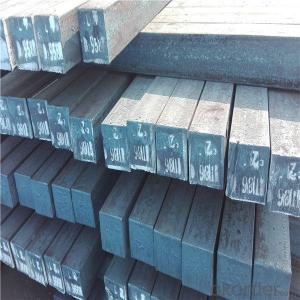

hot rolled steel billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Packaging & Delivery

| Packaging Detail: | in bundles |

| Delivery Detail: | according to the quantity |

Specifications

square steel billet

1.3SP, 5SP

2.terms of payment: L/C at sight

3.size: 120*120mm

4.length: 5.8~12m

square steel billet

Specifications

square steel billets

1)We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

M.S. Billets

CRS Billets

Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

120x120

150 X 150

Physical Properties:

Description | As per IS 2830 | Shyam Billets |

| Bend (max.) | 5 mm per meter | >= 5 mm per meter |

| Carbon (max.) | 3mm per meter | >= 3 mm per meter |

| Length | 3 mt - 13 mt | 3 mt - 9 mt |

Chemical Properties:

Ladle Analysis: | ||

Designation | Carbon | Manganese |

| C15 | 0.12-0.18 | 0.30-0.60 |

| C18 | 0.15-0.21 | 0.30-0.60 |

| C20 | 0.17-0.23 | 0.30-0.60 |

| C15 MMn | 0.12-0.18 | 0.60-1.00 |

| C18 MMn | 0.15-0.21 | 0.60-1.00 |

| C20 MMn | 0.17-0.23 | 0.60-1.00 |

| C15 HMn | 0.12-0.18 | 1.00-1.50 |

| C18 HMn | 0.15-0.21 | 1.00-1.50 |

C20 HMn | 0.17-0.23 | 1.00-1.50 |

Billets of different designations are manufactured in three different grades namely A, B, C having sulphur, phosphorous content (on ladle analysis) and carbon equivalent as follows:

| Chemical Analysis: | |||

| Grade | Sulphur | Phosphorous | Carbon Equivalent (CE)1 |

| Max | Max | Max | |

| A | 0.05 | 0.05 | 0.42 |

| B | 0.045 | 0.045 | 0.41 |

| C | 0.04 | 0.04 | 0.39 |

- Q: How are steel billets used in the production of electrical transmission towers?

- Steel billets are used in the production of electrical transmission towers as they serve as the raw material for the manufacturing process. These billets are melted and then shaped into the required sections and components of the transmission tower, such as the main legs, cross arms, and braces. They undergo further processing, including cutting, drilling, and welding, to form the final structure. The strength and durability of steel make it an ideal material for transmission towers, ensuring they can withstand the weight of electrical cables and withstand harsh environmental conditions.

- Q: How are steel billets shaped into other forms?

- Steel billets are shaped into other forms through a process called hot or cold working. In hot working, the billets are heated to high temperatures and then shaped using various methods like rolling, forging, or extrusion. Cold working involves shaping the billets at room temperature through processes such as drawing, bending, or pressing. These techniques allow the steel billets to be transformed into different shapes and sizes according to the desired end product.

- Q: Can steel billets be used in the production of energy-efficient appliances?

- Yes, steel billets can be used in the production of energy-efficient appliances. Steel is a versatile and durable material that can be formed into various components of appliances, such as shells, frames, and internal structures. When properly designed and manufactured, steel components can contribute to the overall energy efficiency of appliances by ensuring better insulation, heat distribution, and overall performance.

- Q: Are steel billets used in the manufacturing of tools?

- Yes, steel billets are commonly used in the manufacturing of tools. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes, including bars, rods, and sheets. These billets serve as the primary raw material in tool manufacturing, as they provide the necessary strength, durability, and machinability required for producing high-quality tools. By shaping and machining the steel billets, manufacturers can create a wide range of tools such as wrenches, hammers, screwdrivers, drill bits, and cutting tools. The use of steel billets ensures that these tools possess the necessary hardness, toughness, and resistance to wear and tear, making them reliable and long-lasting. Therefore, steel billets play a crucial role in the production of tools, contributing to the overall efficiency and functionality of various industries.

- Q: Are steel billets prone to corrosion?

- Yes, steel billets are prone to corrosion. Steel is primarily made from iron, and iron is susceptible to rusting and oxidation when exposed to moisture and oxygen. Therefore, steel billets, which are the raw form of steel used for further processing, can corrode if not properly protected or maintained.

- Q: I want to buy a fishing pole, I don't know how to distinguish it. Know what, please reply, thank you, [em10]!

- When it comes to the differentiation of carbon fishing rods, first of all, what are the different kinds of fishing rods containing carbon?!Carbon rod is now sold in the market are divided into three kinds, namely: carbon, pure carbon, high carbon. These three categories.1, carbon packaging, as its name implies, two layers of material, the outside layer is carbon cloth, the inside layer is glass fiber, epoxy cloth. The price of this kind of rod is lower, because it is not necessary to buy a brand because of the lower price. With a few times you can change, for beginners.2, pure carbon refers to the overall use of 30T below carbon cloth fishing rod, general 24T, 30T based, carbon content of more than 98%. Moderate price.3, high carbon refers to the overall use of more than 30T carbon cloth fishing rod, but not the whole fishing rod is made of a carbon cloth. The tonality of a fishing rod is actually modulated by a different modulus of carbon cloth.Some fishing overall with the 30T following carbon cloth, just use a very small amount of 40T or 46T carbon cloth, called high carbon rod, is actually confuse the public practice of fishing by weighing, hand identification, high carbon rod with real light, hard, two rods in a play, a ratio is obvious.

- Q: How do steel billets contribute to the construction industry?

- The construction industry relies heavily on steel billets for several key reasons. Firstly, they serve as the primary material for producing a range of steel products used in construction, including beams, columns, and reinforcement bars. These products are essential for providing structural support and integrity to buildings and infrastructure projects. Steel billets are also vital in the manufacturing of precast concrete elements, which are widely utilized in construction. By reinforcing pre-stressed concrete beams with steel billets, their strength and durability are significantly enhanced. This enables the construction of larger and more intricate structures like bridges, stadiums, and high-rise buildings. Additionally, steel billets play a crucial role in the fabrication of steel pipes and tubes, which are extensively employed in water supply systems, sewage lines, and gas pipelines. These pipes ensure the reliable and efficient transportation of fluids and gases, thereby facilitating the proper functioning of various infrastructure networks. Apart from their structural applications, steel billets also contribute to the construction industry through their recyclability. Steel is one of the most globally recycled materials, and steel billets can be melted and reused multiple times without any loss in quality. This not only reduces the demand for new steel production but also minimizes environmental impact and waste generation. In summary, steel billets are indispensable in the construction industry due to their versatility, strength, and recyclability. They serve as the foundation for producing various steel products and play a critical role in constructing durable and sustainable buildings and infrastructure projects.

- Q: How are steel billets used in the production of agricultural irrigation systems?

- Steel billets are an essential component in the production of agricultural irrigation systems. These billets, which are semi-finished steel products, are used to create various components of irrigation systems such as pipes, fittings, and valves. When manufacturing irrigation pipes, steel billets serve as the raw material that undergoes a series of processes to form seamless or welded pipes. The billets are heated and then passed through a piercing mill, where they are further elongated and shaped into a hollow tube. These tubes are then stretched and rolled to achieve the desired diameter and thickness. The resulting steel pipes are strong, durable, and resistant to corrosion, making them ideal for use in agricultural irrigation systems. Steel billets are also used to produce fittings and valves for irrigation systems. Fittings such as elbows, tees, and reducers are manufactured by shaping and machining steel billets to meet specific size and shape requirements. These fittings are crucial in connecting and directing water flow within the irrigation system. Additionally, steel billets are sometimes used in the production of pump housings and other structural components of irrigation systems. Due to their strength and stability, steel billets provide the necessary support and durability required in these applications. Overall, steel billets play a vital role in the production of agricultural irrigation systems by providing a reliable and robust material for pipes, fittings, valves, and other components. Their use ensures the longevity and efficiency of these systems, allowing for effective water distribution and irrigation in agricultural fields.

- Q: How are steel billets used in the production of industrial furnaces?

- Steel billets are used in the production of industrial furnaces as the primary raw material for constructing the furnace structure and components. These billets are melted and molded into various shapes and sizes to create the furnace body, walls, doors, and other necessary parts. The high strength and heat resistance of steel make it ideal for withstanding the extreme temperatures and harsh conditions within the furnace, ensuring its durability and longevity.

- Q: How are steel billets used in the production of construction machinery attachments?

- The production of construction machinery attachments relies heavily on steel billets, which act as essential raw materials. These billets undergo a series of processes to shape and transform them into different components required for the attachments. To start, the steel billets are subjected to high temperatures to increase their malleability and facilitate easier manipulation. Subsequently, they are passed through specialized machines like rolling mills and forging presses, effectively molding them into the desired forms. This transformation allows the billets to take on various shapes such as bars, plates, and rods, which are vital for construction machinery attachments. Once shaped, the billets undergo further procedures like cutting, drilling, and shaping to create specific parts of the attachments. For instance, they can be cut and shaped to form the teeth of excavator buckets or the blades of bulldozer attachments. These parts must possess durability and strength to withstand the demanding conditions found on construction sites, and steel billets provide the necessary qualities. Furthermore, the utilization of steel billets guarantees that construction machinery attachments can endure heavy loads, impacts, and extreme temperatures. Steel is renowned for its high strength-to-weight ratio, making it an ideal material for these attachments. It can withstand the harsh conditions of construction sites and contribute to the longevity and performance of the attachments. In conclusion, steel billets play a critical role in the production of construction machinery attachments. They are transformed into various components, ensuring durability, strength, and longevity. By utilizing steel billets, construction machinery attachments can effectively fulfill their intended functions and withstand the demanding conditions encountered on construction sites.

Send your message to us

hot rolled steel billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords