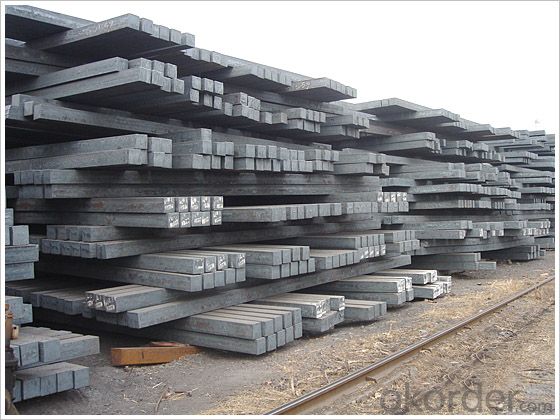

High quality steel billet product Q195 Q35

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1) Suitable for making various strong cutting tool abrasion resistance, impact resistance.

2) Used to produce all kinds of high hard and super hard saw blade, drill, tap, broach, gear hob and various kinds of milling cutter.

3) Used for advanced punching die, screw die, and the toughness and complicated shape of the punch, etc.

4) Is used for cold forging die and drawing mode, etc.

5) Recommended watchcase factory, screw factory and other cold stamping products industry use.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard: GB,

-Grade: Q195 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

Measures of HR Square Bar (small measures):

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

7 | 0.385 | 22 | 3.80 |

8 | 0.502 | 24 | 4.52 |

9 | 0.636 | 25 | 4.91 |

10 | 0.785 | 26 | 5.30 |

11 | 0.950 | 28 | 6.15 |

12 | 1.13 | 30 | 7.06 |

13 | 1.33 | 32 | 8.04 |

14 | 1.54 | 34 | 9.07 |

15 | 1.77 | 36 | 10.17 |

16 | 2.01 | 38 | 11.24 |

17 | 2.27 | 40 | 12.56 |

18 | 2.54 | 42 | 13.85 |

19 | 2.82 | 45 | 15.90 |

20 | 3.14 | 48 | 18.09 |

21 | 3.46 | 50 | 19.63 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Can stainless steel rust?

A1: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: What are the potential applications of steel billets in the automotive aftermarket?

- Steel billets have a wide range of potential applications in the automotive aftermarket. These applications can be primarily attributed to the strength, durability, and versatility of steel as a material. Firstly, steel billets can be used in the production of various automotive parts, such as engine components, transmission parts, suspension systems, and chassis components. Due to its high tensile strength and resistance to wear and tear, steel billets can provide the necessary structural integrity and longevity required in these critical automotive components. Additionally, steel billets can be used in the manufacturing of customized or aftermarket modifications for vehicles. These modifications can include performance upgrades, such as engine tuning, exhaust systems, and suspension modifications. Steel billets can be machined and formed into the desired shapes and sizes, allowing for precise customization and improved performance. Furthermore, steel billets can be utilized in the production of automotive tools and equipment used in the aftermarket. These tools can include jacks, stands, wrenches, and other specialized equipment required for repairs, maintenance, and modifications. The use of steel billets ensures that these tools are strong, durable, and capable of withstanding the demanding conditions of the automotive industry. Moreover, steel billets can be employed in the manufacturing of aftermarket body parts and accessories. These can range from exterior components such as bumpers, grilles, and fenders, to interior accessories like shift knobs, pedals, and trim pieces. Steel billets can be shaped, welded, and finished to meet the desired specifications and aesthetics of the vehicle owner, providing a wide range of options for customization. Overall, the potential applications of steel billets in the automotive aftermarket are vast and diverse. From critical engine components to performance upgrades, tools, and body modifications, steel billets offer the necessary strength, durability, and versatility required in the automotive industry.

- Q: What are the different surface treatments for improved surface lubrication in steel billets?

- Some of the different surface treatments for improved surface lubrication in steel billets include hot rolling, cold rolling, pickling, and applying a lubricant coating.

- Q: What are the main factors that affect the availability of steel billets?

- The main factors that affect the availability of steel billets include the demand and consumption patterns in the steel industry, the production capacity and efficiency of steel mills, fluctuations in raw material prices, government policies and regulations, and global economic conditions.

- Q: How are steel billets marked for identification and traceability?

- Various methods are utilized to mark steel billets for identification and traceability. One prevalent approach involves the utilization of unique identification numbers or codes. These numbers or codes can be engraved or stamped onto the billet's surface, enabling easy identification. Laser engraving machines or steel stamping tools are frequently employed for this purpose. Aside from identification numbers, other significant details, such as the grade, heat number, and production date, can also be marked on the billet. These details play a crucial role in traceability, allowing for the tracking of the steel's origin and quality. Moreover, some manufacturers may choose to employ additional marking techniques, such as paint or ink marking. This may entail the use of specific colors or symbols to represent different characteristics or attributes of the billet. For example, a particular color might indicate the intended use of the steel, while a symbol may signify the manufacturer's logo or quality certification. Overall, the marking of steel billets for identification and traceability is indispensable in ensuring quality control, verifying compliance with industry standards, and facilitating efficient inventory management throughout the supply chain.

- Q: Billet heating furnace prices?

- Billet heating furnace as non-standard series equipment, the price is not very fixed. Equipment is different, the price is not the same, in general, you need to find a few better units within the family to do the program offer, according to the program and quote contrast.

- Q: How are steel billets recycled?

- Steel billets undergo the process of steel billet recycling, wherein they are collected from different sources like manufacturing plants, construction sites, and scrap yards. These collected billets are then transported to a recycling facility where they go through a series of steps to become new steel products. The initial step in steel billet recycling involves sorting and cleaning. The collected billets are sorted based on their size, shape, and quality, and any impurities or foreign materials are eliminated during this stage. Once the billets are sorted and cleaned, they are prepared for the next step in the recycling process. The subsequent step is melting, in which the cleaned steel billets are melted down in a furnace at extremely high temperatures. This melting process helps in separating any remaining impurities and enables the steel to be shaped into new forms. The molten steel is then poured into molds or cast into different shapes according to the desired end product. Once the steel has cooled and solidified, it undergoes further processing to achieve the desired specifications. This may include rolling, forging, or extruding the steel billets to create various steel products like bars, rods, or sheets. These newly formed steel products are then thoroughly inspected for quality and undergo rigorous testing to ensure they meet industry standards. The final step in steel billet recycling is distribution and usage. The recycled steel products are transported to various industries such as construction, automotive, or manufacturing, where they are utilized to create a wide range of products. By recycling steel billets, we can reduce the demand for raw materials, conserve energy, and minimize environmental impact. In conclusion, the process of steel billet recycling involves sorting, cleaning, melting, shaping, and distributing. This recycling process allows us to reuse steel billets and transform them into new steel products, thereby contributing to a more sustainable and environmentally friendly approach to steel production.

- Q: What are the main challenges in the distribution of steel billets?

- The overall efficiency and effectiveness of the steel billet distribution process can be impacted by several challenges. These challenges include: 1. Logistics and transportation pose a difficulty due to the weight and size of steel billets. Specialized equipment and handling are necessary, making transportation challenging, particularly in remote areas or regions with poor infrastructure. Coordinating transportation modes, scheduling, and ensuring timely delivery adds complexity to the task. 2. Storage and inventory management present challenges as steel billets often need to be stored before further distribution or processing. Proper storage facilities with adequate capacity and suitable conditions, such as temperature control and protection from moisture, are crucial. Managing inventory levels to avoid excess or shortage is also a key challenge. 3. Quality control is essential to maintain the quality of steel billets throughout the distribution process. Any damage or contamination during handling or transportation can affect the final steel products' properties and performance. Implementing strict quality control measures, inspections, and monitoring processes is crucial to meet desired quality standards. 4. Market fluctuations and demand forecasting are challenging due to factors like economic conditions, construction activities, and geopolitical events. Accurate demand forecasting is crucial, as failure to predict demand accurately can lead to excess inventory or stockouts, resulting in financial losses. 5. Environmental regulations and sustainability requirements impose challenges. Compliance with environmental regulations, such as emissions control and waste management, can be challenging in the distribution process. Utilizing eco-friendly transportation methods and exploring sustainable packaging options can help address these challenges. 6. Global competition and pricing pressures affect steel billet distribution. Constant analysis and adaptation to market trends, competitor behavior, and price fluctuations are necessary for steel producers and distributors. Maintaining competitive pricing while ensuring profitability is a significant challenge in the steel billet distribution business. To overcome these challenges, coordination among various stakeholders in the supply chain is essential. This includes steel manufacturers, distributors, logistics providers, and end-users. Continuous improvement, technological advancements, and effective communication are crucial to mitigate these challenges and optimize the distribution of steel billets.

- Q: How are steel billets used in the manufacturing of gears and bearings?

- Steel billets are an essential raw material in the manufacturing process of gears and bearings. These billets are semi-finished steel products that are typically cast into a square or rectangular shape. They serve as the starting point for producing various components used in gears and bearings. In the case of gears, steel billets are first cut into smaller sections to create gear blanks or rough gear shapes. These blanks are then further processed through a series of operations like forging, machining, and heat treatment. Forging involves shaping the gear blank using compressive forces, which enhances the mechanical properties of the steel and aligns the grain structure for better strength. Machining is then used to remove excess material, refine the shape, and create the gear teeth. Finally, heat treatment is applied to improve the hardness, toughness, and wear resistance of the gear. Similarly, in the manufacturing of bearings, steel billets are transformed into various components such as inner and outer rings, balls or rollers, and cages. The billets are first cut and shaped into rough rings, which are then further processed through machining operations to achieve the desired dimensions and precision. The rings are often subjected to heat treatment to enhance their hardness, improve surface finish, and increase resistance to wear and fatigue. The balls or rollers are also produced from steel billets through a similar process, while cages are typically fabricated separately using sheet metal. Overall, steel billets play a crucial role in the manufacturing of gears and bearings. They serve as the foundation material that undergoes various shaping, machining, and heat treatment processes to create the final components with the required strength, durability, and precision. The quality of the steel billets used greatly influences the performance and longevity of gears and bearings, making them a critical aspect of the entire manufacturing process.

- Q: What are the different types of steel billet surface treatment defects?

- Some common types of steel billet surface treatment defects include pitting, scaling, decarburization, scratches, and cracks.

- Q: How are steel billets used in the manufacturing of machine parts?

- Steel billets are an essential raw material in the manufacturing of machine parts. These billets are solid, semi-finished steel products that are cast into specific shapes and sizes. The process of using steel billets involves various stages. Firstly, the steel billets are heated in a furnace to a specific temperature, which softens the metal and makes it more malleable. Once the billets reach the desired temperature, they are ready for further processing. Next, the heated billets are transferred to a rolling mill, where they undergo a process called hot rolling. In this process, the billets are passed through a series of rollers, which apply pressure and shape them into desired forms such as bars, rods, or sheets. The hot rolling process ensures that the steel billets achieve the required dimensions and surface finish. After hot rolling, the shaped steel billets are further processed through different techniques such as cutting, forging, or machining to fabricate machine parts. These parts can include gears, shafts, valves, or any other component required for machinery. The use of steel billets in the manufacturing of machine parts offers several advantages. Firstly, steel billets are known for their high strength and durability, making them ideal for producing parts that can withstand heavy loads and harsh operating conditions. Additionally, the malleability of steel billets allows for the creation of intricate shapes and designs, ensuring the production of complex machine parts. Moreover, steel billets can be easily customized to meet specific requirements. They can be alloyed with other metals or undergo various heat treatments to enhance their properties such as hardness, corrosion resistance, or wear resistance. This versatility of steel billets makes them suitable for a wide range of machine parts across different industries. In conclusion, steel billets play a crucial role in the manufacturing of machine parts. Through processes such as hot rolling, cutting, forging, and machining, steel billets are transformed into various shapes and sizes to create durable and high-quality components for machinery. The versatility and strength of steel billets make them an indispensable raw material in the manufacturing industry.

Send your message to us

High quality steel billet product Q195 Q35

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords