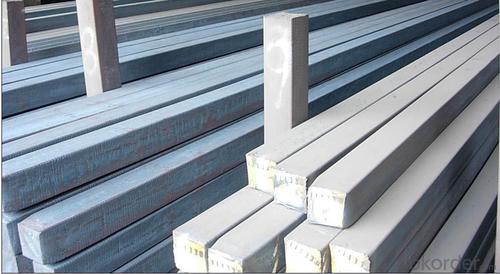

Square Steel Billet Q235 Grade Prime Quality 4#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 4#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 4#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 4#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 4#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 4#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be used in the automotive industry?

- The automotive industry makes use of steel billets, which are semi-finished steel products. These billets are typically further processed into different shapes and forms. In automotive manufacturing, steel billets are commonly utilized for producing various components like engine parts, transmission parts, chassis components, and suspension systems. This choice offers several benefits such as high strength, durability, and cost-effectiveness. Moreover, steel billets can be easily shaped, machined, and welded to meet specific design requirements and performance standards in the automotive sector. As a result, steel billets play a crucial role in automobile production, contributing significantly to the overall performance, safety, and reliability of vehicles.

- Q: How are steel billets used in the manufacturing of forgings?

- Steel billets are an essential raw material in the manufacturing of forgings. These billets, which are semi-finished steel products, are used as the starting point for shaping and forming various types of forgings. The process begins with the selection of appropriate steel billets based on their chemical composition and mechanical properties. The billets are typically made from high-quality carbon or alloy steel and are carefully inspected to ensure their suitability for the desired end product. Once the billets are selected, they undergo a series of heating and shaping operations. The billets are heated to a specific temperature, known as the forging temperature, in a furnace to make them more malleable. This temperature is carefully controlled to ensure optimal plasticity and minimize any potential defects. After reaching the forging temperature, the billets are transferred to a forging press or hammer. These powerful machines apply immense pressure to shape the billet into the desired form. The force exerted by the press or hammer causes the billet to deform and take on the shape of the die or mold being used. The forged billet may undergo several additional steps, such as trimming, piercing, or machining, to achieve the final desired shape. These steps are necessary to remove any excess material or refine the forged part further. Throughout the manufacturing process, the quality of the steel billets plays a crucial role in determining the final quality of the forgings. The billets must have consistent chemical composition, mechanical properties, and freedom from defects. This ensures that the forged parts have the desired strength, durability, and dimensional accuracy. In summary, steel billets are used in the manufacturing of forgings as the initial material that undergoes heating, shaping, and other processes to create the final forged part. The quality of the billets directly impacts the quality of the forgings, making the selection and inspection of billets a critical step in the overall manufacturing process.

- Q: How are steel billets used in the production of steel cables?

- Steel billets are an integral component in the production of steel cables. These billets serve as the raw material from which the cables are made. To produce steel cables, the billets undergo a series of processes. Firstly, the steel billets are heated in a furnace to extremely high temperatures, which makes them malleable and easier to work with. This process is known as annealing. The billets are then passed through a series of rollers to shape them into the desired form and size for the cables. Next, the shaped billets are passed through a wire drawing machine where they are pulled through a series of dies to reduce their diameter and increase their length. This results in a wire-like structure known as a wire rod. These wire rods are then further processed through a series of machines to clean and remove any impurities or surface defects. They are then coated with lubricants to reduce friction during the subsequent processes. The wire rods are then passed through a wire stranding machine, where multiple wires are twisted together to form strands. These strands are then combined together, either by twisting or braiding, to form the final steel cables. The cables are once again coated with lubricants to improve their durability and resistance to corrosion. Overall, steel billets play a crucial role in the production of steel cables as they serve as the starting material for the entire process. Through a series of heating, shaping, and drawing processes, the billets are transformed into wire rods, which are then further processed to create the strands and eventually the final steel cables.

- Q: How are steel billets used in the production of agricultural components?

- Steel billets are an essential raw material used in the production of various agricultural components. These billets serve as the starting point for the manufacturing process, where they are transformed into a wide range of agricultural components such as plows, harrows, tillers, cultivators, and seeders. The steel billets are first melted down and cast into a solid form, typically a rectangular or square shape, with a consistent cross-section. This solid piece of steel is then heated and rolled into the desired shape and size required for the specific agricultural component being produced. Once the billets have been rolled and shaped, they undergo further processes such as cutting, drilling, bending, and welding to form the final agricultural component. These components are designed to withstand the demanding conditions of the agricultural industry, including exposure to harsh weather, heavy loads, and frequent use. Steel billets offer several advantages in the production of agricultural components. Firstly, steel is a strong and durable material, providing the necessary strength and resilience required for agricultural machinery to operate effectively. Additionally, steel is highly resistant to corrosion, ensuring that the agricultural components can withstand exposure to moisture, fertilizers, and other chemicals commonly used in farming. Furthermore, steel billets can be easily customized and fabricated into different shapes and sizes, allowing for the production of a wide variety of agricultural components that cater to specific farming needs. The versatility of steel billets also enables manufacturers to create components with intricate designs and features, enhancing their functionality and performance. In conclusion, steel billets play a crucial role in the production of agricultural components. The versatility, strength, and durability of steel make it an ideal material for manufacturing machinery and equipment used in the agricultural industry. By starting with steel billets and transforming them through various manufacturing processes, agricultural components are created that can withstand the demanding conditions of farming and contribute to the efficiency and productivity of agricultural operations.

- Q: What are the different types of cleaning methods used for steel billets?

- There are several different types of cleaning methods used for steel billets, depending on the specific requirements and desired outcome. Some of the common cleaning methods for steel billets include: 1. Acid cleaning: This method involves the use of acid solutions to remove surface contaminants, such as rust, scale, and grease. Acid cleaning is effective in removing stubborn stains and corrosion, but it requires careful handling and proper disposal of the acidic waste products. 2. Shot blasting: Shot blasting is a mechanical cleaning method that uses high-speed projectiles to impact the surface of the steel billets. This process helps remove rust, scale, and other surface impurities, leaving a clean and smooth finish. Shot blasting is commonly used for large-scale cleaning operations and can be automated for efficiency. 3. Pickling: Pickling is a chemical cleaning method that involves immersing the steel billets in an acid solution, usually hydrochloric acid or sulfuric acid. This process removes oxide layers and other impurities from the surface, resulting in a clean and corrosion-resistant finish. 4. Ultrasonic cleaning: Ultrasonic cleaning uses high-frequency sound waves to agitate a cleaning solution, creating microscopic bubbles that help dislodge dirt, grease, and contaminants from the surface of the steel billets. This method is effective for removing fine particles and can reach areas that are difficult to clean by other methods. 5. Electrolytic cleaning: Electrolytic cleaning utilizes an electric current to remove surface impurities from the steel billets. The billets are immersed in an electrolyte solution, and the application of a direct current causes the impurities to be attracted to an electrode, effectively cleaning the surface. 6. Chemical cleaning: Chemical cleaning involves the use of specialized chemicals to dissolve or react with surface contaminants, such as rust, oil, or paint. Different chemicals are used depending on the type of contaminant and the desired outcome. Chemical cleaning is effective for removing organic and inorganic substances from the steel billets. Overall, these different cleaning methods offer various approaches to achieve a clean and smooth surface for steel billets, ensuring their quality and suitability for further processing or applications.

- Q: How are steel billets stored and transported?

- Steel billets, which are used for further processing, are carefully stored and transported to maintain their quality and safety. In terms of storage, steel billets are kept in designated areas within steel plants or warehouses, equipped with proper ventilation, drainage, and protection from the elements. They are organized in stacks with enough space between them for easy accessibility and inspection. To maximize space, steel billets are often stored vertically in racks or on specially designed shelves. This allows for easy handling and transportation. When it comes to transportation, heavy-duty equipment such as cranes or forklifts are used to move the billets safely, minimizing the risk of damage or injury. Chains or straps are used to secure the billets and prevent movement during transit. For longer distance transportation, steel billets are loaded onto trucks, trains, or ships. Containers or trailers are chosen based on the size and weight of the billets to ensure stability and safety. Proper weight distribution is crucial to maintain balance and prevent accidents. During transportation, it is important to protect the billets from moisture, extreme temperatures, and other external factors that could affect their quality. This may involve covering them with tarpaulins or using specialized containers. In conclusion, steel billets are stored and transported with great care to maintain their integrity and quality. Proper storage methods and suitable environmental conditions prevent damage and deterioration. Heavy-duty equipment and secure transportation minimize the risk of accidents. By following these practices, steel billets can be safely stored and transported, ready for further processing in the steel industry.

- Q: How are steel billets used in the manufacturing of construction materials?

- The manufacturing of construction materials relies heavily on steel billets, which are a necessary raw material. These semi-finished forms of steel serve as the initial stage for various construction products, including rebars, beams, columns, and plates. During the production process, steel billets undergo heating and are then passed through a series of rolling mills to achieve the desired shape. For example, when producing rebars, the billet is heated and rolled into long, slim bars of different diameters. These rebars are commonly used in construction to reinforce concrete structures, ensuring their durability and strength. Likewise, steel billets are utilized in the creation of beams, columns, and plates, which are essential elements in building construction. Beams provide structural support, while columns bear the weight of the structure and transmit loads to the foundation. Plates, on the other hand, find applications in flooring, walls, and roofing. The utilization of steel billets in construction materials offers numerous benefits. Steel, renowned for its high strength-to-weight ratio, provides exceptional structural integrity, resulting in more efficient and cost-effective construction. Furthermore, steel is highly ductile, allowing it to be easily shaped and molded into various forms, enabling versatility in design and construction. Additionally, steel is a durable material that exhibits excellent resistance to environmental factors like corrosion and fire. Consequently, steel construction materials have a long lifespan and are suitable for a wide range of applications, including high-rise buildings, bridges, and infrastructure projects. In conclusion, steel billets play a vital role in the manufacturing of construction materials. By being transformed into rebars, beams, columns, and plates, these billets provide the necessary strength, durability, and versatility required in the construction industry.

- Q: How are steel billets used in the manufacturing of bearings?

- The production of bearings involves the use of steel billets, which are indispensable raw materials. Bearings, mechanical parts that facilitate smooth movement between two components, require steel billets, solid blocks of steel, to be heated and forged into the desired shape and dimensions. This forging process involves applying high pressure to the heated billets, resulting in plastic deformation and the creation of a rough bearing shape. After the initial forging, the rough-shaped billets undergo additional precision machining processes to refine their dimensions and improve their surface finish. These processes, including turning, grinding, and polishing, ensure that the final product meets the necessary specifications for optimal bearing performance. Once the billets are machined to the appropriate size and shape, they undergo heat treatment to enhance their mechanical properties. Heat treatment involves subjecting the billets to specific temperatures and durations to achieve the desired hardness, strength, and durability. This process may involve various steps, such as quenching, tempering, and annealing, depending on the desired characteristics of the bearing. Following heat treatment, the steel billets are now ready for the final stage of the bearing manufacturing process: assembly. The billets are carefully inspected for defects or imperfections before being assembled with other bearing components, such as inner and outer rings, rolling elements, and cages. These components are meticulously matched and assembled to ensure the desired performance and load-bearing capacity of the bearing. In conclusion, steel billets play a pivotal role in the manufacturing of bearings. They undergo forging, machining, heat treatment, and assembly to create high-quality bearings capable of withstanding various loads and providing smooth movement in a wide array of applications.

- Q: Reasons and treatment methods of billet stripping in continuous casting

- even two cold regions can be uniformly cooled, due to uneven thickness of shell, caused by the inconsistent temperature, the shell shrinkage is still uneven, and also there will be the development of. Therefore, the selection of unqualified mold is the main reason causing the removal. Secondly, the cooling effect of the two cooling zone can not be ignored.

- Q: What is the cost of producing steel billets?

- The cost of producing steel billets can vary depending on various factors such as the quality of the raw materials used, the production process employed, and the market conditions. Generally, the cost of producing steel billets includes several components. Firstly, the cost of raw materials, which typically include iron ore, coal or coke, and other alloying elements. The prices of these materials can fluctuate based on global market dynamics and availability. Secondly, the cost of energy is a significant factor in steel billet production. This includes the cost of electricity and fuel required for the manufacturing process, such as powering the blast furnaces or electric arc furnaces used to melt the raw materials. Thirdly, labor costs play a crucial role in the overall cost of production. This includes wages for skilled and unskilled workers involved in operating the machinery, maintaining equipment, and overseeing the production process. Additionally, there are indirect costs that need to be considered, such as maintenance and repair expenses for machinery, transportation costs for raw materials and finished products, and overhead costs related to administrative functions. It is important to note that the cost of producing steel billets can also be influenced by external factors like government regulations, tariffs, and taxes. Furthermore, market demand and competition can impact pricing strategies and ultimately affect production costs. Therefore, providing an exact cost figure for producing steel billets is challenging as it is subject to constant fluctuations. It is best to consult industry experts or steel manufacturers for the most accurate and up-to-date information on production costs.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 4#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords