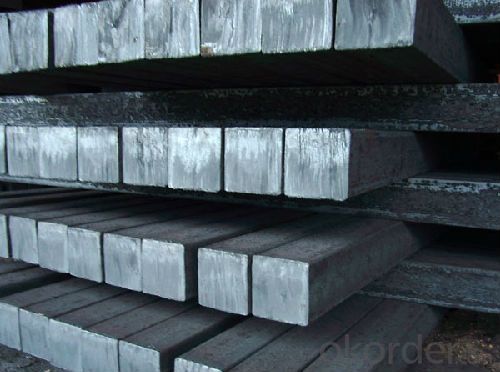

Square Steel Billet, Square Bar, Prime Steel Billet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Steel Billet, Square Bar, Prime Steel Billet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Square Steel Billet, Square Bar, Prime Steel Billet are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Square Steel Billet, Square Bar, Prime Steel Billet are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195/Q235/Q275/20MnSi/3SP/5SP

Certificates: ISO, SGS, BV

size:60*60/90*90/100*100/120*120/150*150

Length: 6m/12m,

Packaging: Export packing, nude packing, bundled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q:What are the different types of tests conducted on steel billets?

- There are several types of tests conducted on steel billets, including visual inspection, dimensional inspection, chemical composition analysis, mechanical testing, ultrasonic testing, and magnetic particle inspection. These tests are crucial to ensure the quality and integrity of the steel billets before they are further processed and used in various applications.

- Q:Which is good for pure iron billet?

- If you would like to consult more detailed information, I suggest you choose Shanghai far west special steel products Co., ltd..

- Q:What are the different types of steel billet welding processes?

- There are several different types of steel billet welding processes that are commonly used in various industries. These processes include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW involves a flux-coated electrode that is manually fed into the welding pool. It is a versatile and widely used process for welding steel billets. 2. Gas Metal Arc Welding (GMAW): This process, commonly known as MIG welding, uses a continuously fed wire electrode and a shielding gas to protect the weld pool. It is a popular method for welding steel billets due to its efficiency and ease of use. 3. Flux-Cored Arc Welding (FCAW): FCAW is similar to GMAW, but it uses a tubular electrode filled with flux instead of a solid wire. This process is often preferred for outdoor or windy conditions as the flux provides better protection against atmospheric contamination. 4. Submerged Arc Welding (SAW): SAW involves feeding a consumable electrode and a granular flux into the weld zone, while the arc remains submerged beneath a layer of flux. It is commonly used for welding large steel billets due to its high deposition rates and deep penetration capabilities. 5. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a shielding gas to protect the weld pool. It is a precise and high-quality welding process suitable for thin steel billets or applications that require exceptional weld aesthetics. 6. Electroslag Welding (ESW): ESW is a highly efficient process used for welding thick steel billets. It involves melting a consumable electrode and the base metal in a molten slag pool, which provides protection and acts as a filler material. 7. Laser Beam Welding (LBW): LBW utilizes a high-energy laser beam to melt and join steel billets together. It is a precise and fast welding process commonly used in industries such as automotive and aerospace. Each of these welding processes has its own advantages and limitations, and the choice of process depends on factors such as the type and thickness of the steel billet, desired weld quality, production requirements, and cost considerations.

- Q:How are steel billets used in the manufacturing of mining equipment?

- Steel billets are used in the manufacturing of mining equipment as they serve as the starting material for various components. These billets are first heated and then shaped into desired forms such as gears, shafts, or frames, which are crucial for the construction of heavy-duty mining machinery. The strength and durability of steel make it an ideal choice for withstanding the harsh conditions and rigorous demands of mining operations.

- Q:What are the different methods of surface inspection for steel billets?

- There are several methods of surface inspection for steel billets, which are used to identify any defects or irregularities on the surface. These methods include visual inspection, magnetic particle inspection, liquid penetrant inspection, ultrasonic inspection, and eddy current inspection. Visual inspection is the simplest and most commonly used method, where inspectors visually examine the surface of the billets for any visible defects such as cracks, pits, or surface irregularities. This method relies on the expertise and experience of the inspector. Magnetic particle inspection involves the use of magnetic fields and magnetic particles to detect surface and near-surface defects. A magnetic field is applied to the steel billet, and magnetic particles are applied to the surface. If there is a defect, the magnetic particles will be attracted to it, making the defect visible under proper lighting. Liquid penetrant inspection is another method used to detect surface defects. In this method, a liquid penetrant is applied to the surface of the billet. The penetrant seeps into any surface defects, and after a certain amount of time, excess penetrant is removed. A developer is then applied, which draws the penetrant out of the defects, making them visible. Ultrasonic inspection involves the use of high-frequency sound waves to detect internal and surface defects. A transducer is used to emit sound waves into the billet, and the reflected waves are analyzed to identify any defects. This method can detect defects such as cracks, voids, and inclusions. Eddy current inspection is a non-destructive testing method that uses electromagnetic induction to detect surface defects. A probe is moved over the surface of the billet, and an alternating current is passed through it. Any surface irregularities or defects will disrupt the flow of current, which can be detected and analyzed. Each of these methods has its own advantages and limitations, and the choice of method depends on the specific requirements and constraints of the inspection process. By utilizing these different methods, manufacturers can ensure the quality and reliability of steel billets before they are further processed or used in various applications.

- Q:What are the different surface defects found in stainless steel billets?

- There are several different surface defects that can be found in stainless steel billets. Some of the common surface defects include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of stainless steel during the heating process. It appears as a dark, rough layer and can be easily removed by pickling or passivation. 2. Pitting: Pitting is localized corrosion that appears as small, shallow pits on the surface of the billet. It is caused by chloride ions or other aggressive chemicals and can lead to reduced corrosion resistance. 3. Scratches: Scratches can occur during handling, transportation, or processing of the billet. They are visible as linear marks on the surface and can affect the appearance and integrity of the material. 4. Lamination: Lamination defects occur as thin layers or flakes parallel to the surface of the billet. They are caused by improper rolling or inadequate bonding during the manufacturing process. 5. Inclusions: Inclusions are non-metallic particles or impurities that are embedded in the stainless steel billet. They can affect the mechanical properties and corrosion resistance of the material. 6. Decarburization: Decarburization is the loss of carbon from the surface of the billet during heating. It appears as a light-colored layer and can negatively impact the material's strength and hardness. 7. Cracks: Cracks can occur due to thermal stresses, improper cooling, or mechanical damage. They can be either surface cracks or internal cracks, and can significantly weaken the billet. It is important to detect and address these surface defects to ensure the quality and performance of stainless steel billets in various applications.

- Q:How are steel billets used in the production of axles?

- Steel billets are used in the production of axles as a starting material. They are heated and shaped through forging or rolling processes to form the desired axle shape. This ensures the axle has the necessary strength and durability to support the weight and withstand the forces experienced during operation.

- Q:How do steel billets contribute to the defense industry?

- The defense industry heavily relies on steel billets, which are crucial for manufacturing various defense equipment and vehicles. These semi-finished steel products serve as a starting point for further processing and shaping into specific components. Armored vehicles, in particular, benefit from steel billets as they require high levels of protection against ballistic attacks and explosive devices. The armor plates and panels, which provide the necessary strength and resilience to these vehicles, are manufactured using steel billets. Furthermore, steel billets find application in the production of different weapon systems, including firearms, artillery guns, and missiles. The strength and durability of steel make it the ideal material for constructing critical components such as barrels and chambers. Steel's ability to withstand high temperatures and pressures is vital for ensuring the reliable and efficient performance of these defense systems. Steel billets also play a crucial role in the manufacturing of naval vessels, submarines, and aircraft carriers. These military ships and submarines require steel components that can endure the harsh marine environment, including corrosion, impact, and extreme temperatures. Steel billets are employed to produce these components, guaranteeing the structural integrity and longevity of these vessels. In conclusion, steel billets are indispensable to the defense industry as they provide the essential raw material for manufacturing a wide range of defense equipment. Their strength, durability, and versatility make them ideal for producing armored vehicles, weapon systems, naval vessels, and other defense-related components. By contributing to the production of these crucial assets, steel billets play a vital role in enhancing national defense capabilities.

- Q:How are steel billets used in the manufacturing of bars?

- Steel billets are used in the manufacturing of bars by being heated and then rolled or forged into specific shapes and sizes. This process ensures the bars have the desired strength, durability, and dimensional accuracy required for various applications in industries such as construction, automotive, and infrastructure.

- Q:What are the potential applications of steel billets in the aerospace aftermarket?

- The aerospace aftermarket offers a wide range of potential applications for steel billets. These applications encompass the production of various aerospace components, including engine parts, airframe structures, landing gear components, and fasteners. One possible use of steel billets in the aerospace aftermarket is for manufacturing engine parts. Critical components like turbine blades, compressor discs, and shafts can be produced using steel billets. These parts require high strength, durability, and resistance to extreme temperatures, all of which can be achieved through the utilization of steel billets. Additionally, steel billets can be employed to manufacture exhaust system components like manifolds and flanges, which also require high temperature resistance. Another significant application of steel billets in the aerospace aftermarket is in the production of airframe structures. Steel billets can be utilized to manufacture various structural components, including beams, frames, and brackets. These components are essential for providing strength and stability to the aircraft's fuselage, wings, and other structural elements. Steel billets offer the necessary strength-to-weight ratio, corrosion resistance, and fatigue resistance required for these demanding applications. Furthermore, steel billets have the potential to be used in the production of landing gear components in the aerospace aftermarket. Landing gear plays a critical role in the safe operation of an aircraft, and it must withstand significant loads and stresses during takeoff, landing, and taxiing. Steel billets can be machined into landing gear parts such as axles, struts, and wheels, which require high strength, toughness, and fatigue resistance. Lastly, steel billets find applications in the production of fasteners used in the aerospace aftermarket. Essential for joining various components together in an aircraft, fasteners such as bolts, screws, and nuts are vital for secure connections. Steel billets can be forged or machined into high-strength fasteners capable of withstanding the high loads and vibrations experienced during flight. In summary, the aerospace aftermarket offers numerous potential applications for steel billets. From engine parts to airframe structures, landing gear components, and fasteners, steel billets provide the necessary properties required for the demanding aerospace industry, including strength, durability, temperature resistance, and fatigue resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Steel Billet, Square Bar, Prime Steel Billet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords