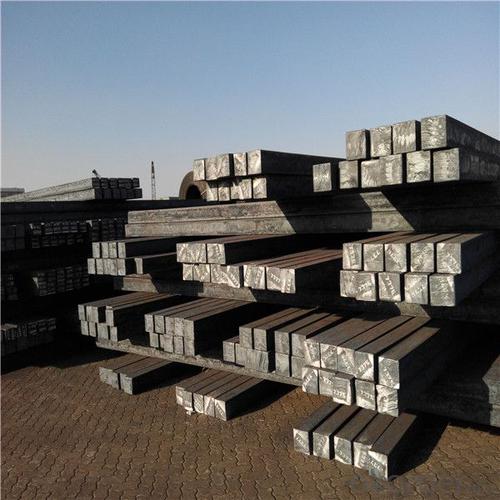

Hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16021 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet :

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

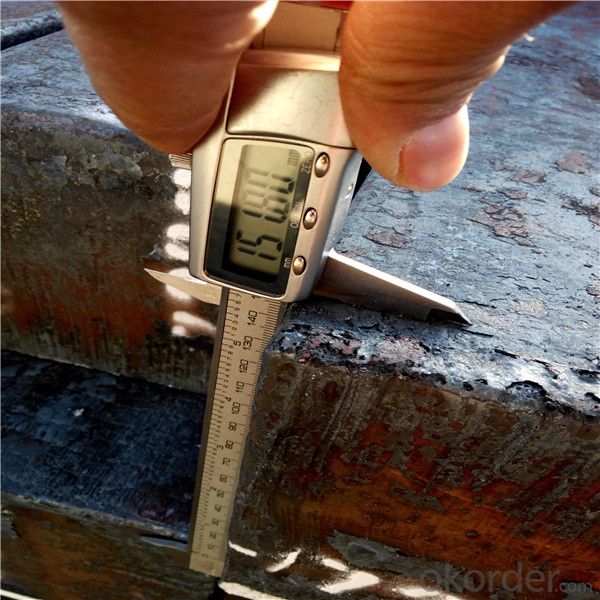

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the potential applications of steel billets in the medical industry?

- Steel billets have several potential applications in the medical industry. They can be used for the manufacturing of medical instruments, such as surgical tools, implants, and prosthetics, due to their strength, durability, and corrosion resistance. Steel billets can also be utilized in the production of medical equipment and machinery, such as MRI machines and X-ray tables, as they provide structural support and stability. Additionally, steel billets can be used for the fabrication of medical furniture and fixtures, like hospital beds and surgical tables, ensuring reliability and long-lasting performance in healthcare settings.

- Q: Can steel billets be used in the production of kitchenware?

- Kitchenware can indeed be made using steel billets. Steel billets, which are essentially unfinished steel products that have been cast into a rectangular shape, can undergo further processing through methods such as forging, rolling, or extrusion. These processes allow for the creation of a wide range of kitchenware items, including pots, pans, utensils, and cutlery. The use of steel in kitchenware production is popular due to its exceptional strength, durability, and resistance to heat. It is also well-known for its ability to resist corrosion, making it safe for contact with food and liquids. Furthermore, steel is easy to clean and maintain, making it a hygienic choice for kitchenware. The typical manufacturing process involves heating and shaping the steel billets into the desired form, followed by finishing processes like polishing or coating to improve both the aesthetics and functionality of the kitchenware. With the versatility to produce kitchenware in various shapes, sizes, and designs, steel billets provide a flexible solution for creating high-quality and long-lasting kitchenware items.

- Q: What are the main applications of steel billets?

- Steel billets are semi-finished products that are used in various applications across different industries. The main applications of steel billets include: 1. Construction: Steel billets are commonly used in the construction industry for the production of structural steel. They are used to manufacture beams, columns, and other load-bearing elements in buildings and infrastructure. Steel billets provide strength, durability, and high load-bearing capacity, making them ideal for construction projects. 2. Manufacturing: Steel billets are also used in the manufacturing industry for the production of various metal products. They are often used as raw materials for the manufacturing of pipes, tubes, rods, wires, and other metal components. Steel billets can be easily shaped and formed into different sizes and shapes, making them versatile for manufacturing purposes. 3. Automotive Industry: Steel billets are extensively used in the automotive industry for the production of various components and parts. They are used to manufacture engine parts, chassis components, suspension systems, and other critical automotive components. Steel billets offer excellent mechanical strength and heat resistance, making them suitable for demanding automotive applications. 4. Machinery and Equipment: Steel billets are also utilized in the machinery and equipment industry. They are used to manufacture gears, shafts, bearings, and other components that require high strength and durability. Steel billets can withstand heavy loads and provide excellent resistance to wear and tear, making them essential for machinery and equipment manufacturing. 5. Energy and Oil Industry: In the energy and oil industry, steel billets are widely used for the production of pipes and tubes. They are utilized in the construction of pipelines for transporting oil, gas, and other fluids over long distances. Steel billets provide the required strength, corrosion resistance, and pressure containment necessary for such applications. Overall, steel billets are crucial in various industries due to their excellent mechanical properties, versatility, and ability to be shaped into different forms. Their applications range from construction and manufacturing to automotive, machinery, and energy industries, contributing to the development and growth of multiple sectors.

- Q: How are steel billets used in the production of transmission towers?

- Transmission towers require steel billets, which are semi-finished steel products, as a crucial component for their production. The first step in the process is to heat the steel billets in a furnace at extremely high temperatures. This hot rolling process softens the billets and makes them more malleable, enabling easy shaping and forming into the desired structure of the transmission tower. Once heated, the billets are then passed through rolling mills, where they are shaped into long, cylindrical sections known as steel bars. These bars are further processed and cut to the required length and dimensions based on the specific design and requirements of the transmission tower. Following the shaping and cutting, the steel bars undergo galvanization, which involves coating them with a protective layer of zinc. This zinc coating provides corrosion resistance, safeguarding the tower from environmental elements like moisture and rust. Finally, the galvanized steel bars are assembled and welded together to create the intricate framework of the transmission tower. The usage of strong and durable steel billets ensures that the tower can withstand heavy loads and extreme weather conditions. In conclusion, steel billets are essential for the production of transmission towers due to their strength, flexibility, and corrosion resistance. Their ability to be shaped and formed into the desired dimensions, along with their durability, make them an ideal material for constructing transmission towers.

- Q: How do steel billets contribute to the corrosion resistance of a product?

- Steel billets, which are semi-finished steel products, contribute to the corrosion resistance of a final product by providing a high-quality base material. Steel billets are made from steel alloys that contain specific elements such as chromium, nickel, and molybdenum, which enhance the corrosion resistance properties of the steel. These alloying elements form a protective layer on the surface of the steel, known as a passive film, which prevents or slows down the corrosion process by acting as a barrier against corrosive agents. Additionally, the composition and processing of steel billets can be tailored to meet specific requirements, allowing for the production of corrosion-resistant products suitable for various applications.

- Q: How do steel billets contribute to the infrastructure development sector?

- Steel billets play a crucial role in the infrastructure development sector by serving as the foundation for various construction projects. These billets are used to produce structural steel products, such as beams, columns, and reinforcement bars, which are essential components in building bridges, highways, buildings, and other infrastructure projects. The strength and durability of steel billets make them ideal for withstanding heavy loads and adverse weather conditions, ensuring the long-term stability and safety of structures. Moreover, their versatility allows for easy fabrication and customization, enabling engineers and architects to design innovative and efficient solutions for infrastructure development. Overall, steel billets provide the necessary strength, reliability, and flexibility to support the growth and sustainability of the infrastructure development sector.

- Q: How do steel billets contribute to the overall vibration resistance of a structure?

- Steel billets, due to their specific characteristics, significantly contribute to the overall vibration resistance of a structure. First and foremost, steel is a very dense and rigid material, which means that it possesses a high natural frequency. This high natural frequency allows steel billets to absorb and dissipate the energy generated by external vibrations more effectively than other materials. Moreover, steel billets have excellent damping properties. Damping refers to the ability of a material to reduce the amplitude of vibrations over time. Steel billets, being highly dense and rigid, are able to absorb and dissipate vibrations quickly, preventing them from propagating throughout the structure. This helps in reducing the overall vibration levels and, subsequently, increasing the overall vibration resistance of the structure. Furthermore, steel billets possess high tensile strength and stiffness, which allow them to resist deformation under dynamic loads. This means that when subjected to vibration forces, steel billets are able to maintain their shape and structural integrity, minimizing the risk of failure or damage. The high tensile strength of steel also enables it to withstand the impact of external forces without undergoing significant deformation or permanent damage. In addition, steel billets can be designed and manufactured to specific dimensions and shapes, allowing for precise integration into various structural components. This ensures that the steel billets are optimally positioned within the structure, enhancing their vibration resistance capabilities. Overall, steel billets contribute to the overall vibration resistance of a structure by effectively absorbing and dissipating vibrations, resisting deformation, and maintaining their structural integrity. Through these properties, steel billets help to minimize the impact of external vibrations and ensure the longevity and stability of the structure.

- Q: What is the role of steel billets in the manufacturing of railway wheels?

- Steel billets are the starting material used in the manufacturing of railway wheels. They are heated and forged into the desired shape and dimensions, forming the solid base for the wheels. The billets undergo various processes such as rolling, machining, and heat treatment to ensure the wheels have the necessary strength, durability, and dimensional accuracy required for railway applications.

- Q: Can steel billets be used in the production of industrial equipment?

- Industrial equipment can indeed utilize steel billets. These semi-finished metal products can undergo further processing to produce a wide range of industrial equipment, including machinery, tools, automotive parts, construction materials, and more. Steel's exceptional strength, durability, and adaptability make it the perfect material for manufacturing industrial equipment. By shaping, machining, and welding steel billets, intricate structures and components can be created, ensuring the necessary strength and stability for industrial applications. Furthermore, heat treatment can be applied to steel billets to enhance their mechanical properties, making them even more suitable for heavy-duty industrial equipment.

- Q: How are steel billets used in the production of mining equipment?

- Steel billets are used in the production of mining equipment as they serve as the raw materials for various components such as gears, shafts, and structural frames. These billets are shaped, machined, and welded to create strong and durable parts that can withstand the harsh conditions of mining operations.

Send your message to us

Hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16021 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords