POLISHED ALUMINIUM PLATES FOR MOLD PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description:Polished aluminium sheets 6061 for mold production

2. Our Strength:

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

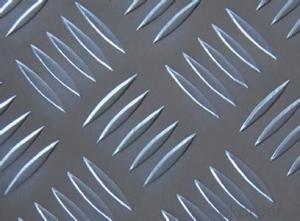

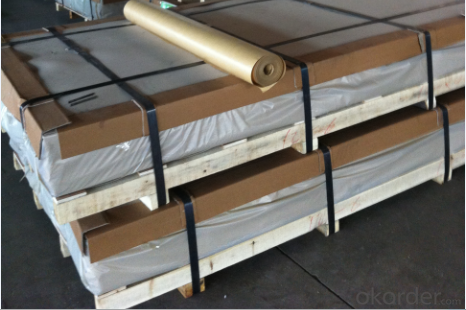

3. Image:

4. Common Specification

1000mm*2000mm, 1500*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a safe and commonly used material for food packaging and cooking utensils due to its non-toxic properties, resistance to corrosion, and ability to maintain food quality and freshness.

- Q: Can 101 aluminum sheets be bent or formed into different shapes?

- Certainly! It is indeed possible to bend or shape 101 aluminum sheets into various forms. Aluminum possesses high malleability, meaning it can be shaped effortlessly without any risk of breaking or cracking. The specific grade of aluminum, such as 101, signifies the alloy composition and might possess specific properties that make it more suitable for bending and shaping. Nevertheless, the capacity to bend or shape aluminum sheets also relies on their thickness; thicker sheets may necessitate greater force and specialized equipment. In conclusion, with the correct tools and techniques, it is feasible to bend or shape 101 aluminum sheets into diverse shapes to fulfill specific requirements.

- Q: Which kind of glue is best for bonding aluminum sheets?

- 502 or universal glue

- Q: Are aluminum sheets suitable for water storage applications?

- Indeed, water storage applications can make use of aluminum sheets. Aluminum, being a lightweight and resilient substance, exhibits remarkable resistance towards rust and corrosion. Moreover, it possesses impermeability to water, air, and light, thereby rendering it an optimal selection for water storage. Furthermore, aluminum sheets can effortlessly be molded into diverse dimensions and configurations, enabling the creation of personalized water storage solutions.

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, including welding, riveting, adhesive bonding, and mechanical fastening. Welding involves melting and fusing the aluminum sheets together using heat, while riveting involves using metal fasteners to hold the sheets together. Adhesive bonding uses specialized adhesives to create a strong bond between the sheets, and mechanical fastening involves using screws, bolts, or other mechanical devices to secure the sheets together.

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- The density of gold is higher than the density of aluminum, so a kg of gold would take up less space than a kg of aluminum. But to answer your homework, you should look up the specific gravities of each of these metals, and figure out the volume of a kg of each....

- Q: Are 101 aluminum sheets suitable for chemical processing environments?

- Chemical processing environments can utilize 101 aluminum sheets effectively. These sheets are made from a commercially pure aluminum alloy known as 101 aluminum, which boasts commendable resistance to corrosion and exceptional weldability. They find extensive application in settings demanding high corrosion resistance, such as chemical processing plants. Moreover, the protective measures of applying a coating or undergoing an anodizing process serve to augment their chemical resistance. In summary, 101 aluminum sheets are an ideal option for chemical processing environments, offering both corrosion resistance and durability when exposed to diverse chemicals.

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to know the dimensions (length, width, and thickness) of the sheet and the density of aluminum. The weight can be calculated by multiplying these three values together and then multiplying it by the density of aluminum.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Indeed, consumer goods can be manufactured using aluminum sheets. This material possesses qualities of being lightweight, durable, and easily moldable, allowing for the creation of diverse shapes and sizes. Its remarkable resistance to corrosion renders it perfect for items that may face moisture or harsh environments. Moreover, aluminum stands out as an environmentally conscious choice due to its high recyclability. The attractiveness, sturdiness, and adaptability of aluminum sheets render them an exceptional choice for producing consumer goods, including kitchen utensils, appliances, furniture, packaging materials, and automotive components.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

Send your message to us

POLISHED ALUMINIUM PLATES FOR MOLD PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords