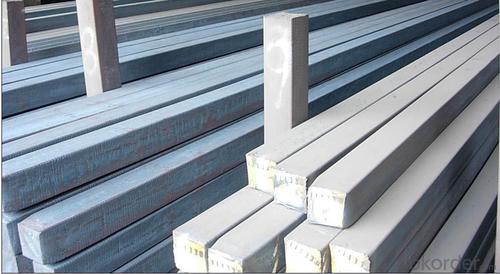

Square Steel Billet Q235 Grade Prime Quality 3#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 3#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 3#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 3#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 3#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 3#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the production of agricultural components?

- Steel billets are used in the production of agricultural components by being shaped and formed into various parts such as blades, shafts, and brackets, which are then used in machinery and equipment for farming and agriculture. These components are known for their strength, durability, and ability to withstand harsh conditions, making them essential in the agricultural industry.

- Q: What are the potential applications of steel billets in the medical sector?

- The medical sector has a wide range of potential applications for steel billets. One key use is in the manufacturing of medical instruments and surgical tools. Steel's high strength and durability make it an ideal material for producing precise and reliable instruments. Scalpels, forceps, bone saws, and orthopedic implants are just a few examples of the various medical tools that can be made from steel billets and are essential for surgeries and procedures. Moreover, steel billets can be utilized in the production of medical equipment like hospital beds, wheelchairs, and stretchers. These products require a strong and robust material to ensure patient safety and comfort. Steel provides the necessary strength to support the weight of patients and withstand regular usage, making it an excellent choice for these applications. Additionally, steel billets can be used in the construction of medical facilities and infrastructure. Steel is renowned for its structural integrity, making it suitable for building hospitals, clinics, and research laboratories. Steel structures offer resistance against earthquakes, fires, and other natural disasters, ensuring the safety of both medical personnel and patients. Furthermore, steel billets can be employed in the manufacturing of medical storage systems and cabinets. These storage solutions are crucial for maintaining a sterile and organized environment, preventing cross-contamination, and ensuring the proper storage of medical supplies and equipment. To sum up, steel billets have extensive potential in the medical sector. Steel's strength, durability, and reliability make it an invaluable material for enhancing patient care and safety, whether it's through the production of surgical instruments, medical equipment, construction of medical facilities, or manufacturing of medical storage solutions.

- Q: What are the different types of steel billet defects?

- There are various types of steel billet defects, including surface defects like cracks, laps, and scars, as well as internal defects such as segregation, porosity, and inclusions.

- Q: What are the different types of steel billet cutting tools?

- There are several different types of steel billet cutting tools available, each designed for specific purposes and applications. Some of the most common types include: 1. Bandsaw: This type of cutting tool uses a continuous loop of toothed blade to cut through steel billets. Bandsaws are versatile and can be used for both straight and curved cuts. 2. Circular saw: Circular saws feature a toothed blade that rotates in a circular motion to cut through steel billets. They are known for their speed and efficiency, making them a popular choice for large-scale cutting operations. 3. Abrasive cut-off saw: These tools use a high-speed rotating abrasive disc to cut through steel billets. Abrasive cut-off saws are ideal for cutting through thick and hard materials quickly. 4. Plasma cutter: Plasma cutters use a high-velocity jet of ionized gas to melt and cut through steel billets. They are known for their precision and ability to cut through thick materials with ease. 5. Waterjet cutter: Waterjet cutters use a high-pressure jet of water mixed with abrasive particles to cut through steel billets. This type of cutting tool is highly accurate and does not generate heat, making it suitable for cutting heat-sensitive materials. 6. Laser cutter: Laser cutters use a high-powered laser beam to melt and vaporize steel, creating a precise and clean cut. Laser cutting is known for its high level of accuracy and versatility. These are just a few examples of the different types of steel billet cutting tools available. The choice of tool depends on factors such as the type and thickness of the material being cut, the desired level of precision, and the specific application requirements.

- Q: How does the quality of steel billets affect the quality of the final product?

- Determining the quality of the final steel product heavily relies on the quality of steel billets. Steel billets are semi-finished products that undergo a continuous casting process to serve as raw materials for downstream steel products. To begin with, the chemical composition of steel billets greatly affects the quality of the end product. Steel is primarily an alloy of iron and carbon, with additional elements like manganese, chromium, nickel, and others. The presence and precise amount of these alloying elements in the billets have a significant impact on the properties of the final steel, including strength, hardness, ductility, and corrosion resistance. Any variation or deviation in the chemical composition of the billets can lead to undesired changes in the characteristics of the final product. Furthermore, the physical properties of steel billets, including their size, shape, and internal structure, directly influence the quality of the final steel product. The dimensions and geometry of the end product are determined by the size and shape of the billets, ensuring proper fit and functionality. Moreover, the absence of defects like cracks, voids, or inclusions in the internal structure of the billets is crucial for producing high-quality steel products. Imperfections in the billets can propagate and cause failures, compromising the strength and overall quality of the final product. Additionally, the quality of the final steel product is influenced by the manufacturing process of the steel billets. Factors such as cooling rate, casting speed, and temperature control during the continuous casting process can affect the microstructure and overall homogeneity of the billets. Proper control and optimization of the process are necessary to ensure that the billets possess the desired metallurgical properties, such as a uniform grain structure and the absence of segregation or impurities. Moreover, the quality of steel billets directly impacts the efficiency and cost-effectiveness of subsequent steel processing operations. High dimensional accuracy in the billets reduces the need for excessive material removal during machining or shaping processes, resulting in higher material yield, reduced waste, and improved overall productivity. In conclusion, the quality of steel billets significantly influences the quality of the final steel product. The chemical composition, physical properties, and manufacturing process of the billets all play vital roles in determining the characteristics of the end product. By ensuring high-quality steel billets, manufacturers can produce steel products that meet industry standards, possess desired mechanical properties, and exhibit superior performance in various applications.

- Q: How are steel billets used in the production of railway infrastructure?

- The production of railway infrastructure relies heavily on steel billets, which are crucial for creating various railway components such as rails, sleepers, and fasteners. These semi-finished steel products undergo a hot rolling process to shape them into long and narrow sections with consistent cross-sections, serving as the foundation for railway tracks. Rails, one of the primary uses of steel billets in railway infrastructure, are formed from the processed billets. These rails, available in different lengths and dimensions, provide stability and a sturdy platform for trains to run on. The strength and durability of steel ensure that the tracks can withstand heavy loads and frequent traffic. Steel billets are also used to manufacture sleepers, which act as horizontal supports for the rails. Concrete or wooden sleepers are created from the shaped and formed billets and are laid on the track bed to maintain the alignment and gauge of the tracks. Sleepers play a vital role in distributing the weight of trains and providing stability. Furthermore, steel billets are essential in producing fasteners like bolts, nuts, and clips. These fasteners secure the rails to the sleepers, ensuring that they remain in position during train operations. Steel's strength and resilience make it a reliable material for these critical components, which must withstand significant stress and vibrations. In conclusion, steel billets are indispensable in the production of railway infrastructure. Their versatility and strength make them suitable for creating rails, sleepers, and fasteners, which are vital for a reliable and robust railway system. Without steel billets, the construction and maintenance of railway tracks would be impossible, impacting the efficiency and safety of train operations.

- Q: How are steel billets used in the production of oil and gas equipment?

- Steel billets are used in the production of oil and gas equipment as they serve as the raw material for manufacturing various components such as pipes, valves, fittings, and other structural parts. These billets undergo further processing, such as hot rolling or forging, to form the desired shape and strength required for the specific equipment. The use of steel billets ensures the durability, strength, and corrosion resistance needed to withstand the demanding conditions of the oil and gas industry.

- Q: How are steel billets used in the production of agricultural machinery?

- Steel billets are used in the production of agricultural machinery as a raw material for various components such as gears, shafts, and frames. These billets are melted and molded into the desired shape, providing the necessary strength and durability required for the machinery to effectively perform tasks in the agricultural sector.

- Q: What are the main factors affecting the creep resistance of steel billets?

- The main factors affecting the creep resistance of steel billets are temperature, stress level, and alloy composition. Temperature plays a crucial role in determining the creep resistance of steel billets. As the temperature increases, the atomic diffusion within the material becomes more active, leading to enhanced creep deformation. Higher temperatures allow for more rapid grain growth and can result in the formation of voids and cracks, ultimately weakening the billet's resistance to creep. The stress level applied to the steel billet also significantly affects its creep resistance. Higher stresses increase the rate of creep, as they promote dislocation movement within the crystal lattice. Additionally, stress concentration at various defects, such as voids or impurities, can accelerate creep deformation. Therefore, controlling the stress level is essential in maintaining the creep resistance of steel billets. The alloy composition of the steel billet is another critical factor influencing its creep resistance. Different alloying elements can alter the microstructure of the material, affecting its creep properties. For example, elements like chromium, molybdenum, and vanadium can form stable carbides that hinder dislocation movement and improve creep resistance. Other elements, such as sulfur or phosphorus, can promote grain boundary sliding and reduce creep resistance. In summary, the creep resistance of steel billets is primarily influenced by temperature, stress level, and alloy composition. By carefully controlling these factors, manufacturers can produce steel billets with enhanced creep resistance, ensuring their suitability for various applications.

- Q: What are the different types of heat treatment processes used for steel billets?

- There are several different types of heat treatment processes used for steel billets. Some commonly used methods include annealing, normalizing, quenching and tempering, and case hardening. Each process has its own purpose and is used to achieve specific properties in the steel billets.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 3#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords