All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining copper melting furnaces?

Yes, monolithic refractories can be used for lining copper melting furnaces.

What are the main factors affecting the permeability of monolithic refractories?

The main factors affecting the permeability of monolithic refractories include the particle size distribution and packing arrangement, the presence of binders and additives, the curing and firing conditions, and the porosity of the refractory material.

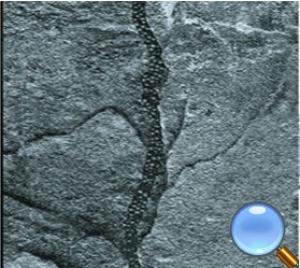

Are monolithic refractories resistant to spalling?

Yes, monolithic refractories are generally resistant to spalling. Spalling refers to the breaking off or flaking of the refractory material due to thermal stresses. Monolithic refractories, which are composed of a single, continuous material, offer better resistance to spalling compared to traditional refractory bricks or tiles. They can withstand high temperatures and thermal cycling without easily disintegrating, making them a reliable choice for applications where spalling is a concern.

What are the challenges in using monolithic refractories in large-scale applications?

One of the main challenges in using monolithic refractories in large-scale applications is their limited structural strength. Monolithic refractories are typically composed of a single material, which makes them more susceptible to cracking and damage under high temperatures and mechanical stress. Additionally, their installation process can be complex and time-consuming, requiring skilled personnel and specialized equipment. Another challenge is their susceptibility to chemical attack and erosion, as they may not provide the same level of resistance as traditional brick refractories. Therefore, careful design and regular maintenance are necessary to ensure their longevity and optimal performance in large-scale applications.

What are the best practices for installing monolithic refractories?

Some of the best practices for installing monolithic refractories include proper surface preparation, ensuring correct mixing and consistency of the refractory material, using appropriate installation techniques such as vibration or ramming, allowing sufficient curing and drying time, and conducting thorough quality control checks throughout the installation process. Additionally, following manufacturer guidelines and seeking expert advice can further enhance the installation of monolithic refractories.

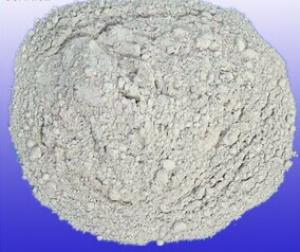

Wholesale Monolithic Refractories from supplier in Seychelles

From basic refractory materials to advanced specialized products, we have a wide selection of monolithic refractories to meet your specific requirements. Our product range includes castables, gunning mixes, ramming mixes, and plastic refractories, among others. We ensure that our products are of the highest quality and are sourced from reliable manufacturers.

In addition to providing top-notch products, we also offer sales, quotation, and technical support services. Our team of experts is available to assist you in selecting the right refractory materials for your application and provide guidance on installation and maintenance. We understand the importance of timely and accurate quotations, and our dedicated sales team will ensure that you receive competitive pricing for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your monolithic refractories procurement needs in the Seychelles. CNBM has a strong presence in the global market and has established itself as a trusted supplier of construction materials. This affiliation allows us to leverage CNBM's extensive network and expertise to deliver high-quality products and services to our customers in the Seychelles.

Our experience in the Seychelles market sets us apart from other suppliers. We have developed strong relationships with local customers and have a deep understanding of the unique challenges and requirements of projects in the Seychelles. Our team can provide valuable insights and expertise to help you make informed decisions and ensure the success of your projects.

Whether you are involved in construction, steel, cement, or other industries requiring monolithic refractories, we are your reliable partner in the Seychelles. Contact us today to discuss your specific needs and let us assist you in sourcing the best monolithic refractories for your projects.

In addition to providing top-notch products, we also offer sales, quotation, and technical support services. Our team of experts is available to assist you in selecting the right refractory materials for your application and provide guidance on installation and maintenance. We understand the importance of timely and accurate quotations, and our dedicated sales team will ensure that you receive competitive pricing for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your monolithic refractories procurement needs in the Seychelles. CNBM has a strong presence in the global market and has established itself as a trusted supplier of construction materials. This affiliation allows us to leverage CNBM's extensive network and expertise to deliver high-quality products and services to our customers in the Seychelles.

Our experience in the Seychelles market sets us apart from other suppliers. We have developed strong relationships with local customers and have a deep understanding of the unique challenges and requirements of projects in the Seychelles. Our team can provide valuable insights and expertise to help you make informed decisions and ensure the success of your projects.

Whether you are involved in construction, steel, cement, or other industries requiring monolithic refractories, we are your reliable partner in the Seychelles. Contact us today to discuss your specific needs and let us assist you in sourcing the best monolithic refractories for your projects.

Hot Search

- Monolithic Refractories in Sri Lanka

- Ceramic Fiber Products in Dominica

- Refractory Bricks in Mauritius

- Raw Materials For Refractory in Georgia

- Ceramic Fiber Products in Malaysia

- Refractory Bricks in Papua New Guinea

- Monolithic Refractories in Thailand

- Refractory Bricks in Monaco

- Monolithic Refractories in Malta

- Refractory Bricks in Yemen