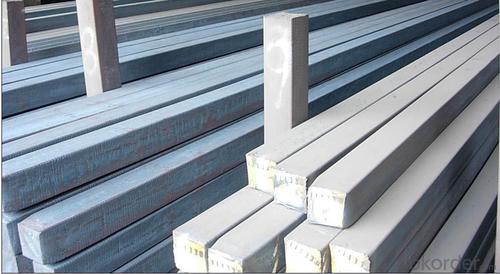

Square Steel Billet Q235 Grade Prime Quality 7#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 7#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 7#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 7#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 7#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 7#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Are there any international standards for steel billets?

- Yes, there are international standards for steel billets. The most commonly recognized standards for steel billets include ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Standards). These standards ensure the quality, composition, and dimensions of steel billets, promoting consistency and compatibility in international trade and manufacturing processes.

- Q: 100Q235 steel can only be rolled from billets of Q235?Or a billet can be rolled into Q195~Q215 and other models of steel?Is there a detailed classification of billets? Do you have GB?

- Billet classification of GB, it is convenient to check

- Q: How are steel billets used in the production of transmission towers?

- Steel billets are used in the production of transmission towers as the raw material for manufacturing tower sections. These billets are cut, shaped, and welded to create the structural components of the towers, ensuring strength, stability, and durability in supporting electrical transmission lines.

- Q: Can steel billets be heat treated for increased hardness?

- Indeed, it is possible to enhance the hardness of steel billets through heat treatment. The process involves subjecting the steel billets to a particular temperature and subsequently cooling them at a rapid or gradual pace, depending on the desired hardness. This procedure is commonly employed to enhance the mechanical properties of steel, including hardness, strength, and resistance to wear. Several heat treatment methods exist that can be utilized to augment the hardness of steel billets. One prevalent technique is referred to as quenching and tempering. During this process, the steel billets are heated to a high temperature, typically surpassing their critical temperature, and promptly cooled by immersing them in a fluid medium, like oil or water. The rapid cooling induces the steel to harden. However, the steel may become excessively brittle in this state, necessitating tempering by reheating it to a lower temperature. This tempering process mitigates brittleness and heightens the toughness of the steel while preserving its hardness. Another heat treatment method that can be employed to enhance hardness is called case hardening. This technique entails altering the composition of the steel surface to establish a hardened outer layer while maintaining a softer core. Case hardening is typically accomplished by introducing carbon or nitrogen into the surface of the steel billets through processes like carburizing or nitriding. Subsequently, the steel billets are heated to a specific temperature and held for a designated period, permitting the carbon or nitrogen to permeate the steel. This engenders a hardened surface layer, endowing the steel with increased hardness and wear resistance while upholding the core's toughness. In summary, heat treatment can be employed to heighten the hardness of steel billets. The specific heat treatment method chosen will rely on the desired level of hardness, along with other mechanical properties necessary for the steel's intended application.

- Q: How are steel billets used in the production of gear blanks?

- Steel billets are an essential component in the production of gear blanks. Gear blanks are the starting point for the manufacturing of gears. They are essentially the raw, unfinished pieces that will later be shaped and transformed into the final gear product. Steel billets, which are long, rectangular bars of steel, provide the necessary material for the creation of gear blanks. These billets are typically made from high-quality steel that possesses the required strength, durability, and machinability characteristics needed for gear production. To create gear blanks, the steel billets are first heated to a specific temperature to make them more malleable and easier to shape. The heated billets are then subjected to various forming processes, such as forging or extrusion, to transform them into the desired shape of the gear blank. Once the gear blank is formed, it undergoes further machining processes to refine its shape, dimensions, and surface finish. This may include operations such as turning, milling, drilling, or grinding. The precise machining ensures that the gear blank meets the required specifications for the final gear product. The gear blanks produced from steel billets serve as the foundation for the creation of various types of gears, such as spur gears, helical gears, bevel gears, or worm gears. These gear blanks undergo additional steps, such as heat treatment and surface hardening, to enhance their mechanical properties and increase their resistance to wear and fatigue. In summary, steel billets are integral to the production of gear blanks as they provide the raw material from which gears are formed. Through a series of heating, forming, and machining processes, the steel billets are transformed into gear blanks, which are then further processed to create the final gears used in various applications.

- Q: Can steel billets be used in the production of consumer electronics?

- No, steel billets are primarily used in the production of construction materials and machinery, rather than consumer electronics which typically require more specialized materials such as semiconductors, plastics, and alloys.

- Q: What are the different types of cutting methods used for steel billets?

- There are several different types of cutting methods used for steel billets, including sawing, shearing, flame cutting, and water jet cutting.

- Q: What are the main factors affecting the creep resistance of steel billets?

- The creep resistance of steel billets is determined by several main factors, including temperature, stress level, and alloy composition. Temperature plays a crucial role in determining the material's resistance to creep deformation. As the temperature increases, the atomic diffusion becomes more active, leading to enhanced creep deformation. Higher temperatures can also result in the formation of voids and cracks, weakening the billet's resistance to creep. The stress level applied to the steel billet also significantly affects its creep resistance. Higher stresses promote dislocation movement within the crystal lattice, increasing the rate of creep. Additionally, stress concentration at defects like voids or impurities can accelerate creep deformation. Therefore, it is crucial to control the stress level to maintain the billet's creep resistance. The alloy composition of the steel billet is another critical factor that influences its creep resistance. Different alloying elements can alter the material's microstructure, impacting its creep properties. For example, elements like chromium, molybdenum, and vanadium can form stable carbides that hinder dislocation movement and improve creep resistance. On the other hand, elements like sulfur or phosphorus can promote grain boundary sliding and reduce creep resistance. To enhance the creep resistance of steel billets, manufacturers must carefully control temperature, stress level, and alloy composition. By doing so, they can ensure that the billets are suitable for various applications.

- Q: What is the difference between steel billets and steel bars?

- Steel billets and steel bars are both semi-finished products made from steel, but there are some key differences between them. Firstly, steel billets are typically larger in size compared to steel bars. Billets are usually square or rectangular in shape and have a cross-sectional area of around 36 to 216 square inches. They are often produced through a process called continuous casting, where molten steel is poured into molds and then cooled and solidified. Billets serve as the starting material for various steel products, including bars, rods, and wire. On the other hand, steel bars are smaller in size and have a more standardized shape. They can be round, square, hexagonal, or flat, depending on their intended use. Steel bars are usually produced through a process called hot rolling, where billets are heated and passed through a series of rolling mills to achieve the desired shape and dimensions. Bars are often used in construction, manufacturing, and other industries where strength and durability are required. Another difference between steel billets and steel bars lies in their surface finish. Steel billets usually have a rough, mill-scale surface due to the casting process. In contrast, steel bars have a smoother surface finish, which is achieved through hot rolling and subsequent finishing processes such as peeling, grinding, or polishing. Additionally, while steel billets are primarily used as raw material for further processing, steel bars are the final product that can be directly used in various applications. Steel bars are commonly used in construction projects, as reinforcement in concrete structures, in the production of machinery, tools, and automotive parts, and in many other industrial applications. In summary, the main differences between steel billets and steel bars lie in their size, shape, surface finish, and purpose. Billets are larger, rougher, and serve as the starting material for various steel products, while bars are smaller, have a smoother surface finish, and are the final product used in a wide range of applications.

- Q: What is the cost of producing steel billets?

- The cost of producing steel billets can vary depending on various factors such as the quality of raw materials, energy costs, labor expenses, equipment maintenance, and market demand. It is difficult to provide a specific cost without considering these variables, but it generally involves substantial investment in machinery, infrastructure, and operational expenses.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 7#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords