hot rolled billet steel producers in very good price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Brief description

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Features

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

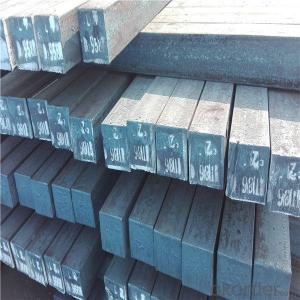

4.Pictures

5.Usage

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6.Detailed specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin : China

Inspection:Third party inspection before loading.

- Q: Are steel billets used in the manufacturing of oil and gas pipelines?

- Yes, steel billets are commonly used in the manufacturing of oil and gas pipelines. Steel billets are semi-finished products that are typically produced through a process called continuous casting, where molten steel is solidified into a rectangular shape. These billets serve as the starting material for various steel products, including pipes used in the oil and gas industry. The manufacturing process of oil and gas pipelines involves several steps, one of which is the production of seamless or welded steel pipes. Steel billets are heated and then rolled into tubes or pipes through a process called pipe making. For seamless pipes, the heated billet is pierced to form a hollow shell, which is then elongated and shaped into a pipe. Welded pipes are created by rolling and welding a flat plate of steel to form a tube. The use of steel billets in pipeline manufacturing is preferred due to the excellent mechanical properties of steel, including its strength, durability, and resistance to corrosion. These properties make steel an ideal material for pipelines that need to withstand high-pressure environments and harsh conditions. Additionally, steel billets can be customized in terms of size, shape, and composition to meet the specific requirements of each pipeline project. In conclusion, steel billets play a crucial role in the manufacturing of oil and gas pipelines. They serve as the raw material that is transformed into seamless or welded pipes, which are then used to transport oil and gas across long distances. The use of steel ensures the reliability and integrity of these pipelines, making them essential components of the oil and gas industry.

- Q: What is the role of steel billets in the construction of commercial buildings?

- Steel billets play a crucial role in the construction of commercial buildings as they serve as the raw material for various structural elements. These billets are heated and then shaped into different forms, such as beams, columns, and bars, which provide the necessary strength and stability to support the weight of the building. Additionally, steel billets are often used to create reinforcements within concrete structures, enhancing their durability and resistance to external forces. Overall, steel billets are essential for creating the skeletal framework of commercial buildings, ensuring their structural integrity and safety.

- Q: Is there an export duty? Or is there a tax refund?

- It's too broad. What kind of material (contains all kinds of metal components in order to confirm HS coding)?

- Q: What is the role of steel billets in the manufacturing of structural steel bridges?

- Steel billets play a crucial role in the manufacturing of structural steel bridges as they serve as the primary raw material for the production of steel beams and other structural components. These billets are heated and then shaped into desired forms through processes like rolling or forging. Their high strength and durability make them ideal for constructing the load-bearing elements of bridges, ensuring the structural integrity and longevity of the final bridge product.

- Q: Are billet metals within the metal range?

- Ah, metal materials, ferrous metals, color metals, two kinds of billets belong to ferrous metals, copper and copper alloys, aluminum and aluminum alloys, belonging to color metal

- Q: What are the different grades of steel used for making billets?

- There are several different grades of steel used for making billets, including low carbon steel, mild steel, medium carbon steel, high carbon steel, and alloy steel. The specific grade chosen depends on the desired properties and characteristics required for the intended application of the billets.

- Q: How are steel billets used in the production of aerospace components?

- Steel billets are used in the production of aerospace components as they serve as the starting material for the manufacturing process. Steel billets are essentially semi-finished steel forms that are hot-rolled or forged into specific shapes and sizes. In the aerospace industry, steel billets are typically used to produce critical components such as landing gear, engine components, structural parts, and fasteners. These billets are chosen for their superior strength, durability, and resistance to high temperatures and corrosive environments, which are crucial properties required for aerospace applications. The production of aerospace components using steel billets involves several steps. First, the billets are heated to a high temperature to make them malleable and easy to work with. They are then subjected to various forming processes such as forging, extrusion, or rolling, which shape them into the desired form. These processes allow for precise shaping and dimensional accuracy, ensuring that the components meet the required specifications and tolerances. After the initial shaping, the aerospace components are subjected to further processes such as heat treatment, machining, and surface finishing to enhance their mechanical properties and improve their surface quality. Heat treatment processes such as quenching and tempering are used to strengthen the steel and improve its hardness, toughness, and resistance to wear and fatigue. Machining processes are then employed to achieve the final shape, size, and surface finish of the components. Once the components are manufactured, they undergo rigorous quality control procedures to ensure they meet the stringent standards and regulations of the aerospace industry. This includes thorough inspections, non-destructive testing, and material analysis to verify their integrity, performance, and safety. In summary, steel billets are essential in the production of aerospace components as they provide a reliable and strong starting material. The versatility and excellent mechanical properties of steel make it a preferred choice in the aerospace industry, where reliability and safety are of utmost importance.

- Q: What are the challenges faced in the distribution and supply chain of steel billets?

- Some challenges faced in the distribution and supply chain of steel billets include transportation and logistics issues, such as the need for specialized equipment and efficient handling processes due to the heavyweight and bulky nature of steel billets. Additionally, ensuring timely delivery and managing inventory levels can be challenging due to various factors like unpredictable demand fluctuations and production delays. Quality control and inspection of steel billets during transit and storage is also crucial to prevent damage or deterioration. Lastly, coordinating with multiple stakeholders, including suppliers, manufacturers, distributors, and customers, requires effective communication and collaboration to maintain a smooth and reliable supply chain.

- Q: What are the different methods of steel billet surface shot blasting?

- There are several different methods of steel billet surface shot blasting, including air blast, wheel blast, and centrifugal blast. Each method involves propelling abrasive particles at high speeds onto the surface of the billet to remove any scale, rust, or contaminants. The choice of method depends on factors such as the desired surface finish, production volume, and equipment availability.

- Q: How are steel billets straightened after rolling or forging?

- After the rolling or forging process, steel billets may have irregularities or bends. To straighten them, various methods can be employed depending on the size and shape of the billets. One common method is known as rotary straightening. In this process, the billets are passed through a series of rotating rolls or wheels that exert pressure on the material, gradually straightening it out. The rolls are usually positioned at different angles to ensure an even distribution of force across the billet. This method is often used for smaller billets or those with slight bends. For larger and thicker billets, hydraulic straightening is often employed. Hydraulic presses or jacks are used to apply controlled pressure at specific points along the length of the billet. By adjusting the pressure at different points, the billet is gradually straightened. This method is more suitable for heavier and more severely bent billets. In some cases, heat can also be used to aid in the straightening process. Heat straightening involves heating the bent section of the billet to a specific temperature and then applying pressure to straighten it while it is still hot. This method is particularly effective for billets with significant bends or twists. It is important to note that the straightening process requires careful control and monitoring to prevent over-straightening or excessive stress on the material. Skilled operators and advanced equipment are necessary to ensure the billets are straightened effectively and within the desired tolerances.

Send your message to us

hot rolled billet steel producers in very good price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords