Q275 Steel Billets Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Q275 Steel Billets Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

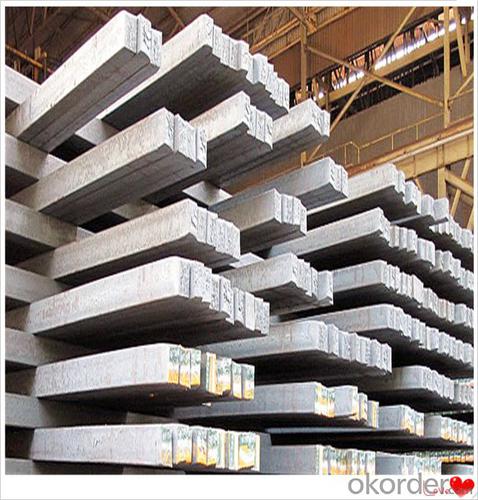

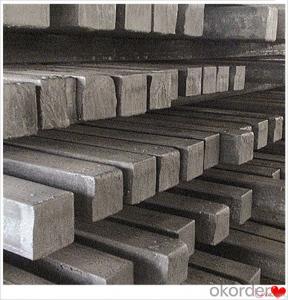

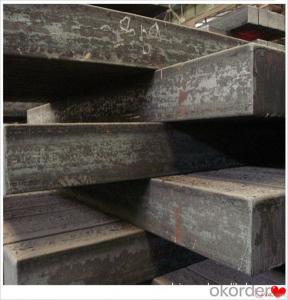

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the potential applications of steel billets in the chemical sector?

- Steel billets have a wide range of potential applications in the chemical sector. One of the main uses of steel billets is in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets are highly durable and can withstand the corrosive nature of many chemicals, making them ideal for this purpose. Additionally, steel billets can be used in the construction of pipes and tubing systems for chemical processing plants. These pipes and tubing systems are used to transport various chemicals throughout the facility and need to be able to withstand high pressures and temperatures. Steel billets provide the strength and durability required for these applications. Another potential application of steel billets in the chemical sector is in the production of chemical reactors. Chemical reactors are used in the manufacturing of various chemicals and require materials that can handle the harsh conditions involved in chemical reactions. Steel billets can be used to construct these reactors, providing the necessary strength and resistance to corrosion. Furthermore, steel billets can be utilized in the fabrication of various equipment used in the chemical sector, such as heat exchangers, distillation columns, and pumps. These equipment are essential for the processing and production of chemicals, and steel billets provide the necessary strength and reliability required for their operation. Overall, the potential applications of steel billets in the chemical sector are vast and varied. Their durability, strength, and resistance to corrosion make them an ideal choice for various construction and fabrication purposes in chemical processing plants, storage facilities, and equipment manufacturing.

- Q: What is the role of steel billets in the manufacturing of conveyor systems?

- Steel billets play a crucial role in the manufacturing of conveyor systems. These billets serve as the raw material for the production of various components and parts that make up the conveyor system. Firstly, steel billets are used to create the framework and structure of the conveyor system. They are shaped and cut to form the main frame, supports, and other structural elements that provide stability and strength to the entire system. The high strength and durability of steel make it an ideal material for this purpose, ensuring that the conveyor system can withstand heavy loads and operate efficiently. Secondly, steel billets are utilized in the production of rollers and pulleys, which are essential components of conveyor systems. These rollers and pulleys are responsible for guiding and moving the conveyor belt, enabling the smooth and continuous flow of materials. Steel billets are forged and machined to create these components, ensuring their reliability and longevity even under demanding working conditions. Additionally, steel billets are also used to manufacture various brackets, connectors, and fasteners that hold the different parts of the conveyor system together. These components provide the necessary connections and attachments, ensuring the proper assembly and functioning of the conveyor system. Furthermore, steel billets can be molded and shaped into customized parts as per the specific requirements of the conveyor system. This flexibility allows conveyor manufacturers to design and produce conveyor systems that are tailored to the unique needs of different industries and applications. In summary, steel billets are integral to the manufacturing of conveyor systems as they provide the raw material for the construction of the system's framework, rollers, pulleys, brackets, connectors, and other components. Their high strength, durability, and flexibility make steel billets an essential ingredient in creating reliable and efficient conveyor systems.

- Q: Can steel billets be used in the production of railway tracks?

- Yes, steel billets can be used in the production of railway tracks. Steel billets are semi-finished products that are commonly used in the manufacturing of various steel products, including railway tracks. Railway tracks require high strength and durability to withstand the weight and movement of trains. Steel billets, which are typically made from carbon steel or alloy steel, provide the necessary strength and structural integrity required for railway tracks. These billets can be further processed and shaped into rails through hot rolling or other manufacturing processes. The final rails are then installed on railway tracks to provide a smooth and safe surface for train movement. Therefore, steel billets are an essential raw material in the production of railway tracks.

- Q: Can steel billets be used in the manufacturing of machinery?

- Steel billets have the capability to be utilized in the production of machinery. These semi-finished metal products are typically either hot rolled or forged into various shapes, such as bars, rods, or sheets. Machinery components like gears, shafts, bearings, and structural frames are manufactured using these billets as the raw material. The utilization of steel billets in machinery manufacturing offers numerous benefits. Steel is renowned for its exceptional strength, durability, and resistance to wear, making it a suitable choice for heavy-duty applications. Furthermore, steel can be easily machined, welded, and molded into intricate shapes, facilitating the production of complex machinery parts. Moreover, due to its high melting point and thermal conductivity, steel is an ideal material for applications involving high temperatures or requiring heat transfer. Overall, steel billets are extensively employed in machinery manufacturing due to their outstanding mechanical properties, versatility, and dependability.

- Q: How do steel billets contribute to the overall corrosion protection of a structure?

- Steel billets, which are semi-finished steel products, play a significant role in contributing to the overall corrosion protection of a structure. They contribute to corrosion protection in several ways: 1. High-quality steel composition: Steel billets are manufactured using high-quality steel that consists of various alloying elements, such as chromium, nickel, and molybdenum. These alloying elements enhance the corrosion resistance of the steel, making it less susceptible to rust and corrosion. 2. Protective coating: Steel billets are often coated with protective layers, such as zinc or epoxy coatings. These coatings act as a barrier between the steel surface and the external environment, preventing moisture, oxygen, and other corrosive substances from reaching the steel and causing corrosion. 3. Durability and strength: Steel billets are known for their high strength and durability. When used in the construction of a structure, they provide a strong foundation and structural support. This strength and durability minimize the chances of structural damage and corrosion, ensuring the longevity and stability of the structure. 4. Weldability: Steel billets are highly weldable, allowing for easy and efficient joining of steel components during construction. Proper welding techniques and materials can further enhance the corrosion resistance of the structure by maintaining the integrity and continuity of the protective coatings. 5. Maintenance and repair: In case of any damage or corrosion on the structure, steel billets can be easily replaced or repaired. This ensures that the affected area can be fixed without compromising the overall integrity and corrosion protection of the structure. Regular maintenance and repair of steel billets contribute to the long-term corrosion protection of the entire structure. In summary, steel billets contribute to the overall corrosion protection of a structure through their high-quality composition, protective coatings, durability, weldability, and ease of maintenance and repair. By incorporating steel billets into construction projects, engineers and architects can ensure the longevity, safety, and corrosion resistance of structures in various environments.

- Q: What is the role of steel billets in the production of railway wagons?

- Steel billets play a critical role in the production of railway wagons as they serve as the raw material for manufacturing various components, such as the wagon body, chassis, and structural elements. These billets are heated and shaped into desired forms through processes like rolling and forging, which enable the creation of strong and durable wagon parts. By providing the necessary strength and structural integrity, steel billets contribute to the overall safety, reliability, and longevity of railway wagons, ensuring they can withstand the demanding conditions and heavy loads encountered during their service on the railways.

- Q: What are the different surface treatments for improved formability in steel billets?

- Some of the different surface treatments for improved formability in steel billets include hot rolling, cold rolling, annealing, and pickling. These treatments help to enhance the plasticity and ductility of the steel, making it easier to shape and form into desired products.

- Q: What are the factors that affect the quality of steel billets?

- There are several factors that can affect the quality of steel billets, which are semi-finished metal products used in the production of various steel products. Some of the key factors include: 1. Raw materials: The quality of steel billets is heavily influenced by the quality of the raw materials used in their production. The composition of the steel, such as the percentage of carbon and other alloying elements, plays a crucial role in determining the final quality of the billets. 2. Manufacturing process: The manufacturing process used to produce steel billets can significantly impact their quality. Factors such as the temperature, pressure, and duration of the heating and cooling processes, as well as the rate of solidification, can affect the internal structure and mechanical properties of the billets. 3. Quality control measures: The implementation of effective quality control measures throughout the production process is essential for ensuring the quality of steel billets. Regular inspections, testing, and monitoring of critical parameters, such as dimensions, surface finish, and chemical composition, help identify any deviations from the desired specifications and allow for corrective actions to be taken. 4. Equipment and technology: The quality of the equipment and technology used in the production of steel billets can have a significant impact on their quality. Advanced machinery and techniques, such as continuous casting or vacuum degassing, can improve the homogeneity and cleanliness of the billets, resulting in higher-quality products. 5. Environmental conditions: Environmental factors, such as temperature, humidity, and cleanliness of the production environment, can also affect the quality of steel billets. Contaminants, such as dust, pollutants, or moisture, can adversely impact the surface finish and overall quality of the billets. 6. Handling and storage: Proper handling and storage practices are crucial for maintaining the quality of steel billets. Any mishandling, such as dropping or rough handling, can lead to surface defects or internal damage. Similarly, improper storage conditions, such as exposure to moisture or corrosive substances, can deteriorate the quality of the billets. In conclusion, the quality of steel billets is influenced by a combination of factors, including the raw materials, manufacturing process, quality control measures, equipment and technology, environmental conditions, and handling and storage practices. By carefully considering and optimizing these factors, steel manufacturers can produce high-quality billets that meet the desired specifications and customer requirements.

- Q: What are the main factors affecting the hardenability of stainless steel billets?

- The hardenability of stainless steel billets, which refers to the material's ability to be hardened through heat treatment, can be influenced by various factors. These factors include: 1. Alloy composition: The composition of stainless steel, especially the presence of carbon, chromium, nickel, and molybdenum, plays a crucial role in determining its hardenability. Higher carbon content generally improves hardenability, while elements like chromium and nickel enhance corrosion resistance but may decrease hardenability. 2. Grain size: The grain size of stainless steel billets affects the rate and depth of hardening. Finer grain structures typically exhibit better hardenability compared to coarser ones. This is because smaller grains allow for a more even distribution of carbon and alloying elements, resulting in improved hardening response. 3. Heat treatment conditions: The specific heat treatment process utilized, including heating and cooling rates, soaking time, and quenching media, has a significant impact on the hardenability of stainless steel billets. Proper control of these parameters is essential to achieve the desired hardness and mechanical properties. 4. Cooling rate: The rate at which the billets are cooled during the quenching process is a critical factor in determining their hardenability. Rapid quenching, such as water or oil quenching, promotes martensitic transformation and leads to greater hardness. Slower cooling rates, such as air cooling, result in a softer and less hardened structure. 5. Cross-sectional thickness: The thickness of the stainless steel billets also affects their hardenability. Thicker sections tend to have lower hardenability due to slower heat transfer rates during quenching. Conversely, thinner sections can achieve higher hardness levels due to faster cooling rates. 6. Prior microstructure: The initial microstructure of the stainless steel billets, whether they are in an annealed or cold-worked state, can influence hardenability. Cold work can introduce dislocations and grain boundaries, which may impede the diffusion of carbon and alloying elements during heat treatment, leading to reduced hardenability. Considering these factors, manufacturers and engineers must carefully select stainless steel grades and tailor the heat treatment process to achieve the desired level of hardenability and mechanical properties in stainless steel billets.

- Q: What is the purpose of steel billets?

- The purpose of steel billets is to serve as raw material for various metalworking processes, such as forging, rolling, and extrusion. They are typically heated and shaped into different forms to create finished steel products like bars, rods, wire, and pipes.

Send your message to us

Q275 Steel Billets Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords