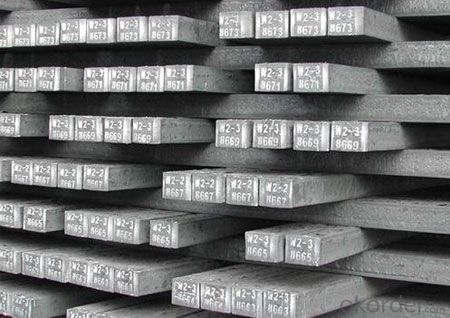

Steel Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continue casting round billets

Process: EAF+LF+VD+Continue CASTING,Delivery condtion:Hot forged+Normalzied+Rough Machined+Q/T.

Boiler Pipe Billets

Forging Steel Ingots

Stainless Steel Round Billets

Billets for Structural Seamless Pipe

Casing Steel Billets

Billets for Oil Well Casing Pipe

Stainless Steel Square Billets

Forging Square Steel Billets

Carbon Steel Square Billets

Stainless Steel Round Billets

Forging Round Billets

Line Pipe Steel Billets

Forging Ingot | |

| Range | Material |

| 5t-150t | Carbon Steel Ingot、Alloy Steel Ingot、Bearing Steel、Wind Power Steel、Nuclear Power Steel、Steel Mould Or Special Material |

Heavy Casting Or Forging Steel Billets | |

Casing Steel Billets: Min QTY 200 Ton、Forging Steel Billets: Min QTY 60Ton | Cooperative development according to customer requirements. |

The Continuous Casting Round Billet | ||

Name | Material | Size |

Billets for Structural Seamless Pipe | 10#、20#、35#、45#、345B、27SiMn、20Mn2 | φ180mm-φ600mm |

Billets for Low&Medium Pressure Boiler Pipe | 20# | φ180mm-φ600mm |

Billets for high pressure boiler pipe | 20G、SA-192、SA-106B、SA-106C、SA-210A1、SA-210B、SA-210C、37Mn、34Mn2V、30CrMo、35CrMo、34CrMo4、SA335-P2、SA335-P11、SA335-P12、16MnG、25MnG、15MoG、16Mo3、13CrMo4-4、10CrMo9-10、15CrMoG、12Cr1MoVG | Φ180mm-Φ600mm |

Billets for Oil Well Casing Pipe | 37Mn5、34Mn6、25Mn2V、30Mn2V-36Mn2V、26CrMo4、32CrMo4、29MnCr6、29CrMo4-4、40CrMo4 | Φ180mm-Φ600mm |

Billets for Line Pipe | L245(B)、L245NB、X42(L290)、X46(L320)、X52(L360)、L320NB、L360NB、L245NCS、L290NCS、L360NCS | Φ180mm-Φ600mm |

Forging Round Steel Billets & Square Billets | 45#、50Mn、40Cr、GCr15、GCr15SiMn、Q345E、35CrMo、42CrMo、42CrMo4 | Round Steel Billets:φ180mm-φ600mm |

Stainless Steel Round Billets &Square Billets | 1Cr13、2Cr13、3Cr13、4Cr13、1Cr18Ni9Ti | Round Steel Billets:φ180mm-φ600mm |

- Q: What are the potential applications of steel billets in the medical aftermarket?

- Steel billets have a wide range of potential applications in the medical aftermarket. One key application is in the manufacturing of surgical instruments. Steel billets can be used to produce high-quality, durable surgical instruments such as scalpels, forceps, scissors, and orthopedic implants. The strength and corrosion resistance of steel make it an ideal material for these critical medical tools. Additionally, steel billets can be used in the production of medical equipment and devices. For example, they can be used to manufacture components for X-ray machines, CT scanners, and MRI machines. Steel's excellent conductivity and high strength-to-weight ratio make it a suitable choice for these demanding applications. Furthermore, steel billets can be utilized in the production of medical furniture and fixtures. Steel is commonly used in the construction of hospital beds, examination tables, and cabinets due to its durability and ease of maintenance. Steel billets can provide the necessary raw material for the manufacturing of these essential medical items. Moreover, steel billets can also be employed in the fabrication of prosthetics and orthotics. These devices often require strong and lightweight materials to ensure proper functionality and comfort for patients. Steel billets can be processed into various shapes and sizes to create prosthetic limbs, braces, and other orthopedic devices. In conclusion, the potential applications of steel billets in the medical aftermarket are diverse and crucial. From surgical instruments to medical equipment, furniture, and prosthetics, steel billets offer the necessary strength, durability, and corrosion resistance to meet the demanding requirements of the medical industry.

- Q: Can steel billets be used in the production of kitchenware?

- Kitchenware can indeed be made using steel billets. Steel billets, which are essentially unfinished steel products that have been cast into a rectangular shape, can undergo further processing through methods such as forging, rolling, or extrusion. These processes allow for the creation of a wide range of kitchenware items, including pots, pans, utensils, and cutlery. The use of steel in kitchenware production is popular due to its exceptional strength, durability, and resistance to heat. It is also well-known for its ability to resist corrosion, making it safe for contact with food and liquids. Furthermore, steel is easy to clean and maintain, making it a hygienic choice for kitchenware. The typical manufacturing process involves heating and shaping the steel billets into the desired form, followed by finishing processes like polishing or coating to improve both the aesthetics and functionality of the kitchenware. With the versatility to produce kitchenware in various shapes, sizes, and designs, steel billets provide a flexible solution for creating high-quality and long-lasting kitchenware items.

- Q: How are steel billets used in the manufacturing of tools?

- Steel billets are used in the manufacturing of tools as the starting material. They are heated, shaped, and machined into various tool components, such as cutting blades, drill bits, or molds, to achieve the desired shape and strength.

- Q: What are the different methods of steel billet surface treatment?

- There are several methods of steel billet surface treatment that are commonly used in the industry. These methods aim to enhance the surface properties of the steel billets, such as improving corrosion resistance, increasing hardness, and improving aesthetics. Some of the most common methods of steel billet surface treatment are: 1. Pickling and Passivation: This process involves the removal of impurities and oxide layers from the steel surface using acid solutions. After pickling, the steel is passivated to create a protective layer that prevents future corrosion. 2. Shot Blasting: Shot blasting is a mechanical surface treatment method that involves the use of high-speed steel shots or grits to bombard the surface of the billets. This process removes scale, rust, and other contaminants, resulting in a clean and uniform surface. 3. Hot-Dip Galvanizing: In this process, the steel billets are immersed in a bath of molten zinc, which forms a protective coating on the surface. This method provides excellent corrosion protection, making it suitable for outdoor applications. 4. Electroplating: Electroplating involves the deposition of a thin layer of metal, such as chrome or nickel, onto the steel surface using an electric current. This method improves the appearance of the steel, enhances corrosion resistance, and can also provide better wear resistance. 5. Powder Coating: Powder coating is a popular method of surface treatment, especially for aesthetic purposes. It involves applying a dry powder onto the steel surface and then curing it through heat, resulting in a durable and attractive finish. 6. Painting: Painting is another common method used for surface treatment. The steel surface is first cleaned and primed before applying a suitable paint system. This method not only enhances the appearance but also provides protection against corrosion and environmental factors. 7. Nitriding: Nitriding is a heat treatment process that involves the diffusion of nitrogen into the steel surface. This method improves the hardness, wear resistance, and fatigue strength of the billets. These are just a few of the various methods of steel billet surface treatment available. The choice of method depends on the specific requirements of the application, desired properties, and budget considerations.

- Q: How do steel billets contribute to the manufacturing of household appliances?

- Steel billets play a crucial role in the manufacturing of household appliances. These billets serve as the raw material for the production of various components and structures used in household appliances. Firstly, steel billets are used to manufacture the frames and structures of appliances such as refrigerators, washing machines, and dishwashers. The high strength and durability of steel make it an ideal choice for these applications, ensuring that the appliances can withstand the constant use and heavy loads they encounter. Secondly, steel billets are used to produce the inner and outer panels of household appliances. These panels require a material that is strong, resistant to corrosion, and aesthetically pleasing. Steel fits these criteria perfectly, providing a sleek and durable surface that can be easily cleaned and maintained. Additionally, steel billets are used to create various components within household appliances, including heating elements, motors, and electrical parts. Steel's excellent thermal conductivity and electrical properties make it a suitable material for these critical components, ensuring efficient operation and reliable performance. Furthermore, steel billets contribute to the overall safety of household appliances. Steel is a fire-resistant material, reducing the risk of accidents caused by overheating or electrical malfunctions. Its strength and stability also play a role in preventing structural failures that could lead to accidents or injuries. In summary, steel billets are essential in the manufacturing of household appliances due to their strength, durability, corrosion resistance, and thermal/electrical properties. By providing the necessary raw material, steel billets enable the production of robust structures, aesthetic panels, critical components, and safe appliances that meet the demands and expectations of consumers.

- Q: What are the different types of steel used in manufacturing steel billets?

- Steel billets are manufactured using various types of steel, including carbon steel, stainless steel, alloy steel, and tool steel. 1. Carbon Steel: The most commonly used steel for manufacturing steel billets is carbon steel. It contains a small percentage of carbon (typically 0.05% to 0.25%), which provides it with strength and durability. Carbon steel is versatile and can be used in a wide range of applications. 2. Stainless Steel: Stainless steel is highly regarded for its corrosion resistance and high strength. It contains chromium, which forms a protective oxide layer on the surface, preventing rust and corrosion. Stainless steel is commonly used in applications where resistance to moisture and chemicals is necessary, such as in the construction of bridges and buildings. 3. Alloy Steel: Alloy steel is created by adding different alloying elements to carbon steel, including manganese, nickel, chromium, and molybdenum. These elements enhance the steel's properties, such as its strength, hardness, and resistance to wear and tear. The automotive and aerospace industries frequently employ alloy steel. 4. Tool Steel: Tool steel is specifically designed to possess high hardness, resistance to abrasion, and the ability to withstand high temperatures. It is frequently utilized in the production of cutting tools, molds, and dies. Tool steel typically comprises a combination of alloying elements, such as tungsten, vanadium, and cobalt. These examples represent a few of the diverse types of steel employed in the manufacturing of steel billets. The selection of the specific steel type relies on the desired properties and intended application of the steel billets.

- Q: What are the different types of defects that can occur during steel billet production?

- During the production of steel billets, various defects may arise, which can compromise the quality and performance of the final product. Some commonly observed defects in steel billets include the following: 1. Surface Defects: These defects manifest on the billet's surface and may include scales, cracks, pits, scars, and slivers. Improper handling, inadequate lubrication, insufficient heating, or contamination during the manufacturing process can cause surface defects. 2. Internal Defects: Internal defects occur within the billet and can be more challenging to detect. Examples of internal defects include voids, porosity, inclusions, and segregation. Improper alloying, inadequate mixing, or flawed casting and solidification processes can lead to internal defects. 3. Shape Defects: Shape defects refer to deviations from the desired dimensions or geometry of the billet. These defects may include bending, bowing, twisting, or excessive tapering. Improper rolling or cooling processes, inadequate maintenance of rolling equipment, or mishandling of billets can cause shape defects. 4. Chemical Composition Defects: Steel billets must meet specific chemical composition requirements to ensure desired material properties. Defects in chemical composition may occur due to improper mixing of raw materials, incorrect temperature control, or contamination during the manufacturing process. Such defects can negatively impact the mechanical properties of the final product, such as strength, ductility, or corrosion resistance. 5. Incomplete Solidification: Defects like centerline segregation or shrinkage cavities can arise from incomplete solidification. This occurs when the cooling rate is too fast or uneven, preventing the complete solidification of the billet. Incomplete solidification weakens the billet structure, affecting its overall integrity and performance. 6. Dimensional Defects: Dimensional defects involve variations in the size, length, width, or thickness of the billet. These defects may result from inaccurate measurement or control during the manufacturing process. Dimensional defects can hinder the fitment or compatibility of the billet in subsequent processes or applications. To minimize the occurrence of these defects, steel billet manufacturers must implement rigorous quality control measures. Regular inspections, process optimization, and adherence to industry standards and best practices can help mitigate defects and ensure the production of high-quality steel billets.

- Q: What industries rely heavily on steel billets?

- The industries that heavily rely on steel billets include construction, automotive, aerospace, and manufacturing.

- Q: What is the role of steel billets in the construction of residential buildings?

- Steel billets are an essential component in the construction of residential buildings as they serve as the raw material for manufacturing various structural steel elements. These billets are heated, shaped, and transformed into different forms such as beams, columns, and reinforcing bars, which provide strength and stability to the building's framework. Additionally, steel billets are also used in the fabrication of other critical components like wall panels and roof trusses, ensuring durability and safety in residential construction.

- Q: What are the different shapes of steel billets?

- Steel billets can come in various shapes, including square, round, rectangular, and hexagonal.

Send your message to us

Steel Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords