3 16 Diamond Plate Aluminum Sheets C.C 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets C.C 3XXX Description

Aluminum Sheets C.C 3XXX is cut from aluminum coils 3xxx. Aluminum Sheets C.C 3XXX has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets C.C 3XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets C.C 3XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

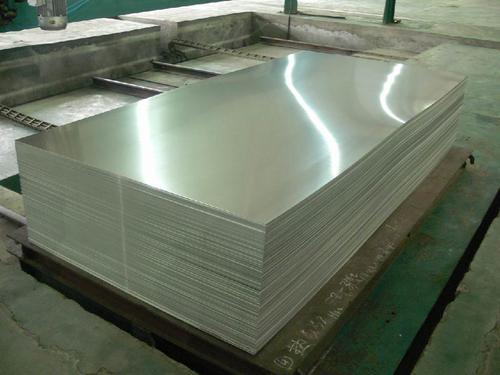

3.Aluminum Sheets C.C 3XXX Images

4.Aluminum Sheets C.C 3XXX Specification

| Alloy | AA3xxx (AA3003,AA3004,AA3005,AA3105 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ ofAluminum Sheets C.C 3XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum Sheets C.C 3XXX products.

B.When will you deliver the products?

The Aluminum Sheets C.C 3XXX will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The surface finish of aluminum sheet can significantly impact its optical properties. A smooth surface finish on aluminum sheet results in better light reflection and less scattering, leading to higher reflectivity. This means that more light is reflected off the surface, making the aluminum sheet appear brighter and more reflective. On the other hand, a rough or textured surface finish on aluminum sheet can cause light to scatter in different directions, reducing reflectivity. This can result in a duller and less reflective appearance. Additionally, the surface finish can affect the appearance of any coatings or films applied to the aluminum sheet. A smooth surface finish allows for better adhesion and uniformity of coatings, enhancing their optical properties. In summary, a smooth surface finish on aluminum sheet enhances its optical properties by increasing reflectivity and reducing scattering, resulting in a brighter and more reflective appearance.

- Q: What is the tensile strength of aluminum sheets?

- The tensile strength of aluminum sheets can vary depending on the specific alloy and temper of the material. However, on average, aluminum sheets typically have a tensile strength ranging from 10,000 to 45,000 pounds per square inch (psi). It is important to note that different grades and thicknesses of aluminum sheets will have different tensile strength values. Additionally, factors such as heat treatment, processing, and alloy composition can also affect the tensile strength of aluminum sheets. Therefore, it is necessary to consult the manufacturer's specifications or perform specific tests to determine the precise tensile strength of a particular aluminum sheet.

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a versatile material that offers several advantages for facade applications. It is lightweight, durable, and corrosion-resistant, making it suitable for various weather conditions. Aluminum sheets can be easily fabricated and installed, offering flexibility in design and allowing for intricate and complex facades. Additionally, aluminum can be finished in a variety of ways, including powder coating, anodizing, or painting, to enhance its appearance and provide the desired aesthetic appeal. Overall, the use of aluminum sheets for architectural facades provides architects and designers with a wide range of options to create visually appealing and long-lasting building exteriors.

- Q: What is the thermal conductivity of aluminum sheets?

- The thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin.

- Q: What are the different methods of punching aluminum sheets?

- There are several different methods used for punching aluminum sheets, each with its own advantages and limitations. Here are some of the most common methods: 1. Manual Punching: This is the most basic method, where a handheld punch tool is used to manually punch holes or shapes into the aluminum sheet. It is suitable for small-scale projects and simple designs, but it can be time-consuming and less precise compared to other methods. 2. Mechanical Punching: Mechanical punching machines utilize a mechanical press with a punch and die set to punch holes or shapes into the aluminum sheet. These machines are capable of higher production rates and offer better accuracy and repeatability. This method is suitable for medium to large-scale projects. 3. CNC Punching: Computer Numerical Control (CNC) punching machines use computer programming to control the movement of the punch and die set. This method allows for the punching of complex shapes, patterns, and multiple holes in a single operation. CNC punching offers high precision, efficiency, and versatility, making it popular in industrial settings. 4. Laser Punching: Laser punching combines laser cutting and punching technologies. A high-powered laser beam is used to heat and soften the aluminum sheet, followed by a mechanical punch that creates the desired hole or shape. Laser punching offers high precision, speed, and the ability to work with various materials and thicknesses. It is commonly used in the automotive and aerospace industries. 5. Waterjet Punching: Waterjet punching involves using a high-pressure stream of water mixed with abrasive materials to cut through the aluminum sheet. This method is ideal for cutting complex shapes and thick materials. It offers high precision, minimal material distortion, and the ability to work with a wide range of materials. The choice of punching method depends on factors such as the complexity of the design, required precision, production volume, and budget. It is important to consider these factors and consult with professionals to determine the most suitable punching method for a specific aluminum sheet application.

- Q: Can aluminum sheets be used for electrical busbars?

- Yes, aluminum sheets can be used for electrical busbars. Aluminum is a commonly used material for busbars due to its excellent electrical conductivity, lightweight nature, and cost-effectiveness. However, it is important to consider factors such as current carrying capacity, temperature rise, and mechanical strength when selecting aluminum sheets for busbar applications.

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- 4Al + 6Na2(C2O4) ---- 2Al2(C2O4)3 + 6KMnO4 ---- 3K2(C2O4) Aluminum oxalate and potassium permanganate are at a 1:3 ratio.... Moles of KMnO4 C = 0.1098 mol/L v = 42.12 ml = 0.04212 L C = n/v n= CV = 0.004624776 mols Therefore moles of aluminum oxylate = 0.001541592 mol = moles of aluminum m= 26.98 g/mol * moles mass of aluminum in oxylate = 0.04159215 g % of initial sample = mass of aluminum / mass of ore = 17.24% aluminum in ore sample Perhaps check my math but the method is for sure correct.

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- If this is your first bow, I'd say go aluminum. Get the Platinum Plus from Easton, much cheaper and a hell of a lot better build than carbon arrows twice its price. The key with aluminum is to choose shafts with thick walls. When you look at the shaft sizes, you have a 4 digit number. The first 2 digits represents the outer diameter of the shaft, while the second 2 digits represents the wall thickness. With Plats, you want to get something with a 16 wall thickness. That's 16/1000, so 1516 or 1716 etc. The size/stiffness of these shafts will depend on 2 major factors, and 1 not so major one. The major factors are drawlength and draw weight at that drawlength. The one other factor is the bow design and material. Certain newer top end limbs will be so fast that they need stiffer arrows compared to older bows of the same drawweight. Now, carbon shafts, carbon shafts break yes, but it's your responsibility to make sure before you shoot to check for micro cracks. To do that, you bend the arrow and turn the shaft while listening for cracking noises. Well built carbon shafts will last a very long time, but well built carbon arrows are also at least 3 times more expensive than the Plats. Some durable arrows include the Gold Tip, and the Carbon Express. Not all carbon arrows are built to be durable mind you. Some are built for speed sacrificing durability. So, my vote is get yourself a set of Platinums, these shafts, while cheap had been the world record holder for a rather long time at 18m and 25m.

Send your message to us

3 16 Diamond Plate Aluminum Sheets C.C 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords