Carbon Steel Billets High Quality Square Billets for construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Carbon Steel Billets High Quality Square Billets for construction

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Carbon Steel Billets High Quality Square Billets for construction

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Carbon Steel Billets High Quality Square Billets for construction

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Carbon Steel Billets High Quality Square Billets for construction

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

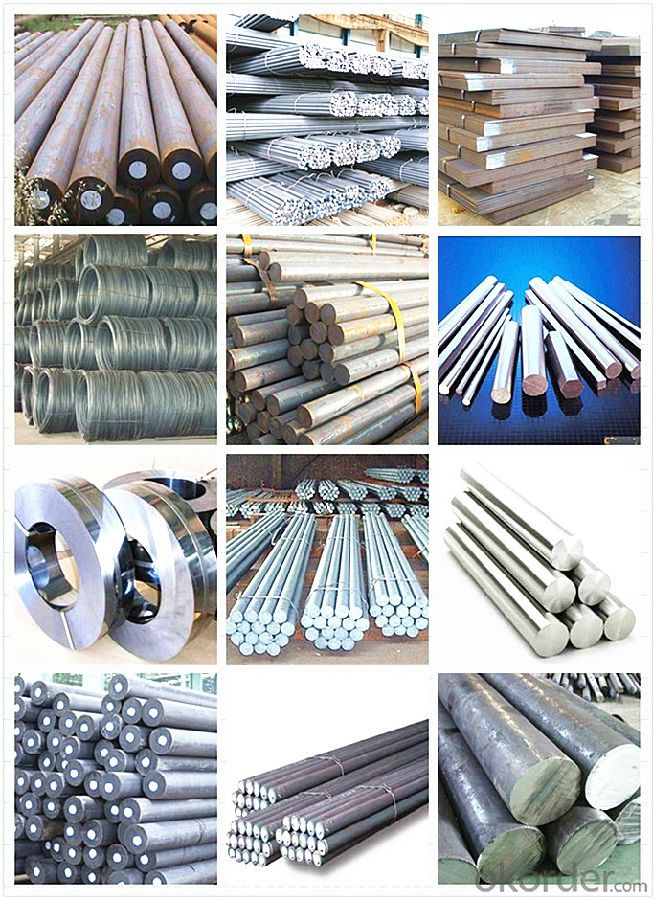

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different surface treatment methods used for steel billets?

- There are various surface treatment methods used for steel billets to enhance their properties and improve their performance. Some of the commonly used methods include: 1. Pickling: This method involves immersing the steel billets in an acid bath, typically hydrochloric or sulfuric acid, to remove any scale or oxides from the surface. Pickling helps in improving the surface finish and prepares the billets for further processing. 2. Shot blasting: In shot blasting, steel billets are subjected to high-velocity steel shots to remove any rust, scale, or contaminants from the surface. This method not only cleans the surface but also improves its roughness, promoting better adhesion of coatings or paints. 3. Phosphating: Phosphating is a chemical process that involves the application of a phosphate coating on the steel billet's surface. This coating provides corrosion resistance and improves paint adhesion. Phosphating is commonly used as a pre-treatment method before applying organic coatings. 4. Galvanizing: Galvanizing is a popular surface treatment method that involves coating the steel billets with a layer of zinc. This process provides excellent corrosion resistance and protects the steel from environmental factors. Galvanized steel billets are commonly used in outdoor applications or in industries where rust prevention is crucial. 5. Electroplating: Electroplating is a process where a thin layer of metal, such as chromium or nickel, is deposited onto the steel billet's surface using an electric current. This method improves the aesthetic appearance, corrosion resistance, and wear resistance of the steel billets. 6. Coating: Coating refers to applying a protective layer on the steel billet's surface using paints, varnishes, or other protective coatings. These coatings act as a barrier against corrosion, abrasion, and other forms of damage. Coatings can be applied through various methods like spraying, dipping, or powder coating. 7. Passivation: Passivation is a chemical process used to remove free iron and other contaminants from the steel billet's surface. This process helps in restoring the steel's passive film, which provides corrosion resistance. Passivation is commonly used in stainless steel billets to enhance their resistance to rust and corrosion. These surface treatment methods play a vital role in improving the quality, durability, and performance of steel billets, making them suitable for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: What are the main challenges in the transportation of steel billets?

- The main challenges in the transportation of steel billets include ensuring proper handling and securing of the heavy and bulky loads, preventing damage or deformation during loading and unloading processes, and complying with safety regulations for transporting hazardous materials. Additionally, factors such as limited availability of specialized equipment, fluctuations in fuel prices, and coordinating logistics for long-distance shipments can pose challenges for efficient and cost-effective transportation of steel billets.

- Q: What are the different production methods for steel billets?

- There are several different production methods for steel billets, each with its own unique characteristics and advantages. 1. Casting: One of the most common methods is the casting process, where molten steel is poured into a mold and allowed to solidify. This method can be further divided into continuous casting and ingot casting. Continuous casting involves the continuous pouring of molten steel into a water-cooled mold, which results in a continuous solidification process. Ingot casting, on the other hand, involves pouring molten steel into individual molds to create ingots that are then used as raw material for further processing. 2. Direct Reduction: Another method is the direct reduction process, which involves the reduction of iron ore in the presence of a reducing agent such as natural gas or coal. This process produces direct reduced iron (DRI), which can then be used to produce steel billets through subsequent melting and casting processes. 3. Electric Arc Furnace (EAF): The EAF method involves melting scrap steel in an electric arc furnace. This process is commonly used in recycling steel as it allows for the use of various scrap sources, including old cars, appliances, and industrial waste. The molten steel is then cast into billets or other desired shapes. 4. Basic Oxygen Furnace (BOF): The BOF method is a traditional steelmaking process that involves the conversion of molten iron from a blast furnace into steel through the injection of oxygen. This process is used for large-scale production of steel billets and offers high efficiency and flexibility in terms of raw material usage. 5. Powder Metallurgy: Powder metallurgy is an alternative method that involves compacting and sintering metal powders to create solid objects. In the case of steel billets, metal powders are compressed into the desired shape and then heated to a high temperature to achieve solidification. Each of these production methods has its own advantages and is suited for different applications and production scales. The choice of method depends on various factors including the desired properties of the steel, cost considerations, environmental impact, and availability of raw materials.

- Q: What are the key properties and characteristics of steel billets?

- Steel billets, which have a rectangular shape and typically a square cross-section, are semi-finished steel products. They serve as the initial stage for manufacturing various steel products such as bars, rods, and wire. Steel billets possess several important properties and characteristics: 1. Composition: Steel billets primarily consist of iron and carbon, with additional alloying elements incorporated to enhance specific properties. The carbon content generally ranges from 0.2% to 0.5%, depending on the desired strength and hardness. 2. Strength and Hardness: Due to their composition and heat treatment processes, steel billets offer excellent strength and hardness. This makes them suitable for applications requiring high load-bearing capacity and resistance to wear and tear. 3. Ductility: Despite their strength, steel billets also exhibit good ductility, allowing them to be easily shaped and formed into various products through processes like rolling, extrusion, and forging. This versatility enables their use in different manufacturing methods. 4. Homogeneity: Steel billets possess a uniform internal structure, ensuring consistent mechanical properties throughout the entire material. This homogeneity is achieved through precise casting and cooling processes, which minimize the presence of defects and impurities. 5. Dimensional Precision: Steel billets are manufactured with specific dimensions and tolerances, ensuring the desired size and shape for downstream processing. This dimensional precision enables efficient and accurate production, minimizing waste and maximizing productivity. 6. Surface Quality: Steel billets have a smooth and clean surface finish, free from significant imperfections or irregularities. This is crucial for subsequent processing steps, as it ensures proper bonding during welding, machining, or coating operations. 7. Heat Conductivity: Steel billets exhibit excellent thermal conductivity, efficiently transferring heat during various manufacturing processes like hot rolling or continuous casting. This property ensures uniform heating and cooling, resulting in consistent material properties. 8. Corrosion Resistance: Steel billets are prone to corrosion if left unprotected. However, they can be coated or treated with anti-corrosive measures to enhance their resistance to rust and other forms of degradation. In summary, steel billets are characterized by their strength, ductility, dimensional precision, and homogeneity. These properties make them a critical raw material in the steel industry, facilitating the production of high-quality steel products used in diverse sectors such as construction, automotive, and infrastructure.

- Q: What are the common uses of steel billets?

- Steel billets are commonly used in the production of various steel products such as bars, rods, wire, pipes, and structural components. They serve as the raw material for further processing and shaping, making them essential in industries like construction, manufacturing, and infrastructure development.

- Q: How are steel billets used in the production of structural steel sections?

- Steel billets are used as a primary raw material in the production of structural steel sections. These billets are heated and then passed through a series of roller mills to shape them into various structural profiles such as beams, channels, angles, and columns. The hot rolling process helps to improve the strength and durability of the steel, making it suitable for construction purposes.

- Q: How do steel billets contribute to the manufacturing of HVAC equipment?

- Steel billets are an essential raw material in the manufacturing of HVAC equipment because they serve as the base material for various components such as ductwork, frames, and structural supports. The high strength and durability of steel billets make them suitable for withstanding the demanding operating conditions of HVAC systems. Additionally, steel billets can be easily shaped and formed into intricate designs, allowing manufacturers to create complex components that optimize the efficiency and performance of HVAC equipment.

- Q: How are steel billets used in the manufacturing of power transmission equipment?

- Power transmission equipment relies heavily on steel billets, solid blocks of steel that serve as vital raw materials. These billets are essential for the production of various parts and components. One key application of steel billets lies in the manufacturing of gears and shafts, which play a critical role in power transmission. Gears facilitate the transfer of rotational motion between components, while shafts are responsible for transmitting both motion and torque. To withstand the high forces and speeds associated with power transmission, steel billets are forged and machined into durable and robust gears and shafts. Moreover, steel billets are also utilized in the creation of structural elements like housings and frames. These components offer support and protection to internal mechanisms, ensuring the smooth operation of equipment. By employing techniques such as forging, cutting, and welding, steel billets are transformed into sturdy structures that can handle the intricate arrangements and dynamic forces present in power transmission systems. In conclusion, the significance of steel billets in the production of power transmission equipment cannot be overstated. They are integral in the fabrication of gears, shafts, and structural components, which are essential for the reliable and efficient operation of power transmission systems. The strength, durability, and precision of steel billets contribute significantly to the overall performance and longevity of such equipment.

- Q: How are steel billets used in the manufacturing of oil and gas pipelines?

- Steel billets are of utmost importance when it comes to the production of oil and gas pipelines. They serve as the primary material from which pipes are derived. Essentially, steel billets are partially finished forms of steel that are cast into specific shapes and sizes for further processing. In order to manufacture oil and gas pipelines, the initial step involves melting steel scrap and other alloys in a furnace to create molten steel. This liquid metal is then poured into molds or continuous casting machines to produce steel billets. These billets usually have a cylindrical shape and can vary in length and diameter depending on the desired specifications of the pipeline. After the steel billets have cooled down and solidified, they undergo various shaping processes, such as hot rolling or extrusion, to transform them into seamless or welded pipes. Hot rolling entails passing the billets through a series of rollers that apply pressure and heat in order to shape them into the desired pipe form. On the other hand, extrusion involves forcing the billets through a die to create the pipe shape. The resulting pipes then undergo further processing through techniques like heat treatment, machining, and coating to enhance their strength, durability, and resistance to corrosion. These processes ensure that the pipes can endure the harsh conditions and pressures encountered in the oil and gas industry. All in all, steel billets play a critical role in the production of oil and gas pipelines as they supply the starting material for creating the pipes. Their strength, versatility, and ability to withstand extreme conditions make them the ideal choice for constructing pipelines that transport oil and gas over long distances.

- Q: How are steel billets used in the production of forged parts?

- Steel billets are used in the production of forged parts as they serve as the starting material for the forging process. The billets are heated to a specific temperature and then shaped into the desired form by applying pressure or impact using a forging press or hammer. This process enhances the strength and durability of the steel, resulting in high-quality forged parts that are used in various industries such as automotive, aerospace, and construction.

Send your message to us

Carbon Steel Billets High Quality Square Billets for construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords