Oem Aluminum Veneer Sheets - 5052 Aluminium Checker Plate for Boat Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5052 Aluminium Checker Plate for Boat Deck

l Description

1.Alloy number: 1100,3003,1050,1060,5052.

2.Temper: H14,H18,H12,H16,H22,H26,H24.

3.Brand: CMAX

4.Thickness: 0.8-10.0mm. width: 20-1600mm.

5.Tolerance: thick+/-0.02mm, width +/-0.5mm.

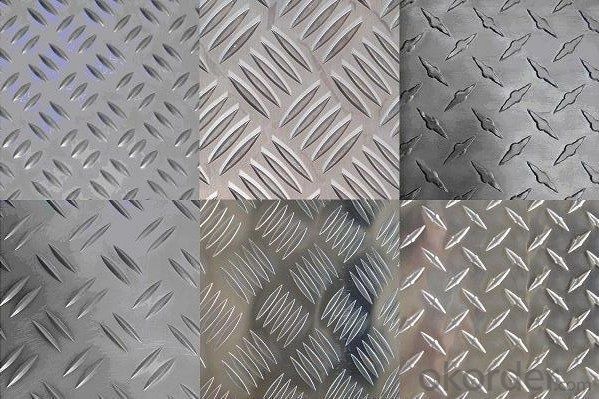

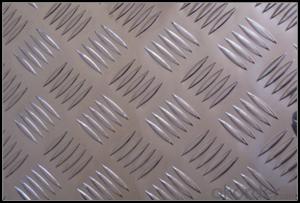

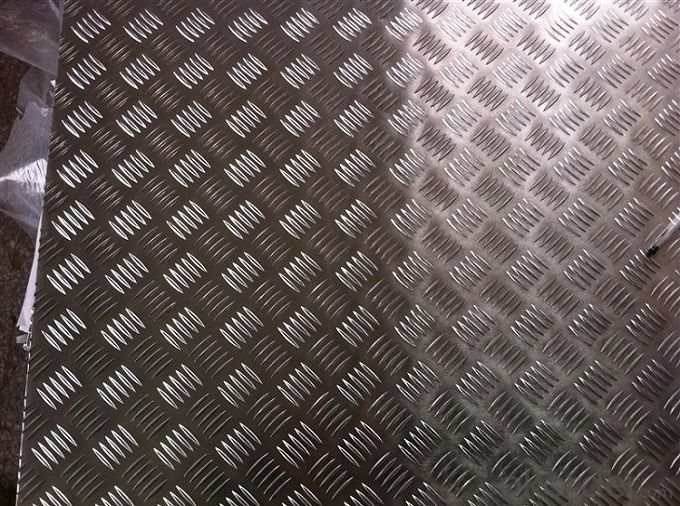

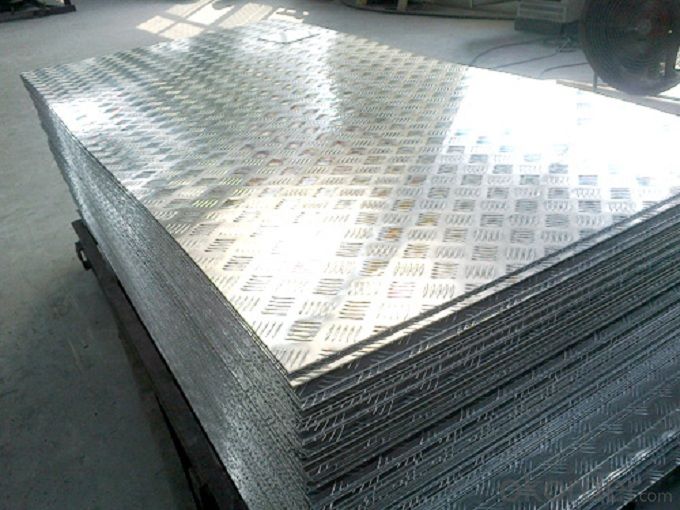

6.Pattern: Two bars, Three bars, Five bars and Diamond.

7.Surface brightness: bright surface or normall surface.

8.Application: trailer,truck,decking,flooring,stairs,steps,building industry.

9.Loading port: Shanghai or main port in China.

l Packaging & Delivery

Packaging detail: wooden pallets that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. Aluminium checker plate is a popular product in CNBM. With best quality and service, we have won reputation around the world.. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: General characteristics of pure aluminium plate of pure aluminium plate

- Comparison of pure aluminium sheets:1, grade: 1A85, 1A90, 1A93, 1A97, 1A99;Product type: plates, belts, foils, tubes;Main characteristics: Industrial high-purity aluminum;Applications: mainly used in the production of various electrolytic capacitor foil, acid fast container, etc., products have plates, belts, foils and so on.2, grade: 1060, 1050A, 1035;Product type: foil, wire;Main features: industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but the strength is low, it can not be strengthened by heat treatment, cutting is not good. Acceptable contact welding and gas welding;Scope of application: use the advantages of making some structures with specific properties, such as aluminum foil gasket and capacitor, electronic tube isolation network, wire and cable protective sleeve, net, wire core and aircraft parts and trim ventilation system.3, brand: 1100;Product type: Sheet & strip;Main features: for ordinary industrial pure aluminum aluminum content of 99%, can not be strengthened by heat treatment; low strength, but has good ductility, formability, weldability and corrosion resistance; anodic oxidation can improve corrosion resistance, and beautiful surface;Scope of application: mainly produces sheet metal and strip. Suitable for making all kinds of deep stamping products, and is widely used in various fields from cooking utensils to industrial equipment.

- Q: Can aluminum sheets be bent without cracking?

- Indeed, aluminum sheets possess the remarkable quality of being bendable without succumbing to cracks. This is due to aluminum's exceptional malleability and ductility, enabling it to be effortlessly molded and reshaped without experiencing fractures. Nevertheless, the success of bending aluminum sheets without cracks hinges upon various factors, including the sheet's thickness, the type and grade of aluminum employed, and the particular bending method employed. To guarantee its integrity and prevent cracks, it is crucial to utilize appropriate tools and techniques when embarking upon the task of bending aluminum.

- Q: I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- If it has a silvery-grey appearance and is very light, than it is probably aluminum, especially if you did a spark test and nothing happened(ruling out magnesium, which is unlikely for a random part anyway). Aluminum is alot lighter than steel, if you are holding it you would beable to tell. Magnesium is lighter than aluminum, but will give of red spark when touched with a grinder or shavings are lit. Cast aluminum can be welded with a wire spool gun, any certified aluminum shop(and most welding shops in general) would have one. It can also be Tig welded which would take longer but may yield a better result. *** Do not preheat the aluminum that hot, never preheat it more than 150°F, at 300°F you will start to degrade the aluminum, especially if it is an alloy. Aluminum melts at 1220°F but with preheat it would be possible to exceed that(especially with a spool gun). Do not do multipass beads without allowing it to cool. You will need to clean the oxide off the surface with a stainless steel brush or acid, normal steel will leave impurities that will affect you welding.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used as reflective surfaces due to their high reflectivity and low emissivity properties.

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Yes, aluminum sheets can be used for pharmaceutical lab equipment. Aluminum is a versatile material that offers various advantages for pharmaceutical applications. It is lightweight, corrosion-resistant, and has excellent thermal conductivity. These properties make aluminum an ideal choice for constructing lab equipment such as trays, shelves, and cabinets that are used for storage and transportation of pharmaceutical materials. Additionally, aluminum can be easily cleaned and sterilized, which is crucial for maintaining hygienic conditions in pharmaceutical laboratories. However, it is important to note that certain pharmaceutical processes may require specific materials that meet certain regulatory standards. Therefore, it is always advisable to consult with industry experts or regulatory bodies to ensure that the chosen aluminum sheets meet the necessary requirements for the intended use in pharmaceutical lab equipment.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: I did electrolysis by adding aluminum to the ends of the wire. I waited about 2 hours, and then I filtered the water. After it dried, I was left with powder. It's gray.It that aluminum powder or something else? I'm making thermite, if its not aluminum powder will it still work?

- Kinda sorta, the problem with this is that all you did was made aluminium oxide or hydroxide, when you electrolyzed the aluminium you also electrolyzed a bit of water with it, which added a hydroxyl group to the aluminum, which may have dropped a hydrogen when you dried it. If you could find an aluminium compound that is water soluble (DAMNED HARD to find) you could electrolyze it in water to get aluminium dust in the water, but that isnt very reliable or economical, the best thing for you to do is to get a ball mill or rock tumbler, add aluminium fold and about half full of regular marbles, let it run for 3 or so weeks. You need it really fine!

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and a good conductor of electricity. If you touch it, it will get grounded, so it will be neutral. You cannot charge a metal up by touching it with your hand unless you are not grounded yourself. If you are standing on a piece of plastic, say, then it will take whatever charge is on you. If you are positive, it will become positive. If you are negative, it will become negative. But you must be insulated from ground to do that. If you are touching the ground then any charge on the aluminum will just flow out of the metal through you to ground and the aluminum will stay neutral

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

- Q: Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

Send your message to us

Oem Aluminum Veneer Sheets - 5052 Aluminium Checker Plate for Boat Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords