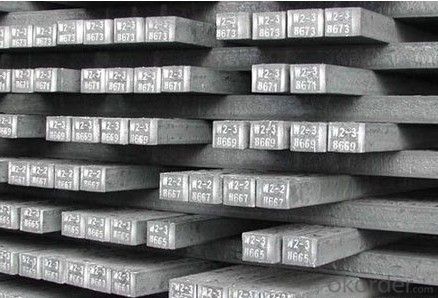

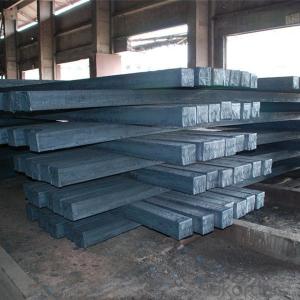

Square Shape Hot Rolled Mild Steel Billet 60mm-150mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Shape Hot Rolled Mild Steel Billet 60mm-150mm at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Square Shape Hot Rolled Mild Steel Billet 60mm-150mmare ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Square Shape Hot Rolled Mild Steel Billet 60mm-150mm are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195/Q235/Q275/20MnSi

Certificates: ISO, SGS, BV

size:60*60/90*90/100*100/120*120/150*150

Length: 6m/12m,

Packaging: Export packing, nude packing, bundled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: What is the difference between steel billets and steel ingots?

- Steel billets and steel ingots are both intermediate forms of steel used in the manufacturing process, but they differ in terms of their shape and size. Steel billets are smaller, square or round-shaped solid bars, typically measuring around 2 to 7 inches in diameter, and are produced through continuous casting or hot rolling processes. On the other hand, steel ingots are larger, rectangular or cylindrical-shaped blocks, with dimensions ranging from a few inches to several feet, and are usually produced through the traditional casting method. The main distinction lies in their size and shape, with billets being smaller and more manageable for further processing, while ingots are larger and require additional steps, such as forging or rolling, to be transformed into usable steel products.

- Q: How are steel billets used in the production of industrial boilers?

- Steel billets are an essential component in the production of industrial boilers. These billets, which are typically made of high-quality steel, serve as the raw material for fabricating the various parts and components of a boiler. The manufacturing process starts with the steel billets being heated to a specific temperature, which allows them to be easily shaped and formed. They are then passed through a series of rolling mills, where they are transformed into different shapes and sizes, such as plates, bars, or tubes, depending on the specific requirements of the boiler design. These billets are then further processed to create the necessary boiler components. For example, plates are cut and shaped to form the boiler shell, which serves as the main structure of the boiler. Bars are used to create the boiler tubes, which are responsible for transferring heat from the combustion chamber to the water. Additionally, other parts such as flanges, fittings, and supports are also made from steel billets. The quality and strength of the steel billets used in the production of industrial boilers are crucial factors in ensuring the durability and efficiency of the final product. Steel billets with high tensile strength and excellent heat resistance properties are preferred, as they can withstand the high pressures and temperatures associated with boiler operations. In summary, steel billets play a critical role in the production of industrial boilers by providing the raw material necessary for fabricating the various components. Their versatility, strength, and durability make them an ideal choice for creating the robust and reliable boilers required for a wide range of industrial applications.

- Q: How do steel billets contribute to the environmental sector?

- There are several ways in which steel billets contribute to the environmental sector. Firstly, the production of steel billets often involves the recycling of scrap metal, which helps decrease the demand for raw materials and conserve natural resources. This process also reduces the energy needed for steel production, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Moreover, steel billets find extensive use in construction projects, including the development of infrastructure and renewable energy installations. Steel is an incredibly durable material that can withstand harsh weather conditions and has a long lifespan. By utilizing steel billets in construction, we can create structures that require minimal maintenance and repair, reducing the necessity for frequent replacements and conserving additional resources. Furthermore, steel billets play a crucial role in the manufacturing of environmentally friendly products. Steel is a crucial component in the production of electric vehicles, wind turbines, and solar panels. These clean energy solutions aid in reducing our dependence on fossil fuels and decreasing harmful emissions, thus contributing to a cleaner and greener environment. Additionally, steel billets can be recycled once again at the end of their lifespan, further diminishing waste and minimizing the environmental impact. Recycling steel is an extremely efficient process that necessitates less energy and generates fewer emissions compared to the production of new steel from raw materials. In conclusion, steel billets contribute to the environmental sector through their recycling capabilities, durability in construction, and their role in the manufacturing of eco-friendly products. By incorporating steel billets into various industries, we can promote sustainability, conserve resources, and diminish our environmental footprint.

- Q: What are the different types of welding processes used for joining steel billets?

- When it comes to joining steel billets, there are various welding processes available, each with its own unique characteristics and advantages depending on the project's specific requirements. Here, we present some of the commonly used welding processes for joining steel billets: 1. Shielded Metal Arc Welding (SMAW), also known as stick welding, utilizes a consumable electrode coated in flux that creates an arc between the electrode and the base material. This versatile process can be used for both thick and thin steel billets, making it widely employed in various industries. 2. Gas Metal Arc Welding (GMAW), commonly referred to as MIG welding, involves a continuous wire electrode and a shielding gas that protects the weld from atmospheric contamination. This process offers high productivity and is suitable for welding steel billets of different thicknesses. 3. Flux-Cored Arc Welding (FCAW), similar to GMAW, employs a continuously fed tubular electrode filled with flux. It is particularly suitable for welding thicker steel billets and finds applications in heavy fabrication. 4. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, utilizes a non-consumable tungsten electrode and a separate filler metal. This process produces high-quality welds and is commonly used in applications that require precision and aesthetic appeal. 5. Submerged Arc Welding (SAW) involves a continuously fed electrode and a granular flux that covers the weld area. It is particularly suitable for welding thick steel billets and is often used in the construction of pressure vessels and heavy machinery. 6. Laser Beam Welding (LBW) employs a laser beam to generate heat and join the steel billets. This process offers high precision and speed, making it suitable for a wide range of applications, including automotive and aerospace industries. 7. Electron Beam Welding (EBW) uses a high-velocity electron beam to melt and join the steel billets. This process provides deep penetration and precise control, making it ideal for critical applications that require high-quality welds. When selecting the appropriate welding process, it is crucial to consider the specific requirements, thickness, and material properties of the steel billets. Consulting with a welding expert can help determine the most suitable method for a given project.

- Q: Billet heating furnace prices?

- The reheating furnace control mode according to the different tonnage, heating medium, price range, or recommendations according to your requirements, find good few industry units do offer the program, compared to eradicate the solution and quotation.

- Q: How are steel billets used in the production of transmission towers?

- Steel billets are used in the production of transmission towers as the raw material for manufacturing tower sections. These billets are cut, shaped, and welded to create the structural components of the towers, ensuring strength, stability, and durability in supporting electrical transmission lines.

- Q: How are steel billets used in the manufacturing of hydraulic equipment?

- Hydraulic equipment relies heavily on steel billets, which are vital in the manufacturing process. These semi-finished steel forms play a crucial role in producing hydraulic components like cylinders, valves, and pumps. To ensure the durability and performance of hydraulic equipment, the composition and quality of steel billets are carefully considered. The steel's strength, ductility, and corrosion resistance are important factors in the selection process. Once suitable steel billets are acquired, they undergo various manufacturing processes to transform them into the desired hydraulic components. For instance, the billets can be heated and forged or extruded to shape them into cylinders or valve bodies. This shaping process ensures the components meet the required dimensions, have smooth surfaces, and maintain structural integrity. Additionally, steel billets may be subjected to machining operations, such as drilling or milling, to create precise holes and intricate features. This guarantees proper fluid flow and functionality in the equipment. Furthermore, heat treatment can be applied to steel billets to enhance their mechanical properties. Annealing, quenching, or tempering processes can be utilized to achieve specific hardness, toughness, or elasticity characteristics, depending on the hydraulic equipment's requirements. In summary, steel billets serve as the raw material for manufacturing hydraulic equipment, providing the necessary strength, durability, and versatility for these critical components. Through careful selection, shaping, machining, and heat treatment, high-quality hydraulic equipment is produced, capable of withstanding the challenging conditions and pressures of various industrial applications.

- Q: Can steel billets be used in the production of mining equipment?

- Yes, steel billets can be used in the production of mining equipment. Steel billets are a common starting material for manufacturing various types of machinery and equipment, including those used in the mining industry. The high strength and durability of steel make it an ideal choice for mining equipment due to the demanding nature of mining operations. Steel billets can be forged, machined, and shaped into components or parts that are essential for mining equipment, such as gears, shafts, frames, and buckets.

- Q: Are steel billets used in the production of musical instruments?

- Certain musical instruments use steel billets in their production. Steel billets are commonly utilized as a primary component in the manufacturing of steel-string acoustic guitars. Typically, the steel billets are molded into a solid metal rod, which is then employed to construct the guitar's neck. This guarantees that the instrument possesses the necessary strength and durability to endure the tension of the steel strings. Moreover, steel billets can also be employed in the production of other metal instruments such as drums or percussion instruments, where their strength and resilience offer advantages. Nevertheless, it is important to acknowledge that the utilization of steel billets may vary depending on the specific instrument and its manufacturing process.

- Q: What are the different heat treatment processes for steel billets?

- Steel billets can undergo various heat treatment processes, each serving a specific purpose and offering distinct advantages. Among the commonly used processes are annealing, normalizing, quenching, tempering, and case hardening. 1. Annealing: The steel billets are heated to high temperatures and gradually cooled to room temperature. This process aims to reduce hardness, enhance machinability, relieve internal stresses, and refine the grain structure, resulting in a more ductile and less brittle steel. 2. Normalizing: By heating the steel billets above the critical range and cooling them in still air, the normalizing process refines the grain structure, improves mechanical properties and machinability, relieves internal stresses, and achieves uniformity in microstructure. 3. Quenching: Rapid cooling of steel billets is achieved by immersing them in a quenching medium like oil, water, or brine. Quenching transforms the austenite phase into martensite, making the steel harder and more wear-resistant. However, it may introduce residual stresses and the risk of cracking. 4. Tempering: Following quenching, tempering is often performed to reduce brittleness and enhance toughness. The quenched steel is reheated to a lower temperature and held for a specific time period. This process relieves stresses, decreases hardness, and improves ductility without sacrificing too much strength. 5. Case Hardening: This process elevates the surface hardness of steel billets while maintaining a tough and ductile core. Carburizing and nitriding are two common methods of case hardening. Carburizing involves heating the steel in a carbon-rich environment to introduce carbon into the surface. Nitriding, on the other hand, introduces nitrogen to form a hard nitride layer. These processes enhance wear resistance and prolong the lifespan of the steel billets. These heat treatment processes allow manufacturers to customize the properties of steel billets to meet specific application requirements. By carefully selecting and implementing the appropriate process, the resulting steel billets can exhibit a wide range of mechanical properties, including hardness, strength, toughness, and wear resistance.

Send your message to us

Square Shape Hot Rolled Mild Steel Billet 60mm-150mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords