Black Aluminum Diamond Plate Sheets - Good Price Aluminum Checkered Sheet in Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION'S Aluminum checkered plate is very best-selling in the industrial construction field and decoration field, etc.

There are many different alloy nubmer: 6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 5052,5754,6061,6063,8011, etc.

The temper is include H44, H24, F ,O, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

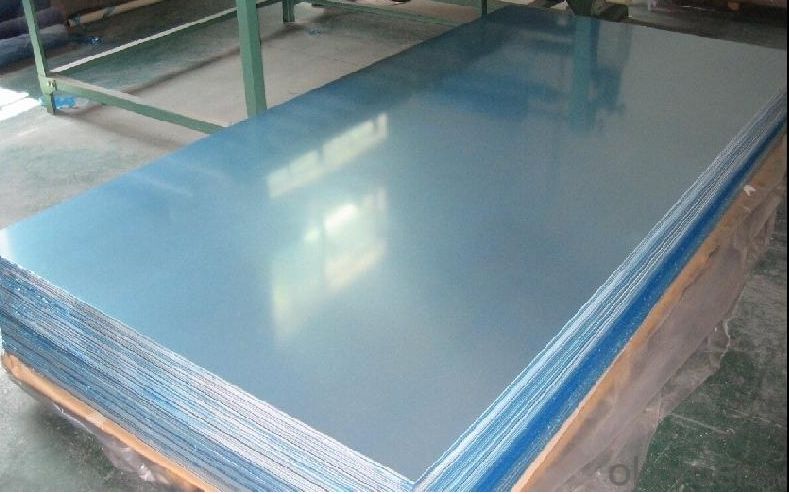

3. Image.

4. Product detailed sizes:

1000mm*2000mm,2000mm*2000mm, 800mm*800mm,etc.500MM*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 400mm to 2500mm, etc.

What is the length range:

---It is from 800mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 12 tons/each size.

How many tons did you export in one year?

---Normally it is around 20000 tons totally.

Where is your client from?

---Normally it is from Pakistan,Saudi Arabia, BANGLADESH,PAKISTAN,FIJI, England,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium plate and alut, aluminum casting coil, etc.

- Q: 2mm aluminum welding with oxygen welding or argon arc welding good?

- Before welding need cleaning with acetone wire and base metal surface oil and oxide layer, according to welding tungsten diameter, filler wire diameter selection of appropriate welding parameters (base current, peak current, pulse width, pulse duration, pulse frequency, duty ratio, etc.).Oxygen acetylene (or oxygen propane) flame welding, flame welding due to large heating area, directly lead to weld coarse grains, degree of weld oxidation is lower than that of AC TIG welding effect. The weld strength and mechanical properties are lower.

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- It seems to me like food that comes out of a can has a slight metallic taste to it. Even though there's a plastic lining it still tastes like it contains trace amounts of aluminum for some reason.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Aluminum sheets are indeed suitable for food preparation surfaces. They are a lightweight and durable option extensively utilized in the food industry. Being non-toxic and non-reactive, aluminum does not pose any risk of releasing harmful chemicals upon contact with food. Moreover, aluminum sheets are highly convenient to clean and maintain, making them a preferred choice for both commercial and home kitchens. Furthermore, aluminum boasts excellent heat conductivity, ensuring even cooking and baking. Nevertheless, it is worth mentioning that aluminum may react with acidic or salty foods, resulting in a metallic taste. To prevent this, it is advisable to place a layer of parchment paper or a silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: Can aluminum sheet be used for food packaging?

- Yes, aluminum sheet can be used for food packaging.

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- There are several methods of surface protection for outdoor aluminum sheets. One common method is painting the surface with a protective coating, such as a weather-resistant paint or powder coating. Another method is anodizing, which involves creating a durable oxide layer on the surface of the aluminum. Additionally, applying a clear protective film or using a protective sealant can also help protect the aluminum sheet from outdoor elements.

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: How do you ensure the flatness of large aluminum sheets?

- To ensure the flatness of large aluminum sheets, there are several key steps that can be taken: 1. Material selection: Start by choosing high-quality aluminum sheets that are specifically manufactured for flatness. These sheets should have consistent thickness and minimal internal stress to minimize the chances of warping. 2. Proper storage: Store the aluminum sheets in a controlled environment to avoid exposure to extreme temperature fluctuations or humidity. This will help prevent any potential expansion or contraction of the metal, which can lead to warping. 3. Handling and transportation: When moving or transporting the aluminum sheets, ensure that they are supported evenly to prevent any bending or flexing. Use appropriate lifting and handling equipment to avoid excessive strain on the sheets. 4. Machining and processing: During the machining and processing steps, it is crucial to use proper techniques and equipment to maintain flatness. Employ precision machinery that is capable of handling large sheets and has features to minimize distortion or bending during cutting, drilling, or forming processes. 5. Heat treatment: If necessary, heat treatment can be employed to relieve any residual stress in the aluminum sheets. Thermal stress relief techniques, such as annealing, can help reduce internal stress and improve flatness. 6. Quality control: Implement a rigorous quality control process to ensure the flatness of the aluminum sheets. This can include regular inspections using precision measuring instruments, such as straightedges or laser scanners, to detect any deviations from flatness. If any issues are identified, corrective actions can be taken promptly. By following these steps, manufacturers can ensure the flatness of large aluminum sheets, which is crucial for various industries such as aerospace, automotive, construction, and manufacturing.

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- Best Epoxy For Aluminum

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: What precautions should be taken while handling aluminum sheets to ensure safety?

- <p>When working with aluminum sheets, it's important to take certain safety measures. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against sharp edges and metal dust. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper tools designed for metal work to prevent accidents. Keep the work area clean and free from clutter to minimize trip hazards. Be cautious of electrical hazards if using power tools, and ensure all tools are in good working order. Finally, be aware of the fire hazard potential of aluminum, especially when cutting or welding, and have fire extinguishers readily available.</p>

Send your message to us

Black Aluminum Diamond Plate Sheets - Good Price Aluminum Checkered Sheet in Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords