Steel Billet Price Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet Price Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

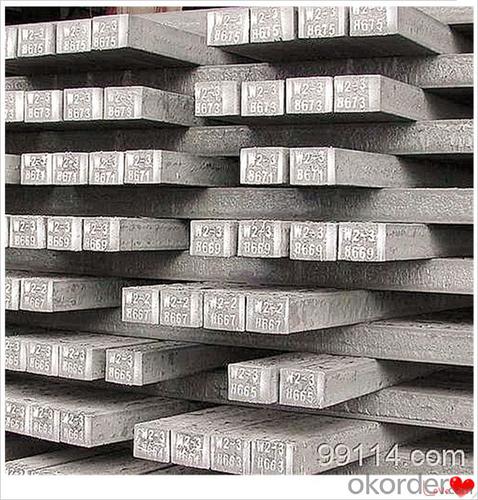

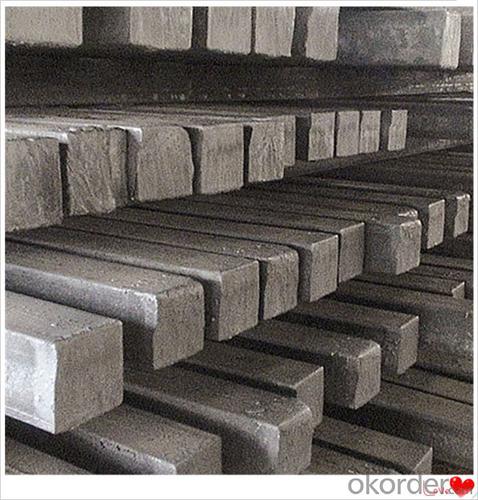

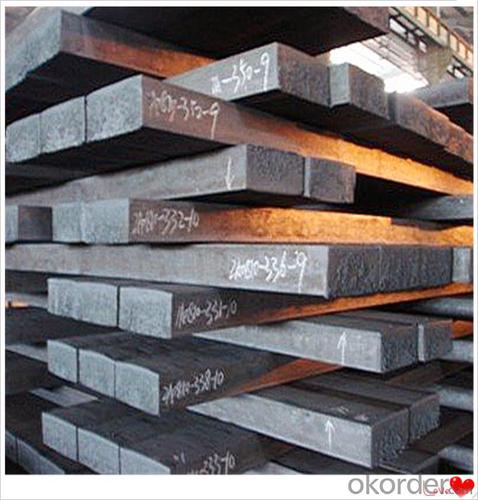

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

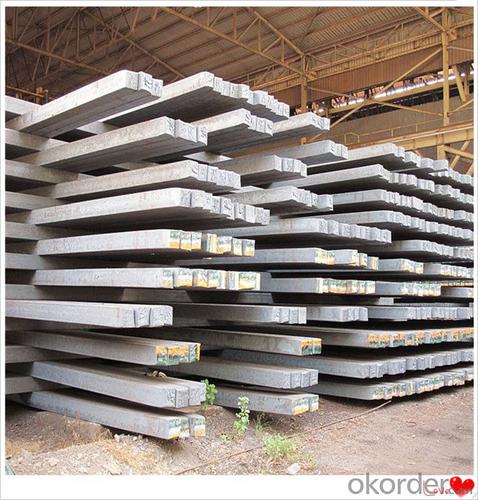

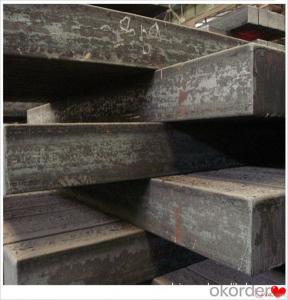

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

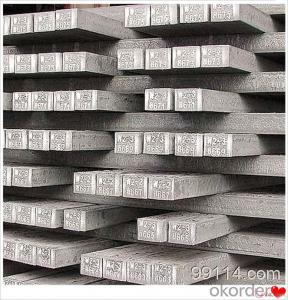

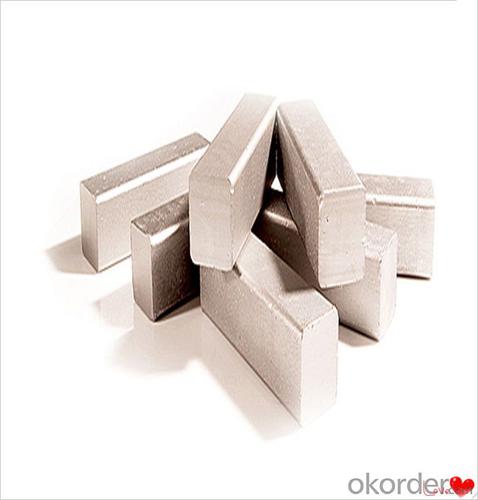

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the potential applications of steel billets in the oil and gas industry?

- The oil and gas industry can utilize steel billets in a wide range of ways. These include, but are not limited to, the following: 1. Manufacturing pipes: Steel billets can be used to create pipes that are crucial for transporting oil and gas. The strength and durability of steel make it an excellent choice for constructing pipes that can withstand the harsh conditions of drilling, extraction, and transportation. 2. Creating drill collars: Steel billets can be machined into drill collars, which are heavy steel tubes used in drilling. Drill collars provide weight to the drill string, increasing the force applied to the drill bit. The strength and toughness of steel billets make them suitable for this application, as they can withstand the high torque and pressure exerted during drilling. 3. Making downhole tools: Steel billets can also be used to manufacture a variety of downhole tools used in oil and gas exploration, including stabilizers, reamers, and subs. These tools are crucial for maintaining wellbore stability, clearing obstructions, and enhancing drilling efficiency. The ability of steel billets to withstand high temperatures, pressures, and abrasive environments makes them suitable for these tools. 4. Constructing offshore structures: Steel billets can be used in the construction of offshore platforms, jackets, and other structural components. These structures must withstand extreme weather conditions, corrosive environments, and heavy loads. Steel billets, with their high strength, corrosion resistance, and weldability, are an ideal choice for such applications. 5. Machining equipment and machinery components: Steel billets can be machined into various components and parts for oil and gas equipment and machinery. This includes valves, fittings, flanges, connectors, and other critical components used in drilling rigs, pipelines, refineries, and processing facilities. The versatility and reliability of steel make it a preferred material for such applications. In summary, steel billets have a wide range of potential applications in the oil and gas industry. Their high strength, durability, corrosion resistance, and versatility make them essential in pipe manufacturing, the creation of drill collars and downhole tools, the construction of offshore structures, and the machining of equipment components. Steel billets play a crucial role in ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q: How are steel billets packaged for shipment?

- Steel billets are typically packaged for shipment by placing them on wooden pallets or in steel cages. They are then secured using steel strapping or shrink wrap to prevent movement or damage during transportation. Labels are also attached to the packaging to identify the type, quantity, and destination of the billets.

- Q: How are steel billets used in the production of marine parts?

- Steel billets serve as a vital element in the manufacturing process of marine parts. These semi-finished steel products act as the raw material for shaping and forming a variety of marine components. To commence, steel billets undergo a procedure known as hot rolling. This involves subjecting them to high temperatures and passing them through rolling mills to attain different shapes and sizes. By undergoing hot rolling, the steel's grain structure is refined, thereby enhancing its mechanical properties and rendering it suitable for marine applications. Once the desired shape and size are achieved, these billets are further processed using various techniques such as forging, machining, and welding to create specific marine parts. Propeller shafts, rudder stocks, hull frames, and bulkheads are examples of marine components produced using steel billets. The exceptional strength and durability of steel make it an excellent choice for manufacturing marine parts, as it can withstand the harsh conditions of saltwater, extreme temperatures, and heavy loads. Moreover, steel billets can be easily customized to meet specific design requirements, ensuring the production of precise and dependable marine parts. Additionally, steel billets play a crucial role in the repair and maintenance of marine vessels. When existing components need replacement, steel billets can be shaped and machined to match the exact specifications of the original parts. This guarantees compatibility and seamless integration, facilitating efficient repairs and ensuring the uninterrupted operation of marine vessels. In conclusion, steel billets are indispensable in the production of marine parts as they provide the necessary raw material for shaping and forming various components. The combination of high strength, durability, and customization capabilities makes steel billets an ideal choice for marine applications, ensuring the reliability and performance of marine vessels.

- Q: How are steel billets used in the production of pressure vessels?

- Due to their remarkable strength and durability, steel billets are commonly utilized in the production of pressure vessels. Pressure vessels, such as tanks or containers, are specifically designed to store or transport fluids or gases under high pressures. To manufacture pressure vessels, the initial step involves heating steel billets and subjecting them to a process known as hot rolling. This process entails passing the billets through a series of rollers in order to shape them into the desired form. The hot rolling process not only imparts the final shape to the billets but also enhances their mechanical properties, thereby making them more suitable for withstanding high pressures. Following the hot rolling process, the billets undergo further processing using a variety of techniques, including forging, machining, and welding. These techniques are employed to create the necessary components of the pressure vessel, such as the shell, heads, nozzles, and other fittings. The preference for steel billets in pressure vessel production stems from their high tensile strength and resistance to deformation. This ensures that the vessel can endure the internal pressure without experiencing any structural failure. Additionally, steel billets are capable of withstanding a wide range of temperatures, rendering them suitable for diverse applications involving pressure vessels. In addition to their mechanical properties, steel billets also possess exceptional corrosion resistance. This quality is crucial for pressure vessels, as they often come into contact with corrosive substances or environments. By utilizing corrosion-resistant steel billets, the lifespan of the pressure vessel is extended, thereby reducing the frequency of maintenance and replacement. In conclusion, the utilization of steel billets is of utmost importance in the production of pressure vessels, as they provide the necessary strength, durability, and corrosion resistance required for the safe storage or transportation of fluids or gases under high pressures.

- Q: How are steel billets cut to size?

- Steel billets are typically cut to size using various methods such as sawing, torch cutting, shearing, or using automated machines like bandsaws or plasma cutting machines.

- Q: How are steel billets used in the production of railway parts?

- Steel billets are an important raw material used in the production of railway parts. These billets are essentially semi-finished steel products that are cast into a specific shape and size, typically in a square or rectangular form. They serve as the starting point for the manufacturing process of various railway components. One of the primary applications of steel billets in the production of railway parts is for the manufacturing of rails. The billets are heated and then passed through a series of rolling mills to shape them into the desired rail profile. This process, known as rolling, involves applying pressure to the billet, which gradually elongates and shapes it into the rail section. The resulting rails are then cut to the required length and undergo further processes such as heat treatment and finishing to enhance their strength and durability. Apart from rails, steel billets are also used in the production of other crucial railway components such as wheels, axles, and various structural parts. For example, billets can be forged or machined to form the wheel blanks, which are subsequently processed to create the final wheel shape. Similarly, billets can be used to manufacture axles by forging and machining them into the desired dimensions and specifications. Additionally, steel billets may be employed in the fabrication of various structural parts used in railway infrastructure, including bridges, tunnels, and platforms. These billets are processed through different manufacturing techniques such as casting, forging, or machining to produce the required components. In summary, steel billets play a vital role in the production of railway parts. From manufacturing rails to wheels, axles, and structural components, these billets serve as the starting material that undergoes various shaping, heat treatment, and finishing processes to create the final railway components that ensure safe and efficient transportation.

- Q: How are steel billets used in the production of marine equipment?

- Steel billets are an integral part of the production process for marine equipment. These billets, which are semi-finished steel products, serve as the raw material for manufacturing different components used in the construction of marine equipment such as ships, offshore platforms, and marine structures. Firstly, steel billets are used to create various structural elements of marine equipment, including hulls, decks, and bulkheads. These components provide the strength and stability necessary to withstand the harsh conditions of marine environments. The billets are heated and shaped through processes like rolling, forging, or extrusion to form the desired shapes and sizes of these structural elements. Additionally, steel billets are used to produce propeller shafts, rudders, and other propulsion system components. These parts are crucial for the movement and maneuverability of marine equipment. The billets are machined and further processed to create these specialized components, ensuring their durability and reliability in demanding marine conditions. Moreover, steel billets are employed in the production of marine equipment accessories such as anchors, chains, and mooring systems. These accessories play a vital role in ensuring the stability and safety of vessels and offshore structures. The billets are transformed into the required shapes and sizes through casting, forging, or machining processes to meet the specific requirements of each accessory. Furthermore, steel billets are also utilized in the manufacturing of marine equipment fittings, including valves, pipes, and fittings for fluid and gas systems. These components are essential for the proper functioning of various systems on board vessels, such as fuel, water, and hydraulic systems. The billets are processed and machined to create these fittings, ensuring their compatibility with marine-grade materials and their ability to withstand corrosive marine environments. In summary, steel billets are crucial in the production of marine equipment as they serve as the primary raw material for creating structural elements, propulsion system components, accessories, and fittings. By using steel billets, manufacturers can ensure the strength, durability, and reliability of marine equipment, enabling them to withstand the challenging conditions of the marine environment and ensuring the safety and performance of vessels and offshore structures.

- Q: How does the market demand for steel billets fluctuate over time?

- The market demand for steel billets fluctuates over time due to various factors such as economic conditions, industrial growth, infrastructure projects, and global trade dynamics. During periods of economic growth and expansion, there is typically an increased demand for steel billets as it is a crucial raw material for construction, manufacturing, and transportation sectors. Conversely, during economic downturns or recessions, the demand may decrease as construction projects are delayed, manufacturing activities reduce, and consumer spending declines. Additionally, market demand for steel billets can be influenced by changes in government policies, trade tariffs, and technological advancements in alternative materials. Overall, the market demand for steel billets is subject to cyclical fluctuations driven by economic conditions and industrial activities.

- Q: Can steel billets be used in the production of industrial equipment?

- Yes, steel billets can be used in the production of industrial equipment. Steel billets are semi-finished metal products that can be further processed to create various types of industrial equipment such as machinery, tools, automotive parts, construction materials, and more. The high strength, durability, and versatility of steel make it an ideal material for manufacturing industrial equipment. Steel billets can be shaped, machined, and welded to create complex structures and components, providing the necessary strength and stability required for industrial applications. Additionally, steel billets can be heat-treated to enhance their mechanical properties, making them even more suitable for use in heavy-duty industrial equipment.

- Q: How is a steel billet made?

- A steel billet is made through a process called continuous casting. It involves pouring molten steel into a water-cooled mold, which solidifies the steel into a rectangular shape. The solidified steel is then cut to the desired length to form a steel billet.

Send your message to us

Steel Billet Price Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords