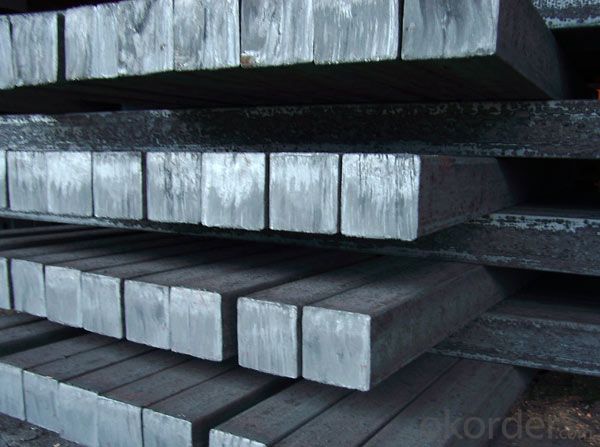

Steel Rectangle Billet Bars Raw Material for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Rectangle Billet Bars Raw Material for Sale with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Rectangle Billet Bars Raw Material for Sale are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Rectangle Billet Bars Raw Material for Sale are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different quality standards for steel billets?

- There are several quality standards for steel billets which are used to assess the overall quality and suitability of the material for various applications. Some of the prominent quality standards include: 1. ASTM A615/A615M: This standard specifies the requirements for deformed and plain carbon-steel bars for concrete reinforcement. It covers billets used in the production of reinforcing bars with specific mechanical properties and dimensional tolerances. 2. ASTM A706/A706M: This standard outlines the requirements for low-alloy steel used in the production of reinforcing bars. It specifies the chemical composition, mechanical properties, and dimensional tolerances of the billets. 3. EN 10025-2: This European standard specifies the requirements for non-alloy structural steels. It covers billets used in the production of various structural elements, such as beams, columns, and plates. The standard defines the chemical composition, mechanical properties, and technical delivery conditions of the steel billets. 4. JIS G3112: This Japanese industrial standard covers steel bars for concrete reinforcement. It outlines the chemical composition, mechanical properties, and tolerances for billets used in the production of reinforcing bars. 5. GB/T 699: This Chinese standard specifies the quality requirements for carbon structural steels. It defines the chemical composition, mechanical properties, and technical delivery conditions of steel billets used in various structural applications. These quality standards ensure that steel billets meet specific criteria for strength, durability, and dimensional accuracy. Adhering to these standards guarantees that the steel billets are of high quality and suitable for their intended use in construction, manufacturing, and reinforcement applications.

- Q: How are steel billets used in the manufacturing of slabs?

- Steel billets are an essential raw material used in the manufacturing of slabs. Slabs are large, flat pieces of steel that are used as a primary input in various industries, such as construction, automotive, and manufacturing. To produce slabs, the first step involves obtaining steel billets. These billets are semi-finished steel products that are typically obtained through the continuous casting process or by hot-rolling ingots. They are solid, rectangular or square-shaped blocks of steel with a cross-sectional area that can vary depending on the desired size and thickness of the slabs. Once the steel billets are obtained, they are heated to a high temperature to make them more malleable and easier to shape. This process, known as hot rolling, involves passing the billets through a series of rolling mills to progressively reduce their thickness and increase their length. The rolling mills apply intense pressure to the billets, causing them to elongate and acquire the desired dimensions. During the hot rolling process, the steel billets are often subjected to various manipulations, such as reheating and cooling, to ensure proper shaping and metallurgical properties. The billets may also go through additional processes, such as descaling (removing the oxide layer) and surface treatment, to enhance their quality and finish. Once the hot rolling process is completed, the steel billets are transformed into slabs. These slabs are then further processed to meet specific requirements. For instance, they may undergo additional rolling or reheating processes to achieve the desired thickness, dimensions, and surface finish. The slabs can also be cut into smaller pieces or further processed into different steel products, such as plates, sheets, or coils, depending on the intended use. In summary, steel billets play a crucial role in the manufacturing of slabs. They serve as the starting point for the production process, undergoing hot rolling and other treatments to transform them into the desired shape, size, and quality. The resulting slabs are then used as a primary input in various industries, contributing to the production of a wide range of steel products.

- Q: How is the demand for steel billets projected to change in the future?

- The demand for steel billets is expected to experience significant changes in the future due to various factors. One of the primary drivers of this change is the overall growth of the construction and infrastructure sectors. As economies continue to develop, there will be an increased need for steel billets to support the construction of buildings, bridges, roads, and other infrastructure projects. Additionally, the automotive industry is also anticipated to contribute to the changing demand for steel billets. With the rising demand for electric vehicles and the need for lightweight materials to improve fuel efficiency, steel billets may be replaced by alternative materials such as aluminum or carbon fiber in certain automotive applications. Furthermore, the renewable energy sector is another potential factor that could impact the demand for steel billets. As the world moves towards cleaner energy sources, there will be a growing requirement for wind turbines and solar panels, which are predominantly made from steel. This could lead to an increase in demand for steel billets in the manufacturing of these renewable energy components. On the other hand, advancements in technology and manufacturing processes may also influence the demand for steel billets. As new techniques and materials are developed, there is a possibility of steel billets being substituted by alternative materials or manufacturing methods that offer superior performance or cost-efficiency. Overall, while the demand for steel billets is expected to remain strong in the foreseeable future, it may undergo changes based on the growth of construction, infrastructure, automotive, and renewable energy sectors, as well as advancements in technology and materials.

- Q: How are steel billets used in the production of construction parts?

- Steel billets are used in the production of construction parts as they serve as the raw material for various manufacturing processes. These billets are heated and then shaped into different forms such as beams, columns, and rods through processes like rolling and forging. The resulting construction parts are strong, durable, and capable of withstanding the structural demands of buildings and infrastructure projects.

- Q: How are steel billets used in the manufacturing of machinery?

- Steel billets are used in the manufacturing of machinery as a primary raw material. They are heated and shaped into various components, such as gears, shafts, and structural frames, which are then assembled to create the machinery. The high strength and durability of steel billets make them ideal for withstanding heavy loads and harsh working conditions, ensuring the reliability and longevity of the machinery.

- Q: Can steel billets be used in high-temperature applications?

- Yes, steel billets can be used in high-temperature applications. Steel billets are typically made from carbon steel, which has good heat resistance properties. Carbon steel can withstand elevated temperatures without significant deformation or loss in strength. However, it is important to consider the specific grade and composition of the steel billets as different alloys may have varying temperature limits. Additionally, factors such as the duration of exposure to high temperatures, the presence of corrosive environments, and the mechanical loading conditions should be taken into account when determining the suitability of steel billets for high-temperature applications.

- Q: How are steel billets used in the production of railway tracks?

- Steel billets are the raw materials used in the production of railway tracks. They are heated, shaped, and rolled to form long, flat bars known as rails. These rails are then laid on the trackbed, forming the foundation for the tracks on which trains run.

- Q: What are the properties of high-quality steel billets?

- High-quality steel billets are sought after for their desirable properties in various applications. Chiefly, these billets boast a high degree of purity, containing minimal impurities like sulfur, phosphorus, and other non-metallic elements. This purity contributes to the overall strength and performance of the steel. Another crucial property of high-quality steel billets is their uniform internal structure. This means that the grains within the billet are evenly distributed, resulting in consistent mechanical properties throughout the material. This uniformity enhances the steel's strength, toughness, and durability. High-quality steel billets also demonstrate excellent dimensional accuracy. They possess precise and consistent dimensions, which are vital for subsequent processing and manufacturing operations. This dimensional accuracy ensures that the billets can be easily formed, rolled, forged, or machined into their intended final shapes. Moreover, high-quality steel billets exhibit a superior surface finish. They are devoid of defects like cracks, voids, or inclusions on their surfaces. This smooth and defect-free surface allows for better heat transfer, improved corrosion resistance, and an enhanced aesthetic appearance of the final steel products. Lastly, high-quality steel billets showcase excellent metallurgical properties. They possess a well-controlled chemical composition, which determines their specific mechanical and physical characteristics. These properties can be tailored to meet the requirements of different applications, such as high strength, high ductility, or resistance to extreme temperatures. To summarize, high-quality steel billets possess properties such as purity, uniform internal structure, dimensional accuracy, excellent surface finish, and desirable metallurgical properties. These properties make them ideal for a wide range of applications, including the construction, automotive, aerospace, and manufacturing industries.

- Q: What industries use steel billets?

- Steel billets are widely used in various industries due to their strength, durability, and versatility. Some of the main industries that heavily rely on steel billets include construction, automotive, manufacturing, and energy. In the construction industry, steel billets are used for the production of structural components such as beams, columns, and girders. These components provide the necessary strength and support in buildings, bridges, and other infrastructure projects. The automotive industry utilizes steel billets for the manufacturing of various car parts, including engine components, chassis, and suspension systems. Steel billets are preferred in this industry due to their high strength-to-weight ratio, which improves fuel efficiency and overall performance. Manufacturing industries, such as machinery, equipment, and tool production, also heavily rely on steel billets. They are used to manufacture gears, shafts, valves, and other critical components that require high strength, durability, and precision. Furthermore, steel billets are essential in the energy sector, particularly in the production of oil and gas pipelines. These pipelines require steel billets of specific grades to withstand harsh conditions, high pressures, and corrosive environments. In addition to these main industries, steel billets find applications in other sectors such as shipbuilding, aerospace, mining, and agriculture. They are widely used wherever strength, durability, and reliability are crucial. Overall, steel billets have a diverse range of applications across various industries, thanks to their exceptional mechanical properties. The demand for steel billets remains strong, as they are an essential raw material in the production of critical components in numerous sectors.

- Q: What are the different surface defects that can occur in steel billets?

- Steel billets can suffer from a variety of surface defects. Among the most common are: 1. Scale: During heating, a rough, flaky oxide layer known as scale can form on the billet's surface. This coating can negatively impact the final product's quality. 2. Cracks: Thermal stress, improper handling, or excessive cooling can cause cracks to appear on the billet's surface. These cracks can be either longitudinal or transverse and compromise the overall structural integrity of the billet. 3. Decarburization: High temperatures or chemical reactions can lead to the reduction of carbon content at the steel's surface, a process known as decarburization. This weakens the outer layer, affecting the billet's mechanical properties. 4. Pits: Corrosion, inadequate cleaning, or chemical reactions can result in small depressions or cavities on the billet's surface, known as pits. Pits can reduce strength and create localized stress concentrations. 5. Surface roughness: Improper handling, insufficient machining, or poor surface finishing can leave steel billets with uneven or rough surfaces. This can impact the final product's appearance and performance. 6. Inclusions: Non-metallic materials become trapped in the steel during manufacturing, forming inclusions. They can appear as dark spots, streaks, or irregular shapes on the billet's surface. Inclusions weaken the steel and decrease its ductility. 7. Surface contamination: Handling or storage can introduce foreign materials like dirt, oil, or grease to steel billets, leading to surface defects, corrosion, or compromised quality. Detecting and addressing these surface defects early in the manufacturing process is crucial to ensure high-quality steel billets. Various inspection techniques, including visual examination, ultrasonic testing, and magnetic particle inspection, can be used to identify and mitigate these defects.

Send your message to us

Steel Rectangle Billet Bars Raw Material for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords