shaping, the carbon products are subjected to a heating process called carbonization, which removes volatile components and strengthens the structure. Finally, the carbon products undergo a graphitization process, where they are heated at high temperatures to transform the carbon into a more crystalline structure, improving its refractory properties.

What are the thermal properties of refractory raw materials?

The thermal properties of refractory raw materials refer to their ability to withstand high temperatures without undergoing significant changes in their physical or chemical properties. These materials typically have a high melting point, low thermal conductivity, and excellent thermal shock resistance. They also exhibit minimal expansion or contraction when subjected to extreme temperature fluctuations. These properties make refractory raw materials suitable for applications in industries such as metallurgy, glassmaking, and ceramics manufacturing, where they are used to line furnaces, kilns, and other high-temperature environments.

Wholesale Raw Materials For Refractory from supplier in Australia

Whether you are in the mining, construction, manufacturing, or energy industry, we are here to support your refractory needs. Trust us to provide you with high-quality raw materials for furnace linings, kiln furniture, and thermal insulation.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive prices and reliable procurement services. Our team of experts is dedicated to meeting your specific requirements and ensuring that you receive the best products and services.

We understand the unique challenges and regulations in the Australian market and have tailored our operations to meet these demands. With our extensive experience and knowledge, we have built strong relationships with local manufacturers to ensure that we can provide you with the best materials at competitive prices.

Our technical support team is always ready to assist you with any inquiries or project-specific requirements. We are committed to providing you with the necessary support and expertise to ensure the success of your refractory projects.

Choose us as your supplier of raw materials for refractory in Australia and experience the benefits of our comprehensive procurement services, wide product range, competitive prices, and extensive market experience. Contact us today to discuss your requirements and let us help you find the best solutions for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive prices and reliable procurement services. Our team of experts is dedicated to meeting your specific requirements and ensuring that you receive the best products and services.

We understand the unique challenges and regulations in the Australian market and have tailored our operations to meet these demands. With our extensive experience and knowledge, we have built strong relationships with local manufacturers to ensure that we can provide you with the best materials at competitive prices.

Our technical support team is always ready to assist you with any inquiries or project-specific requirements. We are committed to providing you with the necessary support and expertise to ensure the success of your refractory projects.

Choose us as your supplier of raw materials for refractory in Australia and experience the benefits of our comprehensive procurement services, wide product range, competitive prices, and extensive market experience. Contact us today to discuss your requirements and let us help you find the best solutions for your projects.

Hot Search

- Monolithic Refractories in Lithuania

- Ceramic Fiber Products in Zimbabwe

- Refractory Bricks in Niger

- Raw Materials For Refractory in Malaysia

- Raw Materials For Refractory in Denmark

- Refractory Bricks in Cyprus

- Ceramic Fiber Products in Tunisia

- Monolithic Refractories in Seychelles

- Refractory Bricks in Angola

- Ceramic Fiber Products in Indonesia