All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

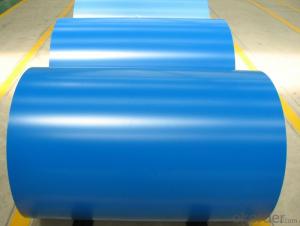

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the advancements in aluminum coil technology for use in electrical conductors?

Some advancements in aluminum coil technology for use in electrical conductors include improvements in alloy composition, manufacturing processes, and insulation techniques. These advancements have resulted in aluminum coils with higher conductivity, better mechanical strength, and increased resistance to corrosion. Additionally, advancements in insulation materials have enabled the use of aluminum coils in higher voltage applications. Overall, these advancements have made aluminum coils a more efficient and reliable option for electrical conductors.

What is the role of aluminum coils in the production of electrical conductors?

Aluminum coils play a crucial role in the production of electrical conductors as they serve as the primary material used for creating the conducting wires. The aluminum coils are typically processed and drawn into fine wires that possess excellent electrical conductivity properties. These wires are then used in various electrical applications such as power transmission, wiring systems, and electrical appliances. Due to its lightweight nature and high electrical conductivity, aluminum is preferred for manufacturing electrical conductors, making the aluminum coils an essential component in the production process.

What is the difference between hot-rolled and cold-rolled aluminum coils?

The main difference between hot-rolled and cold-rolled aluminum coils lies in the manufacturing process. Hot-rolled aluminum coils are produced by heating the aluminum billets to high temperatures and then rolling them through a series of rollers, resulting in a thicker and less precise product. On the other hand, cold-rolled aluminum coils are processed at lower temperatures, which allows for more precise dimensions and a smoother surface finish. This makes cold-rolled coils ideal for applications that require tight tolerances and a high-quality appearance.

What is the cost difference between aluminum and steel coils?

The cost difference between aluminum and steel coils can vary depending on various factors such as market conditions, supply and demand, and quality of the materials. Generally, aluminum coils tend to be more expensive than steel coils due to the higher cost of the raw material and its processing. However, it is important to consider other factors such as durability, weight, and specific application requirements before making a decision based solely on cost.

Wholesale Aluminum Coils from supplier in Seychelles

Our team of experts is dedicated to understanding your specific requirements and providing you with tailored solutions. Whether you need Aluminum Coils for construction, manufacturing, or any other industry, we have the expertise to meet your needs.

We offer a wide range of Aluminum Coil options, including different sizes, grades, and finishes. Our coils are sourced from reputable manufacturers and undergo strict quality control measures to ensure their reliability and durability.

In addition to supplying Aluminum Coils, we also provide comprehensive services to support your procurement process. Our sales team is available to assist you in selecting the right products for your project and providing competitive quotes. We also offer technical support, helping you with any queries or issues you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and network to provide seamless procurement solutions. Our strong relationships with suppliers and extensive market experience in the Seychelles enable us to offer valuable insights and expertise to enhance your projects.

Whether you are a contractor, builder, manufacturer, or any other industry professional in the Seychelles, we are here to support your Aluminum Coil needs. Contact us today to discuss your requirements and let us provide you with the best solutions.

We offer a wide range of Aluminum Coil options, including different sizes, grades, and finishes. Our coils are sourced from reputable manufacturers and undergo strict quality control measures to ensure their reliability and durability.

In addition to supplying Aluminum Coils, we also provide comprehensive services to support your procurement process. Our sales team is available to assist you in selecting the right products for your project and providing competitive quotes. We also offer technical support, helping you with any queries or issues you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and network to provide seamless procurement solutions. Our strong relationships with suppliers and extensive market experience in the Seychelles enable us to offer valuable insights and expertise to enhance your projects.

Whether you are a contractor, builder, manufacturer, or any other industry professional in the Seychelles, we are here to support your Aluminum Coil needs. Contact us today to discuss your requirements and let us provide you with the best solutions.