All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

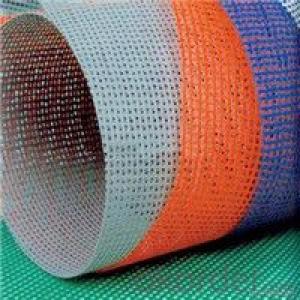

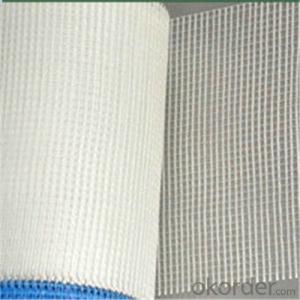

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

How does fiberglass perform in high-traffic areas?

Fiberglass performs exceptionally well in high-traffic areas. It is highly durable, resistant to wear and tear, and can withstand heavy foot traffic without showing signs of damage or degradation. Additionally, it has a smooth and non-porous surface, making it easy to clean and maintain in busy areas. Its strength and longevity make it an ideal choice for high-traffic environments such as commercial buildings, schools, airports, and public spaces.

Can fiberglass supply be used for renewable energy systems?

Yes, fiberglass supply can be used for renewable energy systems. Fiberglass is often used in the construction of wind turbine blades, as it is lightweight, durable, and can withstand harsh weather conditions. Additionally, fiberglass can be used in the manufacturing of solar panels, where it acts as a protective layer or backing material.

How do you repair a fiberglass RV roof?

To repair a fiberglass RV roof, you will first need to clean the damaged area thoroughly by removing any dirt, debris, or loose material. Next, sand the damaged area using fine-grit sandpaper to create a smooth surface for the repair. Then, apply a specialized fiberglass repair kit or epoxy resin designed for RV roofs, following the manufacturer's instructions carefully. Make sure to apply multiple layers, allowing each layer to dry completely before adding the next one. Once the repair is complete, you can sand and paint the area to match the rest of the roof, if desired.

What are the different fabrication methods for fiberglass?

There are several different fabrication methods for fiberglass, including hand lay-up, spray-up, filament winding, pultrusion, and vacuum bagging. Each method involves different techniques and tools to shape and mold the fiberglass material into the desired form.

Can fiberglass be made sound-absorbing?

Yes, fiberglass can be made sound-absorbing. It is commonly used in the construction industry as a sound-absorbing material due to its ability to trap and dampen sound waves. This is achieved by using fiberglass with specific acoustic properties, such as density and thickness, and incorporating it into products like acoustic panels or insulation.

Wholesale Fiberglass Supply from supplier in Seychelles

With our Fiberglass Supply solutions, you can expect high-quality products that are durable, reliable, and cost-effective. We understand the importance of using the right materials for your projects, and that's why we only offer products from reputable manufacturers. Whether you are working on a small DIY project or a large-scale industrial project, we have the right Fiberglass Supply products to meet your needs.

Our team of experts is always ready to provide you with professional advice and support. From product selection to technical assistance, we are here to help you every step of the way. We believe in building long-term relationships with our customers, and that's why we strive to exceed your expectations with our exceptional customer service.

At Fiberglass Supply supplier in Seychelles, we value your time and budget. We offer competitive pricing and flexible payment options to ensure that you get the best value for your money. Our efficient logistics network enables us to deliver your orders in a timely manner, so you can focus on your projects without any delays.

Whether you are in the construction, marine, automotive, or any other industry that requires Fiberglass Supply products, we have the solutions for you. Contact us today to discuss your requirements and let us provide you with the best Fiberglass Supply products in Seychelles.

Our team of experts is always ready to provide you with professional advice and support. From product selection to technical assistance, we are here to help you every step of the way. We believe in building long-term relationships with our customers, and that's why we strive to exceed your expectations with our exceptional customer service.

At Fiberglass Supply supplier in Seychelles, we value your time and budget. We offer competitive pricing and flexible payment options to ensure that you get the best value for your money. Our efficient logistics network enables us to deliver your orders in a timely manner, so you can focus on your projects without any delays.

Whether you are in the construction, marine, automotive, or any other industry that requires Fiberglass Supply products, we have the solutions for you. Contact us today to discuss your requirements and let us provide you with the best Fiberglass Supply products in Seychelles.