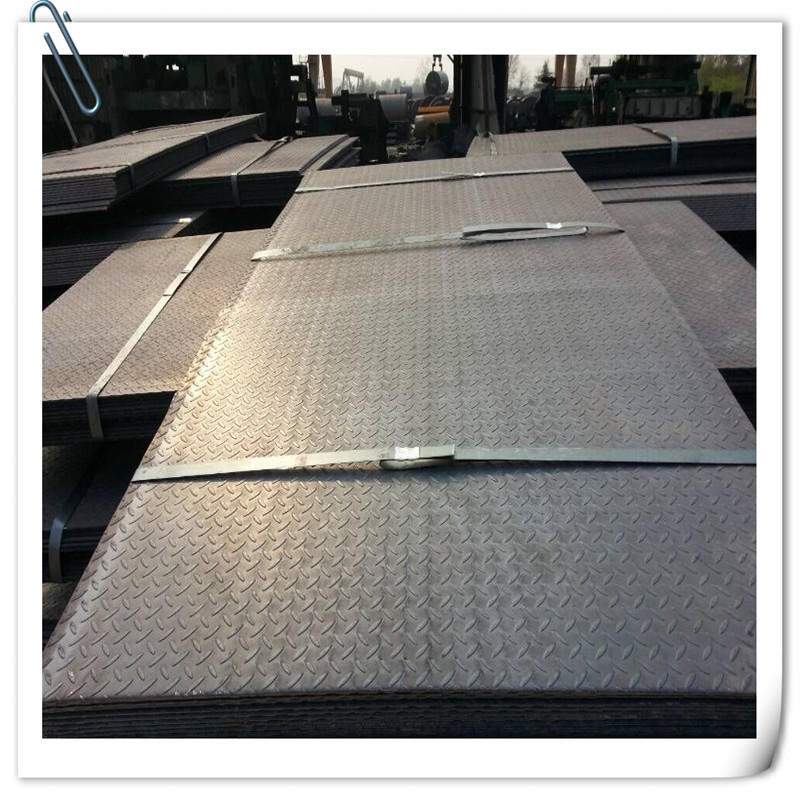

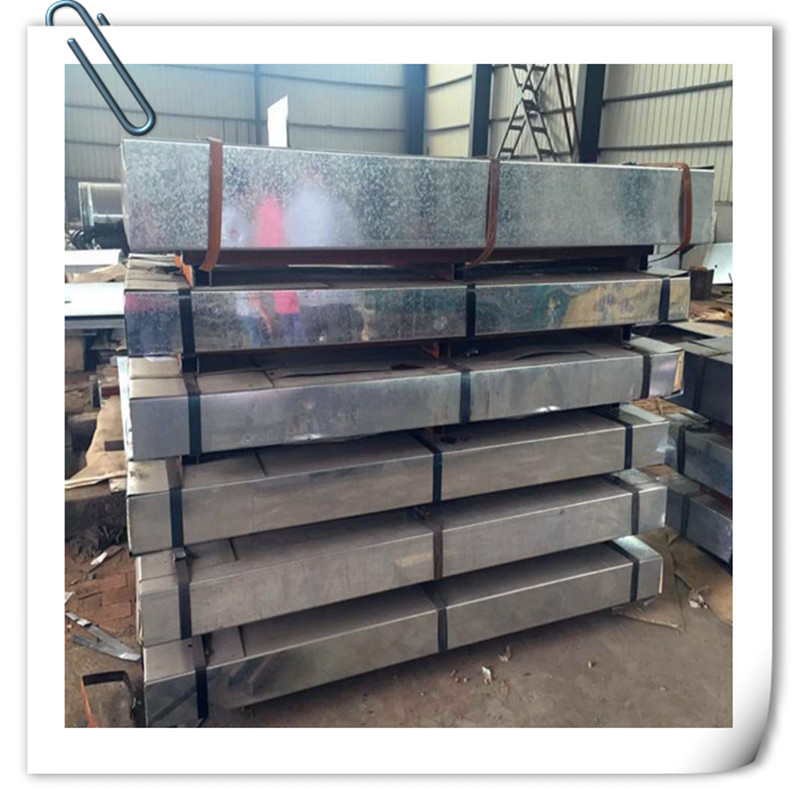

Hot Rolled Low Carbon Steel Checkered Plate/Sheet for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

We do care:

--Good Quality

--On-time Delivery

--Competitive Price

--Efficient After Service

Thickness | 2.0-18mm |

Width | 50-200mm |

Length | as custom's request |

Technique | hot rolled |

Surface treatment | Bare/Shot Blasted and Spray Paint or as required. |

Standard | ASTM,EN,GB,JIS,DIN |

Material | Q195, Q215A/B, Q235A/B/C/D, Q275A/B/C/D, SS330,SS400,S M400A, Cr. C, Cr.D,S235JR ,ASTM A36 |

Usage | Used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Package | Standard export sea-worthy packing |

Terms of Payment | L/C or T/T |

Delivery Detail | Within 15 days after receipt of deposited or L/C at sight |

Product information

Standard ackage for export:

- Q:i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- earlier you circulate approximately any extensive alterations, take the guitar to a qualified technician and notice approximately having the strings, or action diminished nearer to the fretboard. this could take very numerous soreness off of his palms, because it feels like the guitar hasn't been set-up in any respect, or a minimum of superb. A neck adjustment, if mandatory, might additionally help this issue. If he continues to be experiencing finger soreness (he might might desire to undergo some), attempt a lighter gauge set of strings (steel). a good tech can help you there, too. Nylon strings are not going to paintings properly in any respect on a non-classical guitar; the parameters are in basic terms different adequate between the two certainly one of them to end not something greater suitable than to waste your money. the main uncomplicated issue I see on a conventional foundation is that guitars are offered and offered without suitable set-up. An experienced tech will examine the neck configuration; the bridge alignment; saddle top; venture end; nut clearance; and action on an acoustic guitar. There are much greater info on an electric powered. Please detect a music/guitar save that does this form of paintings on the premises. My concept is that the finished relatives will income. Cheers decrease back atcha!

- Q:How are steel coils inspected for chemical composition?

- Steel coils are inspected for chemical composition through a process known as spectroscopy. Spectroscopy involves the use of a spectrometer, which is an instrument that analyzes the light emitted or absorbed by a sample to determine its chemical composition. In the case of steel coils, a small sample is usually taken from the coil and prepared for analysis. This sample is then placed in the spectrometer, which emits a beam of light onto the sample. The light interacts with the atoms and molecules in the sample, causing them to emit or absorb specific wavelengths of light. The spectrometer measures the intensity of the emitted or absorbed light at different wavelengths and creates a spectrum, which is essentially a unique fingerprint for the sample. This spectrum is then compared to a database of known spectra for different elements and compounds to determine the chemical composition of the steel. The spectroscopic analysis can identify the presence and concentration of various elements such as carbon, manganese, phosphorus, sulfur, and other trace elements that may be present in the steel. These elements play a crucial role in determining the steel's properties, strength, and suitability for different applications. Inspection for chemical composition is essential in the steel industry to ensure that the steel meets the required specifications and standards. Any deviation from the desired chemical composition can affect the steel's performance and may lead to structural failures or other defects. Overall, spectroscopy provides a highly accurate and reliable method for inspecting steel coils for their chemical composition, helping to ensure the quality and integrity of the steel products.

- Q:How are steel coils used in the manufacturing of tools?

- Steel coils are used in the manufacturing of tools as they provide a strong and durable material for the construction of various tool components. The coils are processed and shaped into specific forms, such as blades or handles, through cutting, shaping, and heat treatment processes. The resulting steel tool parts exhibit excellent strength, toughness, and resistance, making them suitable for a wide range of applications in industries like construction, automotive, and manufacturing.

- Q:What are the different types of steel coil slitting techniques?

- There are several types of steel coil slitting techniques, including rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using circular blades to cut the steel coil into narrower strips. Loop slitting involves creating a loop in the steel coil and then cutting it with straight blades. Oscillating slitting uses a reciprocating blade that moves back and forth to cut the coil into smaller widths.

- Q:What is the (balanced) chemical equation for steel?

- Steel is about 5% carbon and about 89 % iron, the rest is impurities of all sorts That is considered low carbon steel There are precise formulas for other steels like High Speed Steel, High Tensile low carbon, and thousands of other steels. Specialty steels are a big business item with thousand of tons sold each year for specialty applications.

- Q:I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- 'Plate' does not refer to a specific alloy. It simply describes the shape in which the metal is sold. Various steel alloys have varying degrees of weldability. Some weld well, with good strength. Others weld poorly, and crack or become very weak. Try looking up information on the specific alloy of steel.

- Q:Hi, I live in the Boston area and I'm trying to find a steel suppler that can provide mild steel for hobby welding. I can go through my job, but we only put in orders every couple of months so it's not very convenient. Also, the few suppliers I've found only sell in bulk. So if anyone knows where I can angle irons, flat bars, sheets, etc... by the piece it would greatly appreciated. Thanks

- They will sell any quantity of metal and even cut it to size - my experience has been that their prices are not wildly out of line for single pieces of full length stock compared to buying singles where you have to buy a minimum. They also may have sizes that ordinary places consider odd. I was looking for 5/8 square 16 gauge and was told it would have to be shipped in from Houston (to Dallas) by my nearest supplier and found it in stock at MetalSM. But check if you get something odd - the 5/8 cost more than 3/4 at both places and MetalSM actually gave me 3/4 but took it back even though I had cut it. Also check the regular steel suppliers in your area as well as retail welders metal supply places.

- Q:What are the different types of steel alloys used in coil manufacturing?

- There are several types of steel alloys used in coil manufacturing, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. Each alloy has different characteristics and properties that make it suitable for specific applications in coil manufacturing. Carbon steel is commonly used for general-purpose coils due to its affordability and versatility. Stainless steel is preferred for its corrosion resistance and aesthetic appeal, making it suitable for applications that require durability and a polished finish. HSLA steel, on the other hand, offers enhanced strength and toughness, making it ideal for demanding applications that require high performance and durability.

- Q:How are steel coils used in the production of steel hinges?

- Steel coils are used in the production of steel hinges by being uncoiled and then cut into specific lengths and widths. These coils serve as the raw material for the hinges, providing the necessary strength and durability.

- Q:Hello, Do I make any damage to my stainless steel sink by cleaning it with clorox? Thank you!

- I think not. I owned stainless steel sinks before that were they were in style. I used Clorox and more on them and they always turned out great. found wiping them out with a paper towel made them shine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Low Carbon Steel Checkered Plate/Sheet for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords