Stainless Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China Supplier

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

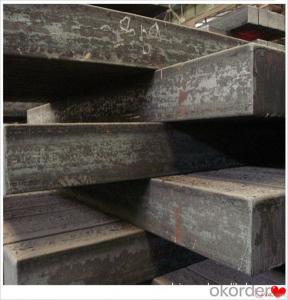

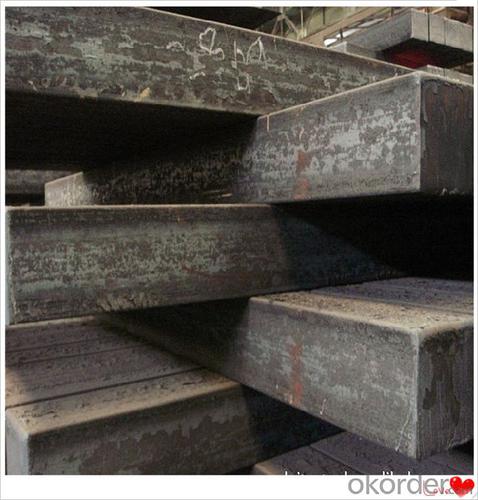

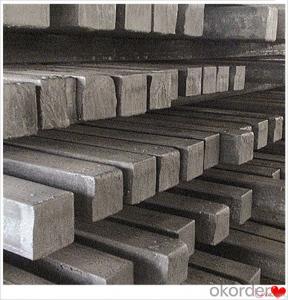

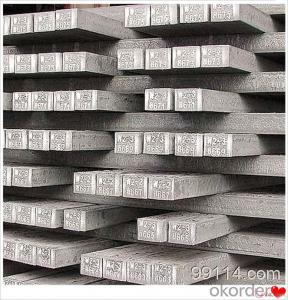

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the different methods of steel billet surface honing?

- There are several methods of steel billet surface honing, including manual honing, machine honing, and diamond honing. Manual honing involves using hand-held tools, such as honing stones or abrasive pads, to manually remove imperfections and create a smooth surface on the steel billet. Machine honing utilizes automated machines with rotating honing tools to achieve a consistent and precise surface finish. Diamond honing, on the other hand, uses diamond abrasive stones or pads to achieve a high-quality and precise surface finish on the steel billet. Each method has its own advantages and is chosen based on the specific requirements and desired outcome of the honing process.

- Q: Can steel billets be used in the manufacturing of machinery?

- Yes, steel billets can be used in the manufacturing of machinery. Steel billets are semi-finished products that can be further processed into various shapes and sizes for different applications. In machinery manufacturing, steel billets are often used as raw materials to produce components such as gears, shafts, and structural frames. The high strength and durability of steel make it an ideal choice for machinery that requires robust construction and reliable performance.

- Q: What are the main factors affecting the strength of steel billets?

- There are several main factors that can affect the strength of steel billets. 1. Composition: The chemical composition of the steel, including the types and amounts of various elements, plays a significant role in determining its strength. Alloying elements such as carbon, manganese, and silicon can enhance the strength of steel by forming solid solutions or creating carbides, which increase the steel's hardness and resistance to deformation. 2. Heat treatment: The heat treatment process, which involves heating and cooling the steel billets under controlled conditions, can have a significant impact on its strength. Different heat treatment methods, such as annealing, quenching, and tempering, can alter the microstructure of the steel, leading to variations in its strength properties. 3. Grain size: The size and distribution of the grains within the steel structure can affect its strength. Smaller grain sizes tend to increase the strength of steel, as they hinder dislocation movement and promote grain boundary strengthening. Various processing techniques, such as hot rolling and controlled cooling, can be employed to achieve fine-grained steel billets. 4. Microstructure: The microstructure of steel, which includes the arrangement and morphology of the different phases or constituents, can influence its strength. For example, the presence of certain phases like martensite or bainite can significantly increase the strength of steel by providing a more rigid and stable structure. 5. Processing conditions: The processing conditions during the production of steel billets can impact their strength. Variables such as rolling temperature, deformation rate, and cooling rate can affect the microstructural evolution and mechanical properties of the steel. Proper control of these processing parameters is crucial to achieving the desired strength characteristics. 6. Inclusions and defects: The presence of inclusions or defects, such as non-metallic particles or voids, within the steel can weaken its strength. These imperfections act as stress concentrators and can initiate cracks or fractures, reducing the overall strength and integrity of the steel billets. By considering and optimizing these factors, manufacturers can produce steel billets with enhanced strength properties, enabling their use in various applications where high strength and durability are required.

- Q: How are steel billets forged into shape?

- Steel billets are forged into shape through a process called hot forging, which involves heating the billet to a specific temperature and then applying pressure to shape it using a forging press or hammer. This process helps to refine the grain structure of the steel, improving its strength and mechanical properties.

- Q: What are the factors affecting the price of steel billets?

- There are several factors that can affect the price of steel billets. 1. Supply and demand: Like any other commodity, the price of steel billets is influenced by the balance between supply and demand. If the demand for steel billets is high and the supply is limited, the price will increase. Conversely, if the supply exceeds the demand, the price will decrease. 2. Raw material costs: The cost of the raw materials used to produce steel billets, such as iron ore and coal, can significantly impact the price. Fluctuations in the prices of these raw materials can lead to changes in the cost of production, which in turn affects the price of steel billets. 3. Energy prices: The production of steel billets requires a significant amount of energy, particularly in the form of electricity and fuel. Therefore, changes in energy prices can have a direct impact on the price of steel billets. For example, if energy prices increase, the cost of production for steel billets will also rise, leading to a higher price. 4. Transportation costs: The cost of transporting steel billets from the manufacturing plant to the market can also affect the final price. Factors such as fuel prices, distance, and transportation infrastructure can impact the transportation costs and subsequently influence the price of steel billets. 5. Government regulations and trade policies: Government regulations, such as import/export duties, tariffs, and quotas, can have a significant impact on the price of steel billets. These policies can restrict or facilitate the movement of steel billets between countries, affecting the supply and demand dynamics and, consequently, the price. 6. Currency exchange rates: Steel billets are traded globally, and fluctuations in currency exchange rates can impact their price. If the currency in which steel billets are traded weakens against other currencies, the price of steel billets may increase to compensate for the decreased value of the currency. 7. Market speculation and investor sentiment: The price of steel billets, like any other commodity, can also be influenced by market speculation and investor sentiment. Factors such as economic indicators, geopolitical events, and investor expectations can drive buying or selling behavior, leading to price fluctuations. It is important to note that these factors are interconnected and can interact with each other, creating a complex and dynamic market for steel billets.

- Q: Can steel billets be used for making kitchen utensils?

- Yes, steel billets can be used for making kitchen utensils. Steel billets are raw materials that can be shaped and formed into various products, including kitchen utensils. The steel used for kitchen utensils needs to be of high quality, with properties such as corrosion resistance, durability, and heat resistance. Steel billets can be melted, cast, and then forged into desired shapes and sizes for making kitchen utensils like knives, spoons, forks, cookware, and more. The steel used in kitchen utensils is often treated and finished to enhance its performance and appearance. Overall, steel billets serve as a starting point in the manufacturing process of kitchen utensils, providing the necessary raw material for creating durable and functional tools for cooking and food preparation.

- Q: How do steel billets compare to other types of raw materials in manufacturing?

- Steel billets, recognized extensively as one of the most versatile and commonly utilized raw materials in manufacturing industries, possess various advantages that render them highly sought after. To begin with, the extraordinary strength and durability of steel billets make them suitable for a diverse array of applications, such as construction, automotive, and machinery manufacturing. Boasting high tensile strength, steel billets ensure the structural integrity of the final product. Furthermore, steel billets exhibit exceptional heat resistance, making them ideal for sectors involving exposure to extreme temperatures, such as aerospace and energy industries. These billets can endure high temperatures without compromising their mechanical properties, guaranteeing the longevity and reliability of the manufactured goods. Additionally, steel billets possess high malleability and can be effortlessly shaped into numerous forms through processes like rolling, forging, or extrusion. This versatility enables manufacturers to fabricate intricate and complex parts, components, and structures, catering to the diverse needs of various industries. Moreover, steel billets are readily available in substantial quantities, making them a cost-effective option for manufacturing. The abundance of steel billets in the market ensures a stable supply chain, mitigating potential disruptions caused by material shortages. Lastly, steel billets are renowned for their recyclability, rendering them an environmentally friendly choice. Steel stands as one of the most recycled materials globally, and the utilization of steel billets in manufacturing contributes to reducing the environmental impact of waste disposal, while conserving natural resources. In conclusion, the exceptional strength, heat resistance, malleability, cost-effectiveness, and recyclability of steel billets surpass other types of raw materials in manufacturing. These qualities establish steel billets as the preferred choice for a wide range of industries, offering reliability, versatility, and sustainability throughout the manufacturing process.

- Q: What is the role of steel billets in the manufacturing of storage systems?

- The manufacturing of storage systems heavily relies on steel billets due to their unique properties and versatility. These billets, which are semi-finished steel products, are essential raw materials used in various manufacturing processes. An important function of steel billets in the manufacturing of storage systems is to act as the base material for producing different components like shelves, frames, supports, and racks. The strength and durability of steel make it an excellent choice for these applications as it can endure heavy loads and offer long-lasting performance. Typically, steel billets are melted and cast into specific shapes, such as square or round, to meet the requirements of the storage system design. These billets then undergo additional processing, like hot rolling, to transform them into the desired dimensions and form. This process helps refine the steel's microstructure, enhancing its mechanical properties and ensuring consistent quality. The versatility of steel billets allows manufacturers to customize storage systems according to specific needs. By shaping and welding steel billets, manufacturers can create storage systems with various configurations, sizes, and load capacities. This flexibility enables the production of storage systems tailored for different industrial and commercial applications, ranging from warehouses to retail stores. Furthermore, steel billets exhibit excellent resistance to corrosion, making them suitable for storage systems used in both indoor and outdoor environments. This resistance ensures that the storage systems maintain their structural integrity and appearance over time, even in harsh conditions. In conclusion, steel billets play a crucial role in the manufacturing of storage systems as they serve as the raw material for various components. Their strength, durability, versatility, and corrosion resistance make them an ideal choice for fabricating storage systems capable of withstanding heavy loads, providing long-lasting performance, and meeting specific design requirements.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- The main deformation of reinforced by ribs, binding capacity larger and concrete, so it can better withstand external force. Steel is widely used in all kinds of building structure, especially for large, heavy, light and thin wall structure of high-rise building.

- Q: How do steel billets contribute to the sustainability of construction projects?

- Steel billets contribute to the sustainability of construction projects in several ways. First, steel is an incredibly durable and long-lasting material. Steel billets are the raw form of steel that can be used to manufacture various construction components such as beams, columns, and reinforcement bars. These components provide structural integrity and strength to buildings, ensuring their longevity. By using steel billets, construction projects can be built to withstand extreme weather conditions and natural disasters, reducing the need for frequent repairs or replacements. This durability directly contributes to the sustainability of construction projects by reducing waste and conserving resources over time. Second, steel is a highly recyclable material. Steel billets can be recycled and reused indefinitely without losing their quality or performance. Recycling steel reduces the energy consumption, greenhouse gas emissions, and waste associated with the production of new steel. By incorporating recycled steel billets into construction projects, the demand for virgin steel can be reduced, thereby conserving natural resources and minimizing environmental impact. Additionally, the use of steel billets in construction allows for efficient and versatile designs. Steel is known for its high strength-to-weight ratio, allowing for lighter and slimmer structural elements that require fewer materials. This not only reduces the overall weight of the building, but also decreases the amount of concrete and other construction materials required. As a result, less energy is consumed in the production and transportation of these materials, leading to a more sustainable construction process. Furthermore, steel is resistant to pests, such as termites and fungi, which can cause significant damage to buildings. By using steel billets, construction projects can avoid the use of chemical treatments typically required to protect wooden structures, reducing the environmental impact of pest control measures. In conclusion, steel billets contribute to the sustainability of construction projects through their durability, recyclability, efficient design possibilities, and resistance to pests. By incorporating steel into construction, buildings can be built to last, reduce waste, conserve resources, and minimize environmental impact.

Send your message to us

Stainless Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords